and powerfull

Our top products

Various products

in all sizes

Design and manufacture

of valves and manifolds

Design & manufacture of standvalve types

Ending soon

Remaining time for special deal products. Hurry up!days

hours

minutes

Featured products

-

Check Valve RVP

Rated 4.00 out of 5$66 – $229Price range: $66 through $229Check Valve RVP

Applications in Hydraulic Systems: The RVP type check valve finds widespread utility in hydraulic systems, primarily at the outlet of pumps. Here, it serves a dual purpose as a back pressure valve and bypass valve. As a back pressure valve, it helps regulate the pressure within the hydraulic circuit, ensuring optimal performance and preventing potential damage due to excessive pressure. Simultaneously, its role as a bypass valve allows for the controlled diversion of fluid when needed, adding flexibility to the hydraulic setup.

-

check valve s

$8 – $38Price range: $8 through $38check valve s

A check valve, also known as a non-return valve or one-way valve, is designed to allow fluid to flow in only one direction through a pipeline. This valve is crucial for preventing backflow, which is the reverse flow of fluids that can lead to contamination and inefficiency in the system. Historically, it have been utilized since ancient times, primarily in water control for irrigation systems. Their design and functionality have evolved significantly, making them indispensable in modern industries such as oil and gas, chemical processing, water treatment, and HVAC systems .

-

Check Valve Sl

$7 – $206Price range: $7 through $206Check Valve Sl

The Aisun Model SL check valve is a high-performance hydraulic valve designed to prevent the reverse flow of fluid in a hydraulic circuit. It allows fluid to flow in one direction while automatically blocking any fluid flow in the opposite direction. This prevents damage to pumps, motors, and other components in the system that could be caused by backflow.

-

Check Valve Sv

$62 – $209Price range: $62 through $209Check Valve Sv

The Aisun Model Sv check valve is a high-performance hydraulic valve designed to prevent the reverse flow of fluid in a hydraulic circuit. It allows fluid to flow in one direction while automatically blocking any fluid flow in the opposite direction. This prevents damage to pumps, motors, and other components in the system that could be caused by backflow.

-

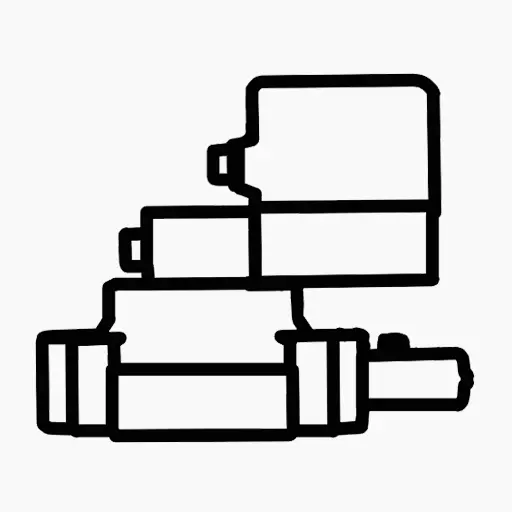

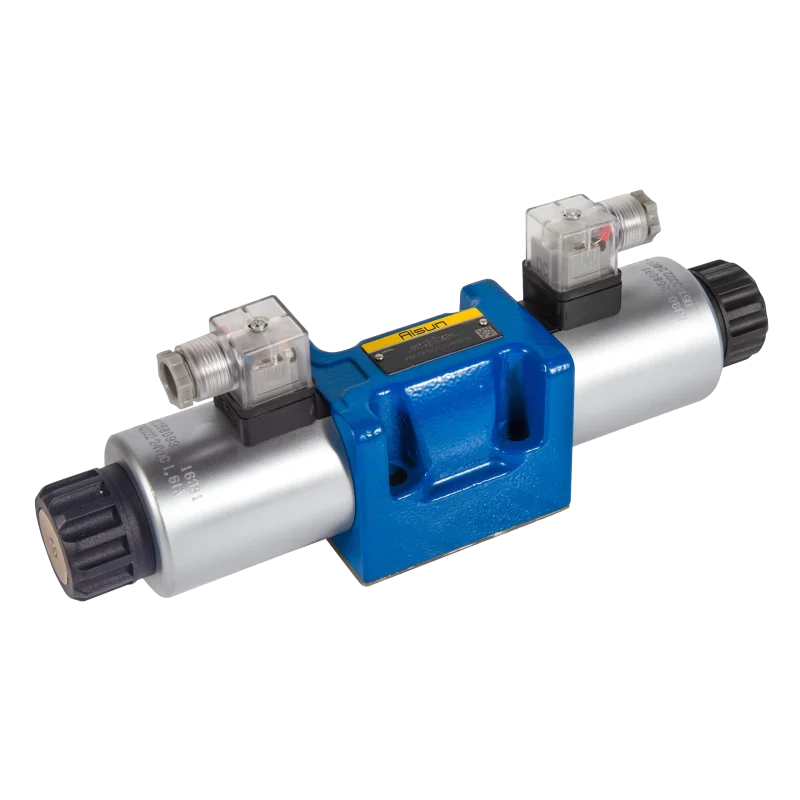

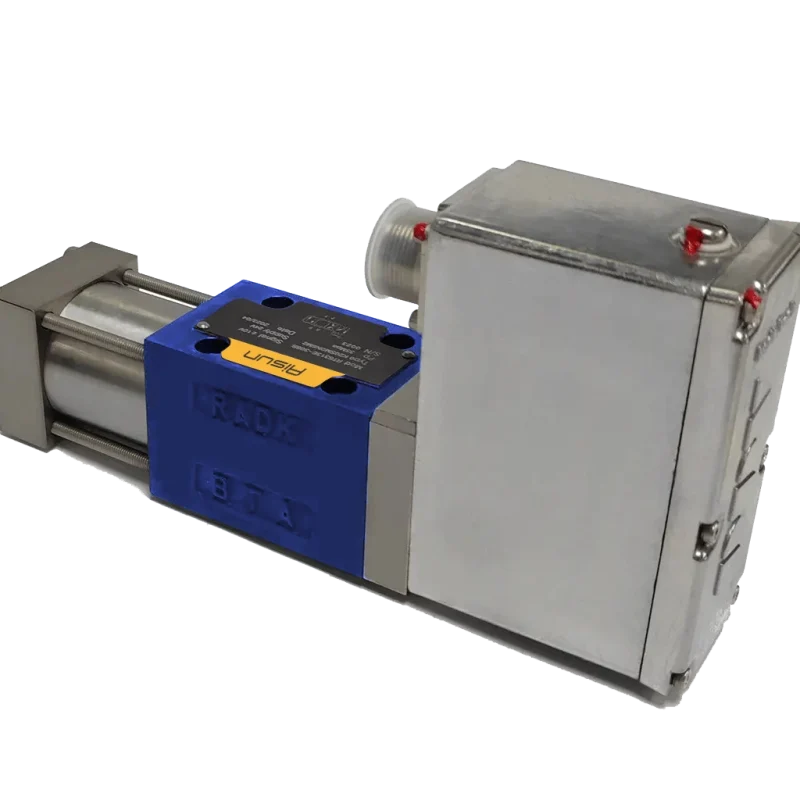

Directional Solenoid Valve 4we

Rated 5.00 out of 5$71 – $124Price range: $71 through $124Directional Solenoid Valve 4we

