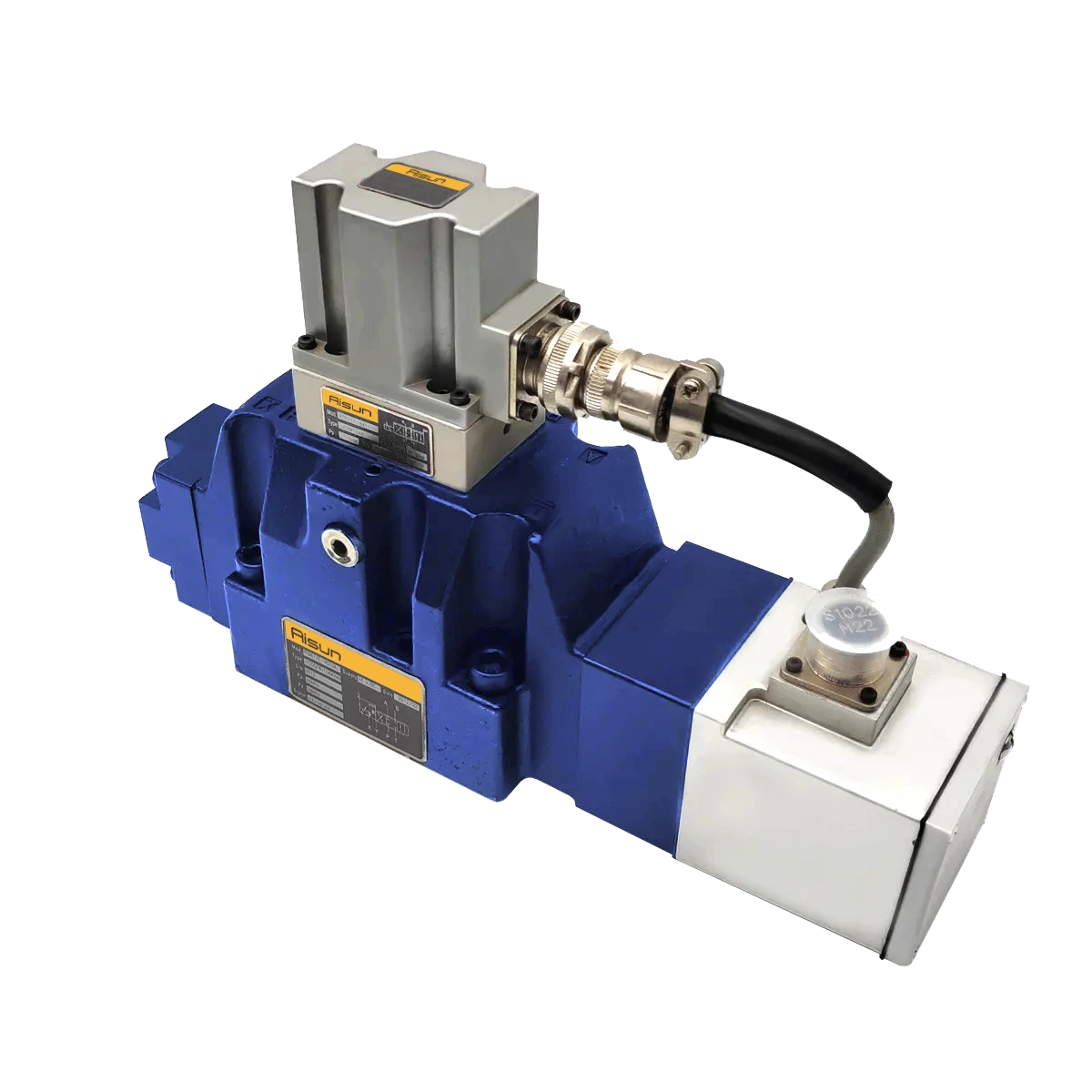

Servo Valve D660 Series

Key Characteristics of the D660 Series Hydraulic Servo Valve

- High-Precision Control:

- The D660 series is specifically designed for high-precision control of fluid flow in hydraulic systems. It can handle fine adjustments in flow rates, pressure, and direction, making it suitable for systems that require fast response and accurate control of hydraulic actuators.

