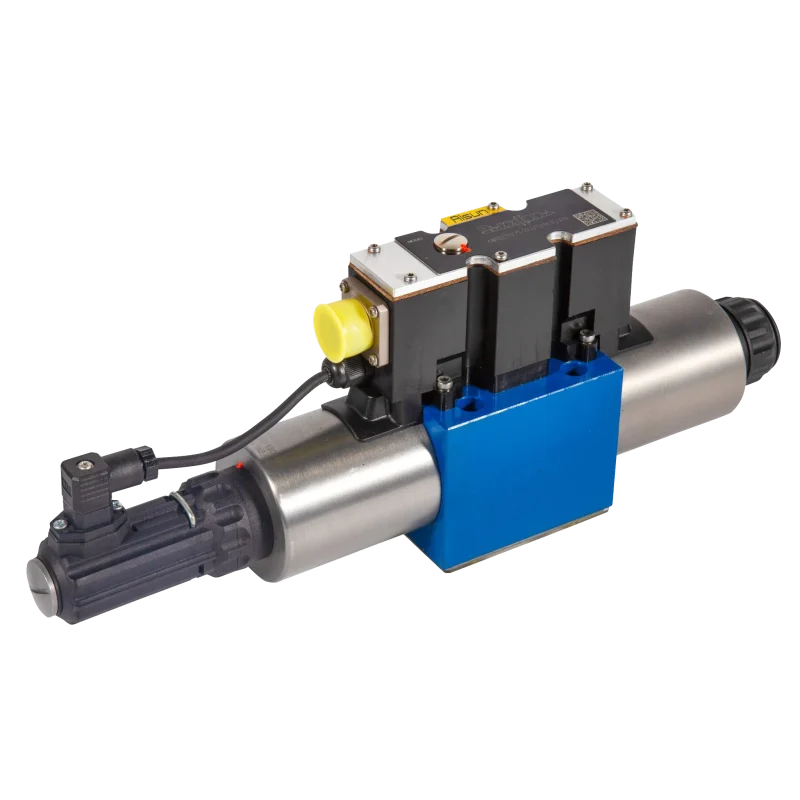

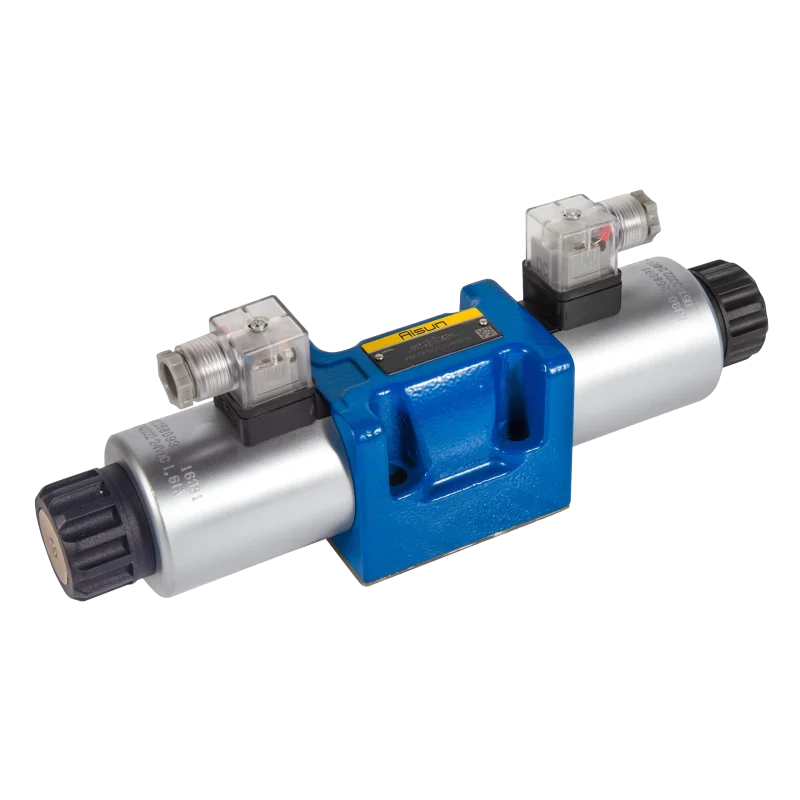

Servo Valve D761

Features of the D761 Hydraulic Servo Valve:

1. Functionality:

o The D761 valve typically controls the flow of hydraulic fluid to a hydraulic actuator, such as a cylinder or motor.

o The position of the valve spool is adjusted based on an input control signal (often electrical), which influences the amount and direction of hydraulic fluid passing through the valve.

o The output flow is proportional to the input control signal, allowing fine control over the actuator’s motion, position, or force.

2. Proportional Control:

o It is a proportional valve, meaning that the flow and pressure are continuously adjustable in proportion to the electrical signal (current or voltage) supplied to the valve’s solenoids.

o The D761 can handle both position and force control, making it suitable for applications requiring precise regulation.

3. High Precision:

o These valves are designed for high-precision applications. The flow is finely controlled, making them ideal for systems where even small adjustments in flow or pressure can have significant impacts on system performance.

o The D761 servo valve is typically characterized by high resolution, quick response times, and minimal hysteresis (the delay between input and output).

4. Two-Stage Design:

o Many hydraulic servo valves, including the D761, feature a two-stage design. The first stage is a low-flow, high-precision control stage, while the second stage involves a power stage that provides the high flow required to actuate the system.

o This ensures that the valve can handle both fine control and high flow, making it versatile for a wide range of applications.

5. Feedback Mechanism:

o Servo valves like the D761 are often equipped with feedback systems to ensure accurate positioning. This feedback system continuously monitors the spool position and adjusts it to minimize error between the desired and actual output.

o This feedback loop allows for stable operation even in the presence of external disturbances or load variations.

6. High Flow Capacity:

o The D761 series is designed to accommodate high flow rates, which makes it suitable for use in larger hydraulic systems that require both precise control and high throughput of fluid.

7. Application Areas:

o Aerospace (e.g., flight control systems)

o Robotics (e.g., precise motion control in robotic arms)

o Industrial machinery (e.g., CNC machines or testing rigs)

o Automotive (e.g., for testing or control in hydraulic suspension systems)

Advantages of D761 Hydraulic Servo Valves:

• Precision and Accuracy: The valve allows for extremely fine control of fluid flow, ideal for applications requiring tight regulation.

• Fast Response Time: The servo valve’s quick reaction to input changes enables it to operate effectively in dynamic systems.

• Robustness: Designed for high-pressure applications, these valves can handle the demands of industrial and aerospace environments.

• Scalability: The D761 series is available in a variety of configurations to meet the specific needs of different systems.

hydraulic Servo Directional valves D761

Servo Directional valves D761

The Servo Directional valves D761 is a precision valve commonly used in hydraulic control systems to regulate fluid flow in response to electrical input signals. It is part of the family of servo valves, which are designed to offer high-performance control in applications where precise motion or position control is required. These valves are used in a wide range of industries, including aerospace, industrial automation, robotics, and more.