The 4WE Hydraulic Solenoid Directional Valve is a directional spool valve operated by the solenoid. It controls the opening, closing, and flow direction of the liquid flow. Features:

With the direct type solenoid operated directional spool valve as the standard type

Wet-pin DC or AC solenoids with detachable coil

The solenoid can be rotated by 90°

Replace the coil without releasing the oil

Individual or central electrical connection, optional

Optional manual emergency operation

The control input device of the Hydraulic Solenoid Directional Valve is a switching electromagnet, and the thrust generated when the electromagnet is energized makes the valve core do relative movement in the valve body to realize the reversing. The control signal of the solenoid valve can be directly controlled by the signal sent by the button switch, the stroke switch, the pressure relay and other components, and can also be controlled by the signal sent by the computer, the programmable controller and other control devices, which is convenient and widely used. -

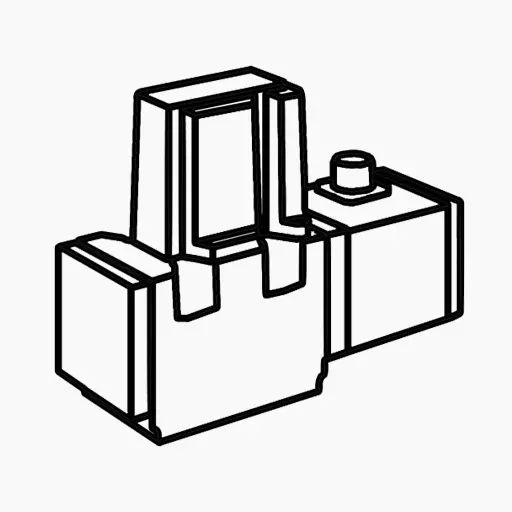

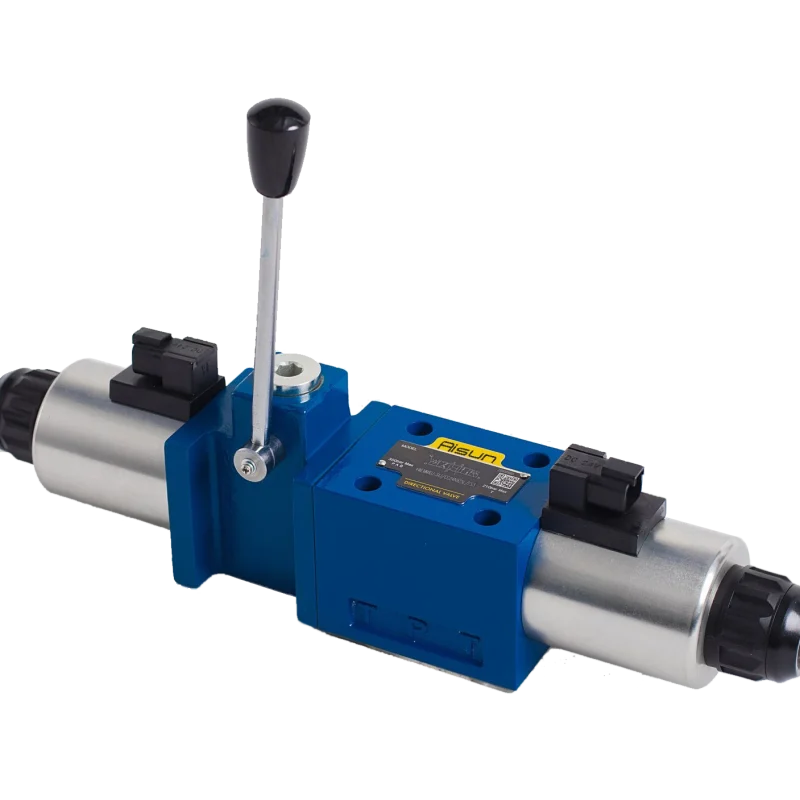

Directional spool valve WMM

Rated 5.00 out of 5$30 – $400Price range: $30 through $400Directional spool valve WMM

In the dynamic world of hydraulic systems, precise control over fluid flow is paramount. The WMM manual valve, specifically the manual directional valve, emerges as a crucial component that allows operators to seamlessly switch oil circuits through manual manipulation. This article aims to delve into the design intricacies, operational mechanisms, and diverse applications of the WMM series, shedding light on its pivotal role in hydraulic engineering.

WMM Manual Valve Overview: The WMM manual valve is a direct-operated directional spool valve designed to facilitate the switching of oil circuits by manually rotating the handle to axially move the spool. This versatile valve comes in 3/2-way, 4/2-way, and 4/3-way configurations, featuring various spool symbols.

The WMM series manual valve is renowned for its robust construction and reliable performance. Its design ensures efficient control over the flow of hydraulic fluids, making it an indispensable component in a wide range of applications. The valve body is made of high-quality materials, such as cast iron or aluminum alloy, which provide excellent durability and resistance to wear and tear. This ensures that the valve can withstand harsh operating conditions and maintain its functionality over a prolonged period.