- Servo-Controlled:

- As a servo valve, the D660 series uses feedback control to adjust the position of the valve spool based on the input signal. This allows for precise modulation of the valve’s movement, ensuring that the actuator receives exactly the amount of fluid it needs for specific tasks. Servo valves are typically used in systems that require dynamic response, high-speed operation, and tight control.

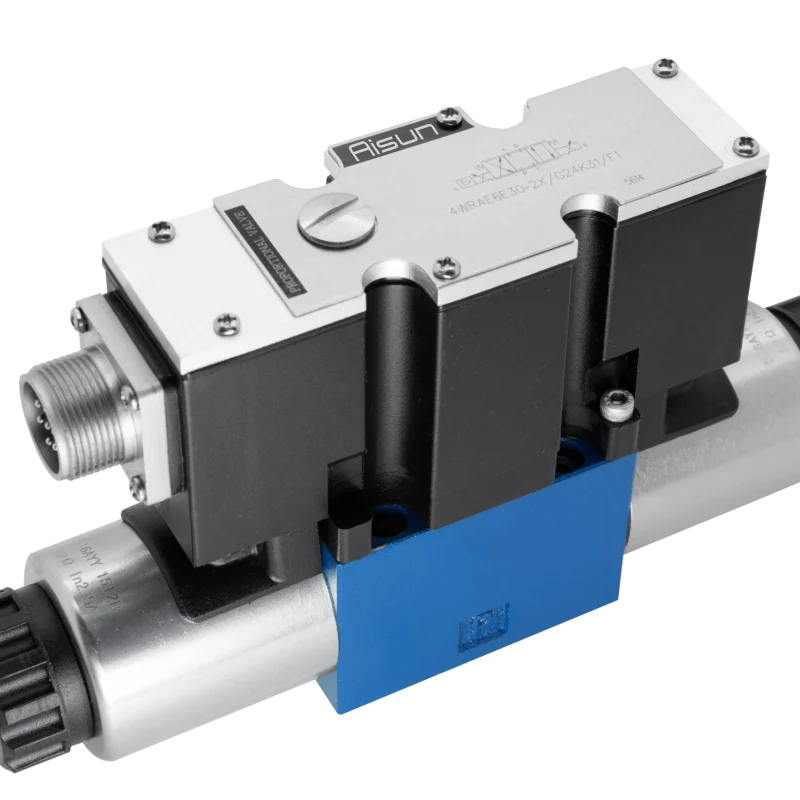

- Electronic Control:

- The D660 series valve is typically operated via an electrical control signal (e.g., 0-10V or 4-20mA). The electrical input is used to position a solenoid or actuator inside the valve, which, in turn, adjusts the position of the valve’s spool. This continuous, proportional control of flow allows for highly dynamic operation.