-

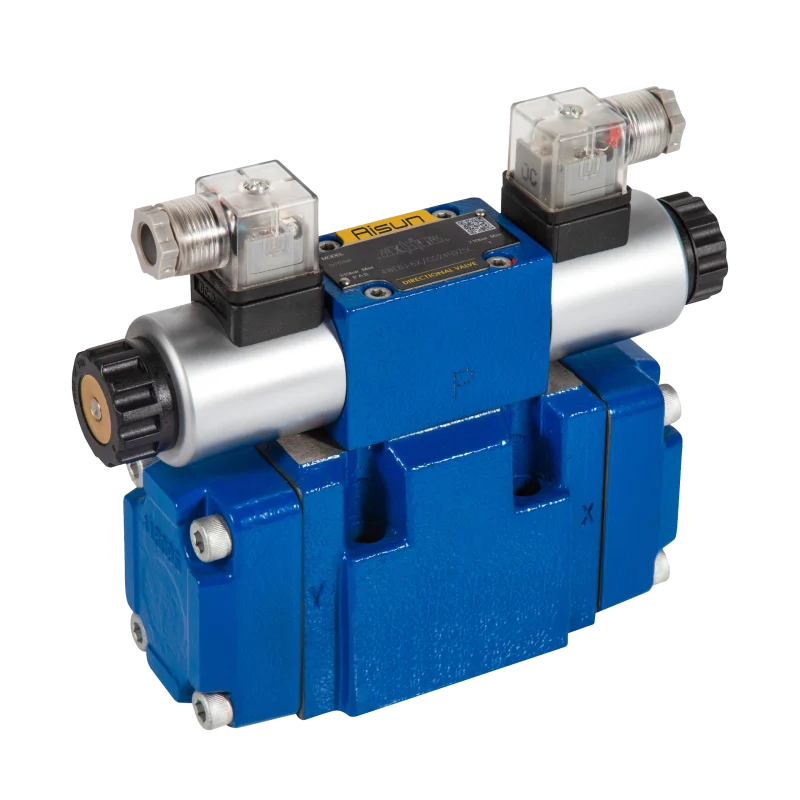

Directional spool valves 4WEMM

Rated 5.00 out of 5$168 – $194Price range: $168 through $194Directional spool valves 4WEMM

Applications in Hydraulic Systems: WEMM type directional spool valves find applications in scenarios where manual actuation is essential, especially during emergencies. The combination of solenoid operation and auxiliary handle control provides flexibility in fluid flow control, catering to diverse hydraulic system requirements.

In conclusion, the WEMM type directional spool valves represent a crucial advancement in hydraulic engineering, offering precise control with both solenoid and manual actuation options. Their versatile design and applications make them indispensable components in hydraulic systems, ensuring reliable performance and emergency response capabilities. As technology continues to evolve, these valves play a vital role in enhancing the efficiency and adaptability of hydraulic systems across various industries. Engineers and practitioners must grasp the intricacies of WEMM type valves to harness their full potential and contribute to the evolving landscape of hydraulic technology.

-

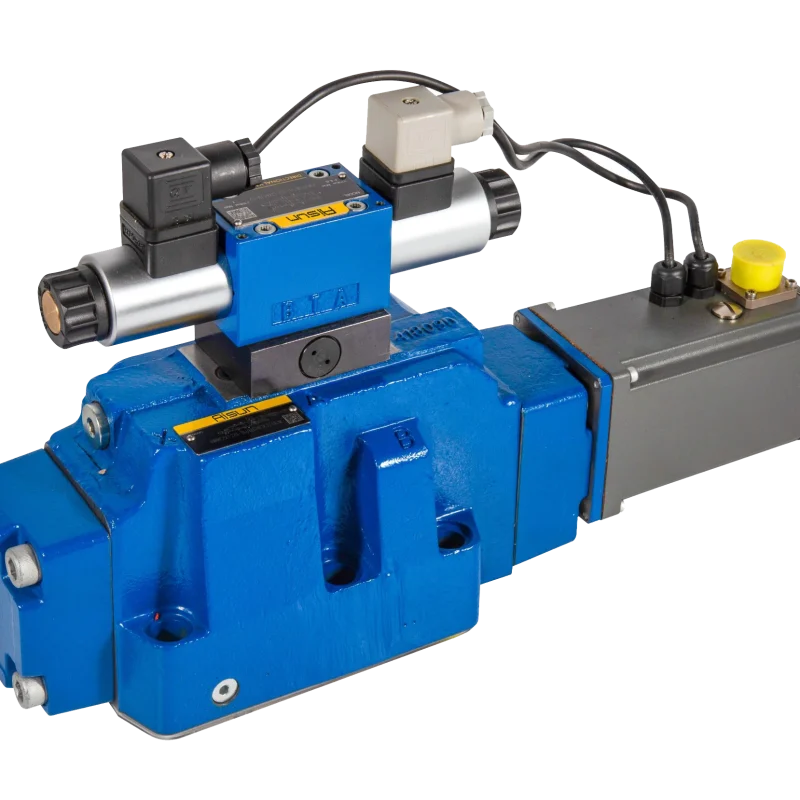

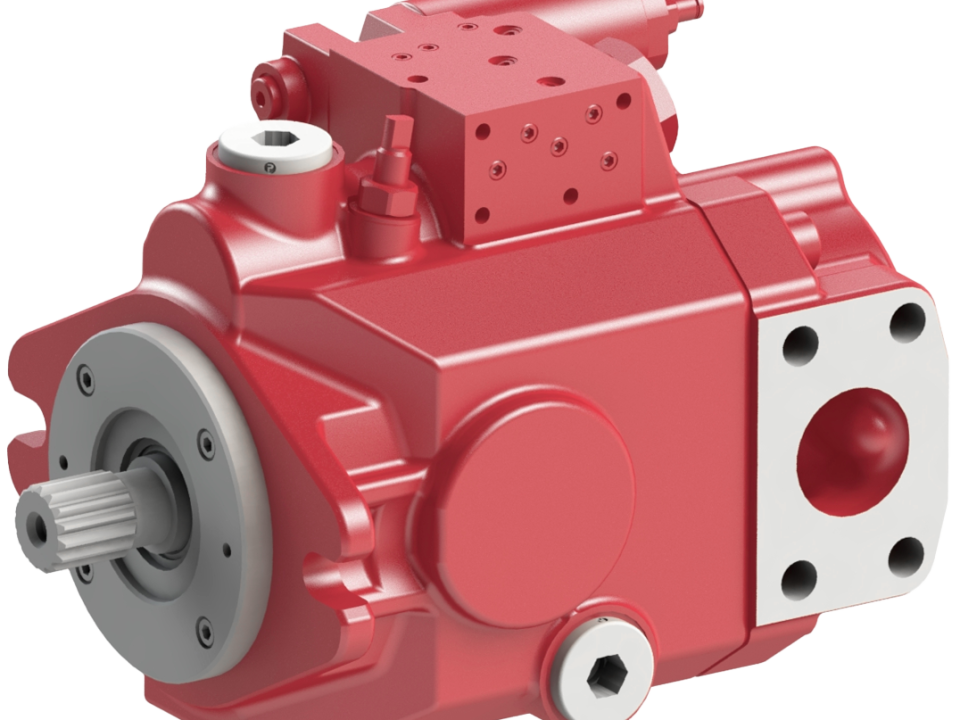

Electro-Hydraulic Directional Valves WEH

Rated 5.00 out of 5$100 – $632Price range: $100 through $632Electro-Hydraulic Directional Valves WEH

WEH Series – Electro-Hydraulic Directional Spool Valve: The WEH series represents a class of directional spool valves featuring Control Valve electro-hydraulic operation. These valves take command of the initiation, cessation, and direction of fluid flow within hydraulic circuits. The core components include the main valve body, main valve spool, one or two return springs, and the pilot valve equipped with one or two solenoids.

Features

- -Control Valve Electro-Hydraulic Operated

- – Valves used to control the start, stop and

- direction of a fluid flow

- – Electro-hydraulic operation (WEH)

- – Hydraulic operation (WH)

- – Subplate mounting

- porting pattern conforms to DIN24340 form A and ISO4401

- – Spring or pressure centered, spring or hydraulic offset

- – Wet pin DC or AC solenoids, optional

- – Hand override, optional

- – Electrical connection as an individual or

- central connection

- – Shifting time adjustment, optional

- – Pre-loading valve in the P-channel of the main valve, optional

- – Auxiliary equipment to data sheet

- – Stroke adjustment at main spool, optional

- – Stroke adjustment and/or end position indicator, optional

- Mechanical or inductive limit switch

- (proximity type) at the main spool

-

Flow Control Valve 2FRM

Rated 5.00 out of 5$103 – $248Price range: $103 through $248Flow Control Valve 2FRM

Hydraulic Valve Flow Control Valve Model: 2FRM

- Size 10 to 16

- Maximum working pressure 315 bar

- Maximum working flflow 160 L/ min

- Optional pressure compensator

- stroke limiter

- Start-up jump reduction

- Lockable knob

- Flow control in both direction by means of current stacking plate

-

Flow control valve DV

Rated 5.00 out of 5$150 – $310Price range: $150 through $310Flow control valve DV

The DV(P)/DRV(P) type flow valves, also known as (Check) Restrictor Valves, are essential flow control valves in hydraulic systems. These valves are specifically designed to regulate the speed of actuators with precision and simplicity. Additionally, they can function as shut-off valves when fully closed, adding to their versatility in hydraulic applications.

The design of the DV(P)/DRV(P) Flow back valves includes a triangular scale that visually represents the flow adjustment. The size of the triangle on the valve scale corresponds to the flow rate, providing a quick and intuitive way to assess the fluid flow magnitude. This visual cue is crucial for operators and system engineers to accurately gauge and control hydraulic flow. -

Flow Control Valve MG & MK

Rated 5.00 out of 5$98 – $123Price range: $98 through $123In the field of hydraulic engineering, precise control over fluid flow is paramount for ensuring optimal performance. The MG and MK valves, as restrictive valves, play a crucial role in achieving this control. With a strong emphasis on oil pressure and viscosity, these valves provide a reliable solution for controlling fluid flow in hydraulic systems. This article will delve into the design intricacies, operational mechanisms, and various applications of the MG and MK valves, highlighting their significance in hydraulic engineering.

Restrictive Valve

The MG model is specifically designed as a restrictive valve capable of throttling fluid flow in both directions. Its design features a side hole (3) through which hydraulic oil passes, reaching the throttling orifice (4). This critical component is formed by the valve body (2) and the adjusting sleeve (1).

Similar to the MG valve, the MK valve is another exemplary restrictive valve utilized in hydraulic systems. It shares a common focus on oil pressure and viscosity, ensuring accurate control over fluid flow. -

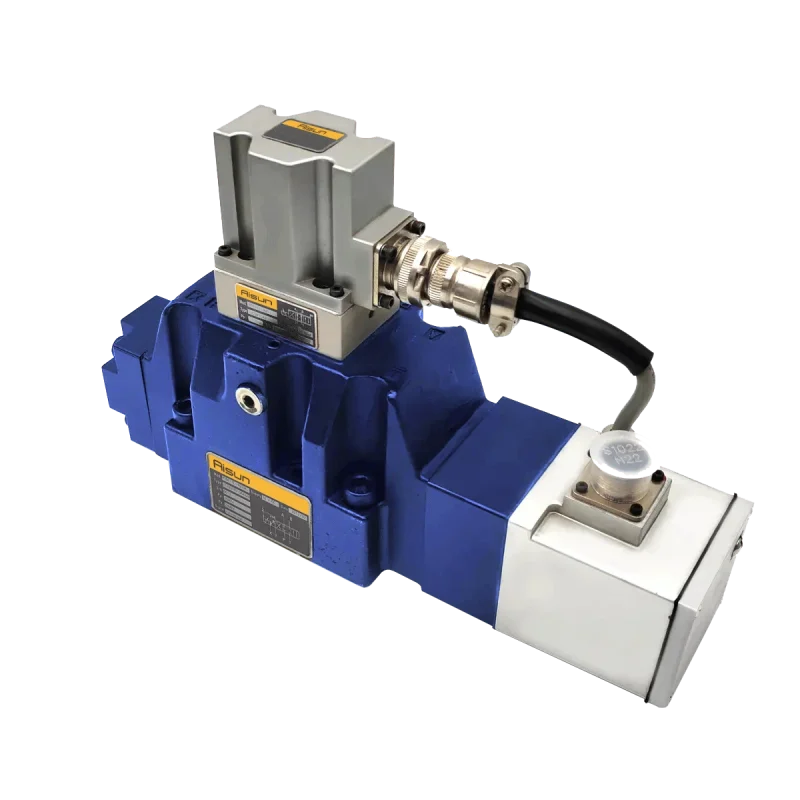

hydraulic Proportional Directional valves 4WRKE

$1.642 – $2.687Price range: $1.642 through $2.687Proportional Directional valves 4WRKE

In the field of fluid power control, the Electro-Hydraulic Proportional Directional Valve (EHPDV) is a critical component that plays a vital role in regulating the flow and direction of hydraulic fluids. Among the various types of EHPDVs available, the 4WRK… stands out as a high-performance, two-stage proportional directional control valve. This valve offers precise control over flow size and direction, making it an ideal choice for applications requiring accurate hydraulic control.