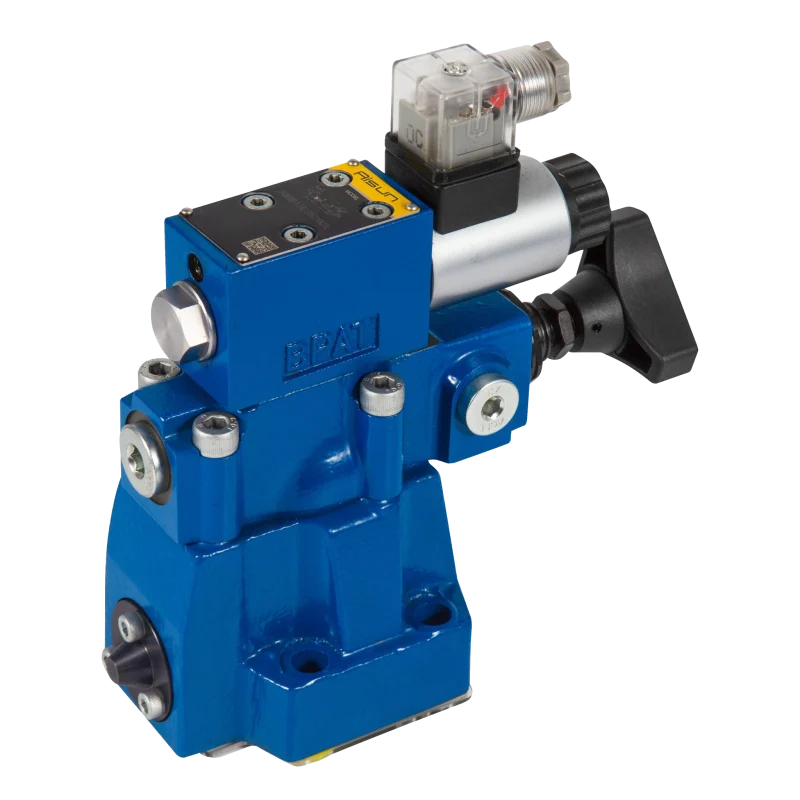

- 4-Way and 3-Position Configuration:

- The D660 series is a 4-way valve with 3 positions. This means it has four ports (P, T, A, and B) and three possible positions for fluid flow:

- Neutral (Center Position): In this position, the valve blocks the flow of hydraulic fluid between the pressure port and workports, isolating the actuator and allowing for standby or idle conditions.

- Position 1: Fluid flows from the pressure port (P) to workport A, while workport B is connected to the tank for return flow.

- Position 2: Fluid flows from the pressure port (P) to workport B, while workport A is connected to the tank.

- The D660 series is a 4-way valve with 3 positions. This means it has four ports (P, T, A, and B) and three possible positions for fluid flow:

- Compact Design:

- The series servo valves are typically compact, which allows them to be integrated into space-limited applications. Their small footprint does not compromise their ability to provide precise control of the hydraulic fluid.

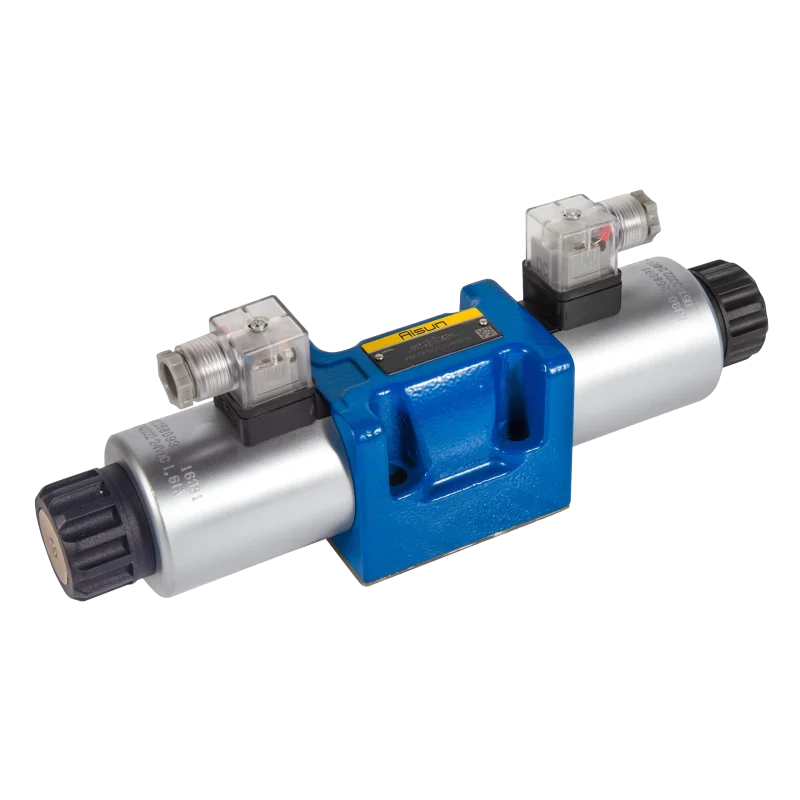

- Closed-Loop Control:

- The series servo valves operate on a closed-loop control system, meaning that they continuously monitor the output (fluid flow, pressure, or position) and adjust the valve’s behavior based on the system’s response. This feedback loop helps ensure accurate positioning and fast response times.

- High Dynamic Performance:

- The series is designed for systems that require fast dynamic responses. This makes it suitable for applications that demand high-speed adjustments to flow and pressure, such as in aerospace actuators, machine tools, and robotic systems.