The 4WRKE type proportional directional control valve comprises several key components, including the pilot control valve, housing, main spool, covers, centering spring, inductive position transducer, and pressure reducing valve. Each component serves a specific purpose in ensuring the valve’s smooth operation and precise control over fluid flow. -

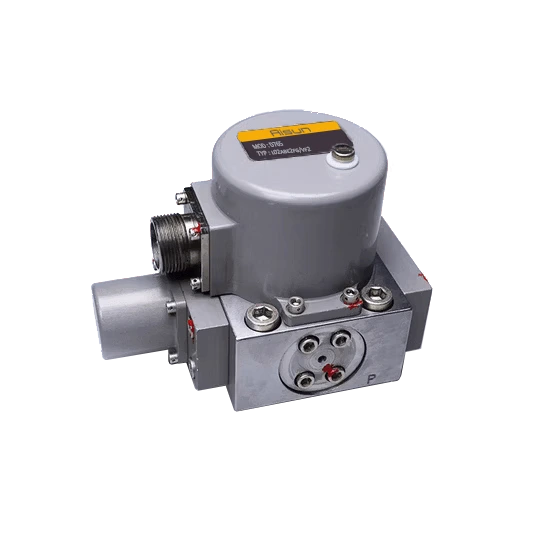

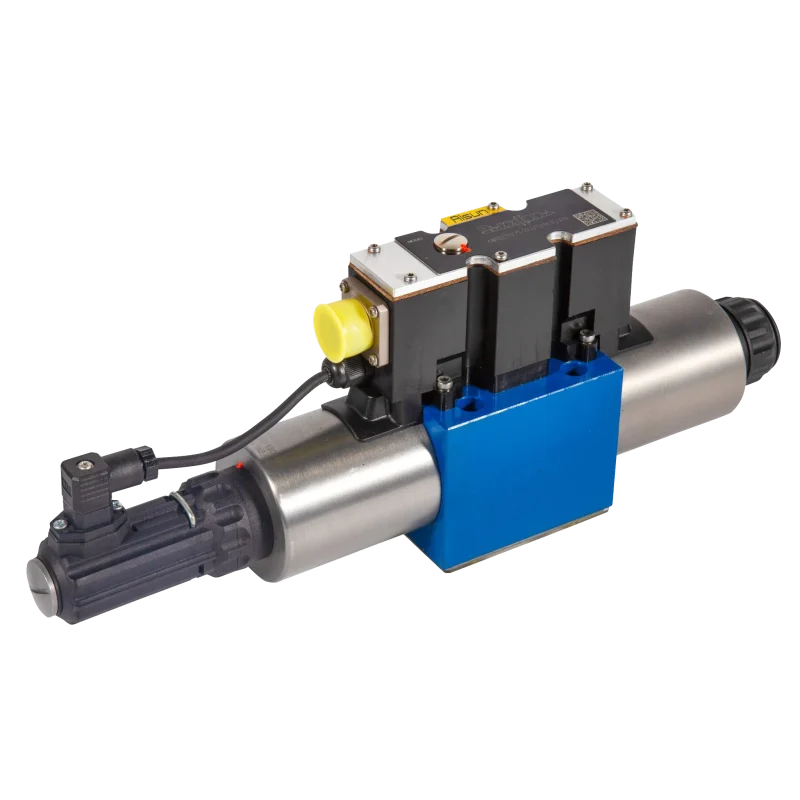

hydraulic Proportional Directional valves 4WRPEH

$1.374 – $1.702Price range: $1.374 through $1.702Proportional Directional valves 4WRPEH

The 4WRPEH high-response Proportional Directional Servo Valve, showcasing the advanced 4WRPEH6 variant, represents a remarkable achievement in fluid control systems. This pilot-operated directional control valve combines cutting-edge technology with precise construction elements to achieve unparalleled operational efficiency.

- Proportional Directional Servo Valve

- With control spool and sleeve in servo quality

- Operated on one side, 4/4-fail-safe position in switched off state

- Electric position feedback and integrated

- electronics(OBE), calibrated in the factory

- Electrical connection 6P+PE signal input differential amplifier with interface’ ‘A1″:土10V or interface’ ‘F1″: 4..20mA (Rsh =2000)

- Subplate mounting

- porting pattern to ISO 4401-03-02

-

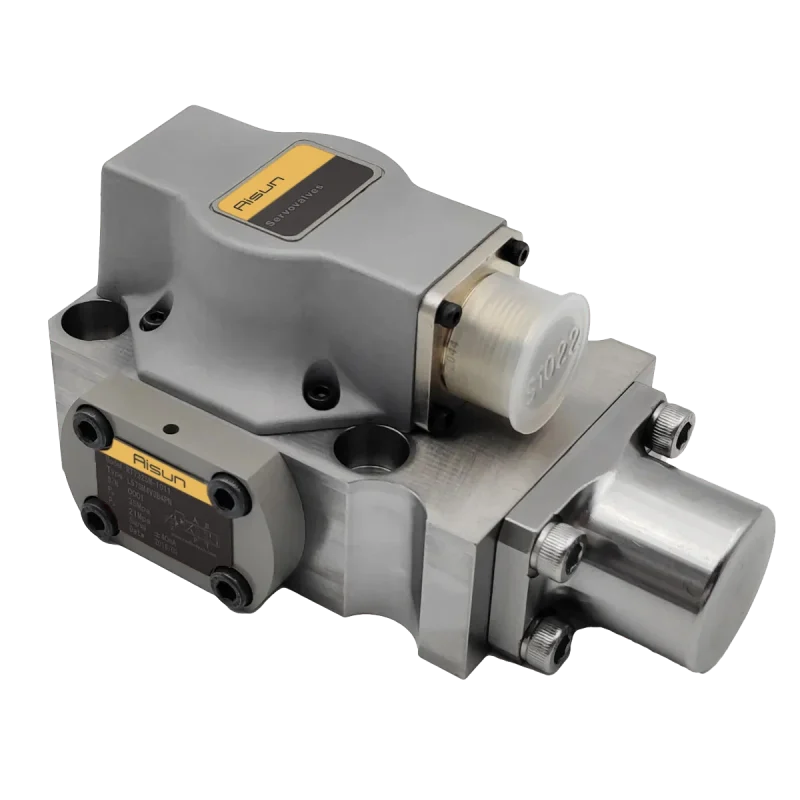

hydraulic Servo Directional valves 730 Series

Servo Directional valves 730 Series

Servo Directional valves 730 Series are a type of high-performance, precision valve used in hydraulic control systems. They are designed to control fluid flow in response to electrical input signals, providing fine, proportional control over hydraulic actuators like cylinders or motors. These valves are essential in applications that require accurate motion or position control, fast response times, and reliable performance in demanding environments. The Servo Directional valves 730 Series are typically used in aerospace, industrial, and other precision-driven applications.

$4.226Original price was: $4.226.$4.141Current price is: $4.141. -

hydraulic Servo Directional valves D660

$5.198 – $9.101Price range: $5.198 through $9.101Servo Directional valves D660

The Servo Directional valves D660 is a type of electro-hydraulic servo valve used in advanced hydraulic control systems. It is designed to offer high precision and high-performance control for regulating fluid flow, pressure, and direction in a wide range of industrial and mobile applications. The D660 series is primarily used in applications where extremely precise control of hydraulic actuators (such as hydraulic cylinders or motors) is critical. These applications can include aerospace, machine tools, automation systems, and high-precision hydraulic testing.

-

hydraulic Servo Directional valves D761

Servo Directional valves D761

The Servo Directional valves D761 is a precision valve commonly used in hydraulic control systems to regulate fluid flow in response to electrical input signals. It is part of the family of servo valves, which are designed to offer high-performance control in applications where precise motion or position control is required. These valves are used in a wide range of industries, including aerospace, industrial automation, robotics, and more.

$3.432Original price was: $3.432.$3.312Current price is: $3.312. -

hydraulic Servo Directional valves D765

Servo Directional valves D765

The Servo Directional valves D765 is a precision valve commonly used in hydraulic control systems to regulate fluid flow in response to electrical input signals. It is part of the family of servo valves, which are designed to offer high-performance control in applications where precise motion or position control is required. These valves are used in a wide range of industries, including aerospace, industrial automation, robotics, and more.

$7.016Original price was: $7.016.$6.903Current price is: $6.903. -

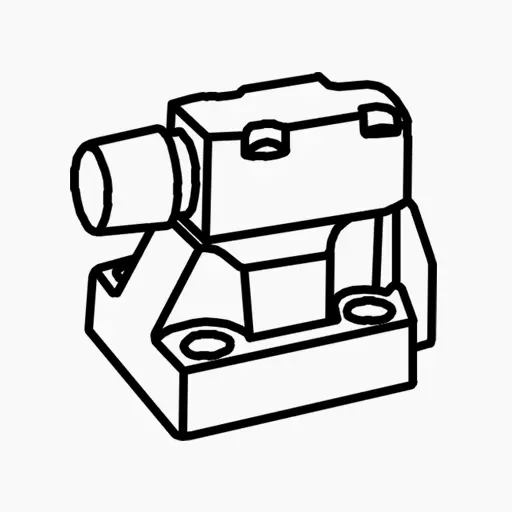

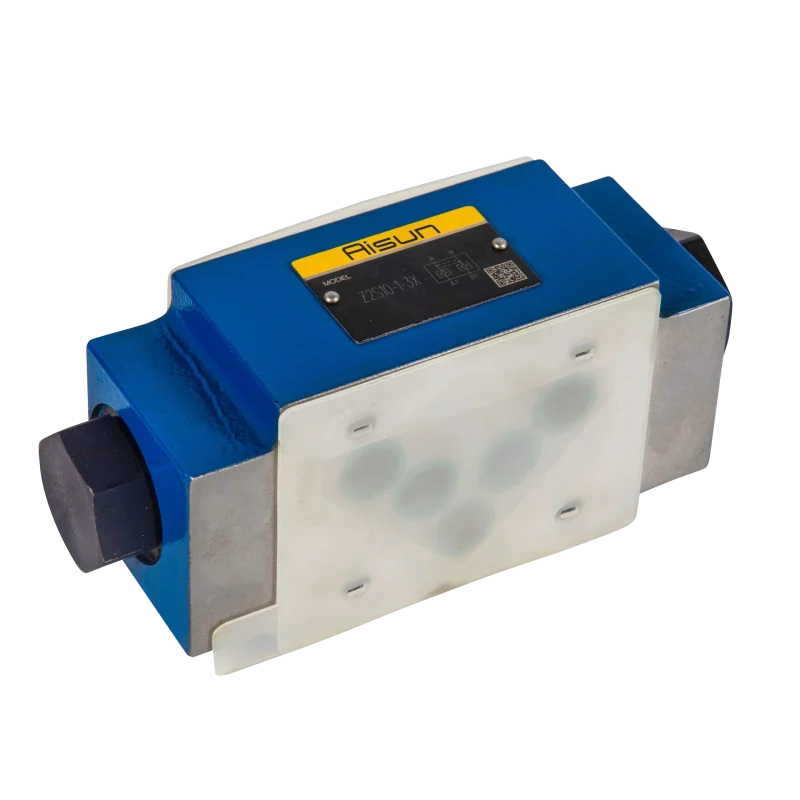

Modular Check Valve Z1S

$48 – $79Price range: $48 through $79Modular Check Valve Z1S

The Z1S type valve is a direct operated check valve with a modular structure. This check valve is closed without leakage in one direction and allows free flflow in the other direction.

The stroke of the conical spool (3) is limited by the spring seat (4). The spring (5) causes the conical spool(3) to close. When there is no flfluid flflows through the valve, the spring (5) holds the conical spool (3) inthe closed position.

Model Z1S10…3XJ/V (metal-sealed) This valve has a metallic seal between the conical spool (3) and the valve body (1). Therefore, it is,particularly suitable for condition of working pressure higher than 100bar and the flflow rate greater than 4m/s.

-

Modular check valve Z2FS

Rated 4.00 out of 5$59 – $348Price range: $59 through $348Modular check valve Z2FS

At its core, the Z2FS check valve operates as a double throttle check valve, boasting a stacked design that sets it apart from conventional counterparts. This design incorporates two throttle check valves symmetrically arranged to govern fluid flow meticulously. The primary objective of this valve is to limit the main flow or control the flow within one or two working oil ports, providing engineers with a versatile tool for managing hydraulic systems with precision.

In scenarios where meter-in control is imperative, the oil fluid follows a specific path from port A1 to A2 through the intricately designed throttle port(1). This port comprises the valve seat (2) and throttle spool (3), components that play a pivotal role in regulating the flow. The adjustability of the throttle spool (3) along its axis, facilitated by the adjusting screw (4), empowers operators to fine-tune throttle port(1) to achieve the desired flow characteristics. Upon the fluid’s return from the working oil port A2, the valve seat (2) opens against the force exerted by the spring (5). This ingenious mechanism transforms the valve into a check valve, allowing for unrestricted free-flow in the opposite direction. The flexibility to configure the valve for meter-in or meter-out control, depending on its installation position, further amplifies its utility in diverse hydraulic applications.

-

Modular Check Valve Z2S

Rated 5.00 out of 5$9 – $232Price range: $9 through $232Modular Check Valve Z2S

In the realm of hydraulic systems, precision control and reliability are paramount. The Z2S type modular hydraulic operated check valve emerges as a pivotal component in this landscape, featuring a sandwich plate design and excelling in providing leakage-free closure for one or two actuator ports, even during extended standstill periods. This article aims to unravel the intricate workings of the Z2S6 valve, shedding light on its design principles, operational mechanisms, and applications within hydraulic systems.