Working Principle of the D660 Series Hydraulic Servo Valve

- Electrical Control Signal:

- The operation of the D660 series is governed by an electrical signal input (e.g., 0-10V or 4-20mA). This electrical input signal is sent to the valve’s actuator or solenoid, which moves the valve spool. The position of the spool determines the flow rate and direction of the hydraulic fluid.

- Servo Control Mechanism:

- The servo mechanism in the series valve uses feedback to adjust the valve’s behavior. The valve has sensors that measure the position of the valve spool or actuator. This position is then compared to the desired setpoint provided by the input signal.

- If the spool moves off the desired position, the feedback system sends a corrective signal to reposition it, maintaining the desired flow rate or pressure.

- Flow Control:

- The spool position within the series valve modulates the flow of hydraulic fluid to the actuator. When the spool moves, it either allows fluid to flow from the pressure port (P) to the workports (A or B), or it blocks the flow to isolate the actuator. The further the spool moves in response to the input signal, the greater the flow of fluid.

- This proportional control enables the valve to regulate flow smoothly, adjusting the actuator’s movement gradually rather than suddenly.

- Feedback Loop:

- The feedback loop is essential for maintaining the accuracy of the system. As the actuator moves, the system constantly checks the actual position or flow rate, compares it with the target, and makes any necessary adjustments.

- This results in a highly dynamic and accurate response to changing conditions or commands, making the D660 valve ideal for systems requiring fast and precise control.

Applications of the D660 Series Hydraulic Servo Valve

The series hydraulic servo valve is used in high-performance, precision applications where smooth control, high speed, and accuracy are required. Some key applications include:

- Aerospace Systems:

- The valve is commonly used in aerospace for controlling flight control actuators, landing gear systems, and hydraulic systems that require high accuracy and fast response.

- Machine Tools:

- In machine tools, such as CNC machines, the series valve controls hydraulic cylinders or other actuators that drive cutting, positioning, and shaping operations. It enables high-precision movements needed for machining operations.

- Industrial Automation:

- The valve is used in robotics and automated systems where precision control is necessary. It ensures that hydraulic actuators move exactly as required for tasks such as assembly, welding, and material handling.

- Testing Equipment:

- In hydraulic test systems, the series valve is used to create controlled conditions for testing hydraulic components. Its precise control helps ensure the components are tested under accurate and repeatable conditions.

- Marine and Offshore Equipment:

- The D660 valve is also used in marine and offshore applications, such as controlling cranes, winches, and steering systems where precise hydraulic control is required for handling heavy loads.

- Robotics:

- In robotic systems, the valve enables smooth and precise movement of hydraulic actuators, allowing for accurate positioning and motion control in robotic arms and automated assembly lines.

Advantages of the D660 Series Hydraulic Servo Valve

- High Precision and Accuracy:

- The D660 series is designed to offer exceptional precision, allowing it to control hydraulic actuators with very fine adjustments. This level of accuracy is critical in applications where the smallest variation in flow can affect performance.

- High Dynamic Performance:

- The valve offers high dynamic performance, responding quickly to changes in input signals and providing fast adjustments to flow and pressure. This is especially beneficial for systems that require rapid response times.

- Closed-Loop Feedback Control:

- The use of a closed-loop feedback system ensures that the valve’s performance is consistently aligned with the desired target, maintaining accurate control of fluid flow and actuator movement.

- Compact and Robust:

- The D660 series valve is typically compact, allowing it to be used in space-constrained applications. Despite its small size, it is robust and capable of handling high-pressure systems.

- Versatility:

- The servo valve is versatile and can be integrated into a variety of systems, from aerospace to industrial automation, providing precise hydraulic control across multiple industries.

hydraulic Servo Directional valves D660

Servo Directional valves D660

The Servo Directional valves D660 is a type of electro-hydraulic servo valve used in advanced hydraulic control systems. It is designed to offer high precision and high-performance control for regulating fluid flow, pressure, and direction in a wide range of industrial and mobile applications. The D660 series is primarily used in applications where extremely precise control of hydraulic actuators (such as hydraulic cylinders or motors) is critical. These applications can include aerospace, machine tools, automation systems, and high-precision hydraulic testing.