The Z2S6 valve stands as a pilot-operated check valve, ingeniously crafted in a sandwich plate design. Its primary function is to ensure the seamless closure of actuator ports, preventing any undesired fluid flow during prolonged periods of inactivity. The valve allows for unimpeded fluid flow in the A1 to A2 or B1 to B2 direction, and conversely, it efficiently blocks flow in the opposite direction. -

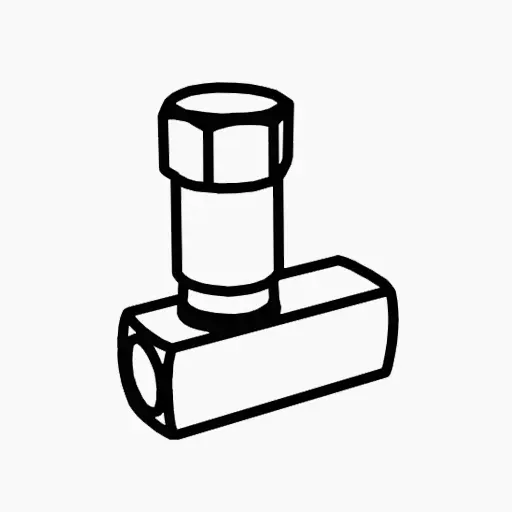

Plug-in check valve M-SR

Rated 3.00 out of 5$80 – $240Price range: $80 through $240Plug-in check valve M-SR

The primary function of a check valve in a hydraulic system is to allow fluid to flow in one direction only while blocking the flow in the opposite direction.

When fluid enters through port p1, the pressure at p1 overcomes the pressure at port p2 acting on the valve core, along with the spring force and friction between the valve core and the valve body, pushing the valve core open and allowing fluid to flow from p1 to p2, achieving forward flow. Conversely, when pressure oil enters from port p2, the valve core is pressed tightly against the valve seat by the combined action of the liquid pressure at p2 and the spring force, blocking the fluid flow and achieving reverse flow cutoff.Features:

- Size 8 to 30

- Maximum working pressure 315 bar

- Maximum working flflow 400 L/min

- Insert into the manifolds blocks

- Reverse closing without leakage

- 6 optional cracking pressure

-

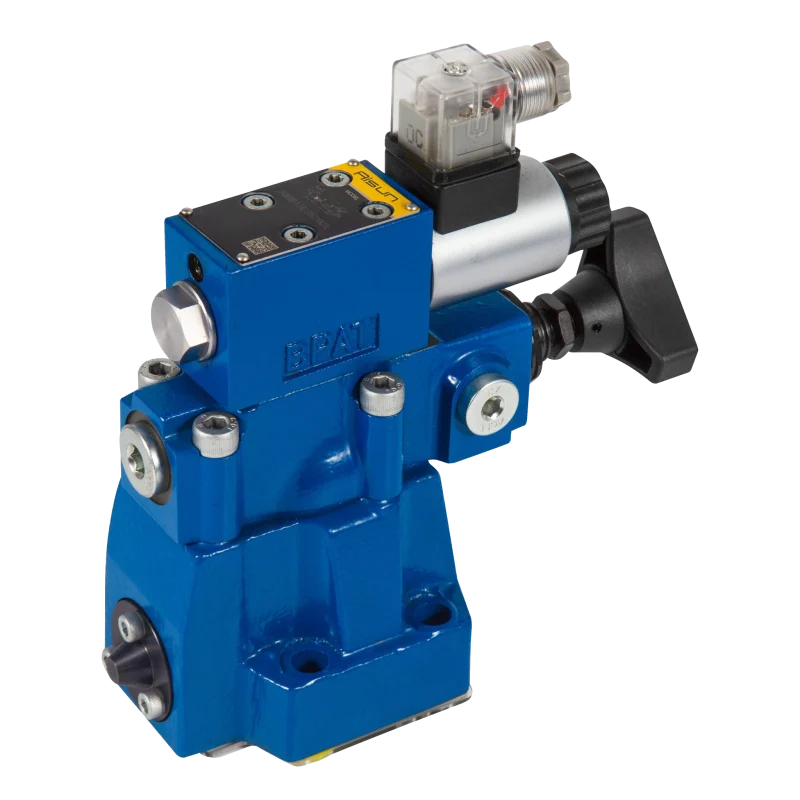

Pressure control valves DB and DBW

Rated 5.00 out of 5$138 – $285Price range: $138 through $285Pressure control valves DB and DBW

The DB and DBW pressure control valves are pilot operated relief valves.

They are used to limit (DB), or to limit and unload by solenoids (DBW) of working pressure.

- ◆ Size 10 to 32

- ◆ Maximum working pressure 350 bar

- ◆ Maximum working flow 650L/min

- ◆Subplate mounting: size 10/20/30

- ◆Threaded connection:size 10/15/20/25/32

- ◆Setting pressure:5MPa/10MPa/20MPa/31.5bar/35MPa

- ◆Flow rate:250L/min (for size 10 only),500L/min (for size 15, 20, 25),650L/min (for size 32 only)

-

Pressure relief valve DBD

$44 – $217Price range: $44 through $217Pressure relief valve DBD

The DBD hydraulic pressure relief valve is direct operated, it is used to limit the pressure of hydraulic system. Features:

- Inserted cartridge

- Threaded connection

- Subplate mounting

- 3 pressure adjustment elements

-Inner hexagon adjusting screw with -protective cap -Adjusting handle -Adjusting handle with lock

The DBD hydraulic pressure relief valve is a crucial component used to regulate and control the pressure in hydraulic systems. Its direct operation ensures efficient and accurate pressure limitation, preventing any potential damage or failure within the system.

-

Proportional directional valves 4WRA

$424 – $1.081Price range: $424 through $1.081Proportional directional valves 4WRA

Proportional directional valves 4WRA are capable of controlling the direction and flow of the hydraulic system according to the polarity and amplitude of the input electrical signal, thus realising the control of the direction and speed of the movement of the actuating elements.

- Size 6 and 10

- Maximum working pressure 315 bar

- Maximum working flflow 42 L/min (size 6)

- 75 L/min (size 10)

- Proportional direction valve with direct operated proportional solenoid

- For subplate mounting

- Control the direction and flow

- Spring centred control spool

- Both valves and proportional amplififiers from the same supplier

-

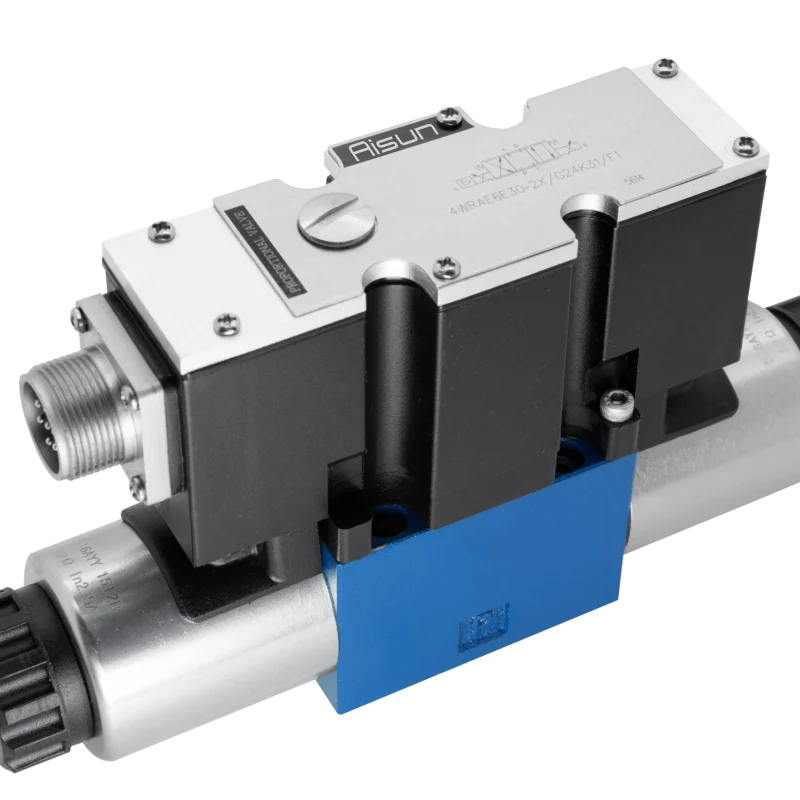

Proportional directional valves 4WRE

$663 – $1.351Price range: $663 through $1.351Proportional directional valves 4WRE

The 4WRE(E) type Proportional Control Valve is a highly advanced and efficient valve used in fluid control systems. It is designed with various components that work together to provide precise and adaptable control.

- Direct operated proportional directional

- valve with electrical position feedback

- Closed loop control of the direction and size of a flow

- Operation is by proportional solenoids with a central thread and removable coil

- For subplate mounting: Porting pattern conforms to ISO 4401

- Spring centred control spool

- Integrated electronics (OBE) with voltage

- input or current input (A1 resp. F1)

- 4WRE separate order: analogue module amplifier

-

Proportional Directional valves D633-D634

$2.761 – $3.312Price range: $2.761 through $3.312Proportional Directional valves D633-D634

The hydraulic servo valves D633 and D634 are typically high-precision components used in hydraulic control systems to manage the flow and direction of hydraulic fluid in applications that require precise movement and control. These valves are a series of hydraulic servo valves and are often used in industries such as aerospace, manufacturing, and heavy machinery.

-

Solenoid Poppet Valve M-SED

Rated 5.00 out of 5$75 – $188Price range: $75 through $188Solenoid Poppet Valve M-SED

The M-SED type valve represents a solenoid actuation directional seat valve, boasting the capability to control the initiation, cessation, and direction of fluid flow. Comprising a valve housing, solenoid, valve seats, and a closing element, this valve is equipped with advanced features that make it an indispensable component in various hydraulic systems.

One of the primary advantages of the M-SED directional Poppet valve is its ability to provide precise and rapid control over fluid flow. This is achieved through the integration of a highly responsive solenoid, which generates a magnetic field to actuate the valve mechanism. The solenoid converts electrical energy into mechanical force, allowing for the precise movement of the valve’s closing element. As a result, the M-SED directional Poppet valve can effectively regulate fluid flow rates, enabling smooth and efficient operation of hydraulic systems.

Furthermore, the M-SED valve exhibits exceptional durability and reliability. Constructed with high-quality materials and designed with meticulous engineering, this valve can withstand harsh operating conditions, including high pressure and temperature environments. Its robust construction ensures long-lasting performance, minimizing downtime and maintenance costs in industrial applications.

The versatility of the M-SED valve is another aspect worth highlighting. With its modular design, this valve can be easily integrated into various hydraulic circuits, offering flexibility in system design and configuration. Additionally, the valve’s compatibility with different fluids makes it suitable for a wide range of applications across diverse industries, including manufacturing, construction, and agriculture.

-

Solenoid Poppet Valve M-SEW

$113 – $186Price range: $113 through $186Solenoid Poppet Valve M-SEW

One of the primary advantages of the M-SEW directional Poppet valve is its ability to provide precise and rapid control over fluid flow. This is achieved through the integration of a highly responsive solenoid, which generates a magnetic field to actuate the valve mechanism. The solenoid converts electrical energy into mechanical force, allowing for the precise movement of the valve’s closing element. As a result, the M-SEW directional Poppet valve can effectively regulate fluid flow rates, enabling smooth and efficient operation of hydraulic systems.

Furthermore, the M-SEW valve exhibits exceptional durability and reliability. Constructed with high-quality materials and designed with meticulous engineering, this valve can withstand harsh operating conditions, including high pressure and temperature environments. Its robust construction ensures long-lasting performance, minimizing downtime and maintenance costs in industrial applications.

Our Advantages

Excellent Quality Assurance

Nearly all the parts are made by ourself, we have more than 600 sets of producing and testing equipments including many kinds of high speed lathes,CNC,high precise grinding machine,testing benches and tesing machines,so we can control the quality very welll.

Fast Delivery Time

We have more than 40 employees and 60 producing and testing equipments,and we have the daily production capacity of 3000 pieces everyday, we we can ensure very fast delivery time.

Quick order

Nearly all the parts are made by ourself, we have more than 100 sets of producing and testing equipments including many kinds of high speed lathes,CNC,high precise grinding machine,testing benches and tesing machines,so we can control the quality very welll.

Join our newsletter.

Receive info about promotions, tutorials and new Products releases.

Brands that are our customers

Our product for you

At the core of our success is a passion for quality. Each valve is meticulously crafted using the latest manufacturing processes and undergoes rigorous testing to guarantee durability and functionality in the most demanding environments. We understand that our customers rely on our products for critical applications, and we are dedicated to providing solutions that exceed their expectations.

aisan Besides, it has a quality tracing system, complete manufacturing techniques, and a scientific, high efficient manufacturing system, which provide a reliable guarantee for the quality of each hydraulic product. The company pays attention to every detail, from manufacturing and logistics delivery to consumption experience

About us

aisan Hydraulics Co. is located in hamedan City Province. It is a hi-tech enterprise focuses on manufacture of hydraulic valves and manifolds as an integration of independent R&D, manufacture, sales, and services.

Based on aisan follows the pace of internationalization and heads towards the world. It adheres to the manufacturing and operation philosophy of “exquisite products, honest conducts, professional dedication, and moral integrity”. As yet, the company has set up sound cooperative partnerships with customers from all over the iran.These products are widely applied to industries such as machine tools, injection machines, agricultural machines, metallurgy industry, vessels, military industry, environmentally-friendly equipment, construction machinery, coal mining machinery, engineering machinery, and aerospace etc.