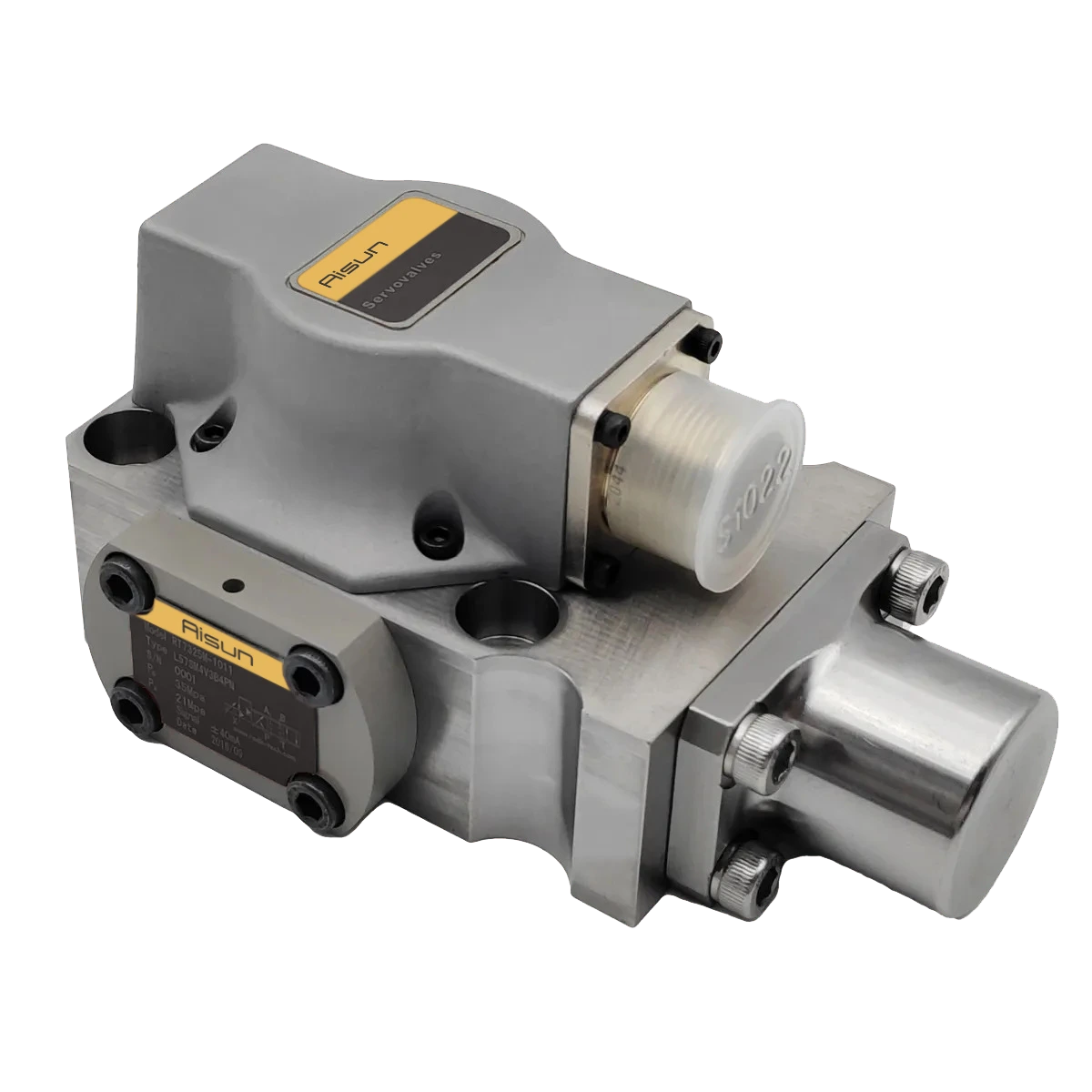

Servo Valve D730

Features of the Servo Directional valves 730 Series:

1. Proportional Control:

• The 730 Series valves are proportional in nature, meaning that the flow of hydraulic fluid is directly proportional to the electrical input signal. This input could be a current or voltage, depending on the system’s configuration.

• The flow and pressure are adjusted smoothly in real-time, which makes these valves ideal for applications that require fine, continuous control, such as in hydraulic actuators, steering systems, or robotics.

2. High Precision and Accuracy:

• The 730 Series valves are engineered for high precision control. They provide excellent flow accuracy with minimal hysteresis (i.e., the lag between input changes and output response), ensuring that even small adjustments in the input signal result in precise changes in flow.

• This makes them ideal for applications where small variations in position, speed, or force have significant impacts, such as in aerospace control systems or fine-motion robotics.

3. Fast Response Time:

• These servo valves are designed to have fast dynamic response to input signals. This is important for systems that need to react quickly to changes in conditions or loads, ensuring that the actuator reaches its desired position or speed without delay.

• Their fast response is critical in applications such as flight control systems, robotics, or industrial automation, where real-time adjustments are necessary for performance and safety.

4. Two-Stage Design:

• The 730 Series often features a two-stage design. In this configuration, the first stage is a precision control stage, where the flow is finely metered based on the input signal. The second stage is a power stage that handles higher flow rates required for actuating the hydraulic system.

• This combination ensures that the valve can maintain fine control while delivering the high flow needed for large hydraulic actuators.

5. Closed-Loop Feedback:

• Many valves in the 730 Series are equipped with feedback systems that monitor the position of the valve spool or actuator. This feedback allows the system to continuously adjust and correct the valve’s operation, ensuring that the output flow remains consistent with the input signal.

• The feedback loop provides closed-loop control, which enhances accuracy and stability by compensating for changes in load, pressure, or system dynamics.

6. High Flow and Pressure Capability:

• The 730 Series valves are capable of handling high flow rates and high pressures, which makes them suitable for large-scale industrial or aerospace applications.

• They are engineered to perform reliably even under extreme conditions, ensuring consistent operation in systems that demand both power and precision.

7. Durability and Reliability:

• These valves are built to withstand demanding operating environments. They are designed to be robust and durable, ensuring long service life and consistent performance even in high-pressure, high-flow, or harsh conditions.

• The 730 Series valves often feature materials and designs that reduce wear and tear, providing extended operational longevity.

8. Application Areas:

• Aerospace: These valves are widely used in flight control systems, where they provide precise control of hydraulic actuators for wing surfaces, landing gear, and other critical systems.

• Industrial Automation: The 730 Series can be used in CNC machines, test rigs, and other industrial applications requiring precise motion control, such as position, speed, or force regulation.

• Robotics: For robots that require precise and reliable motion control, the 730 Series is an ideal choice, offering smooth, continuous, and fast adjustments in hydraulic systems.

• Defense: Military applications often require precise, high-pressure hydraulic control for various systems such as gun turrets, hydraulic weapons, or vehicles.

9. Advanced Control:

• The 730 Series can be integrated with advanced control systems that enable digital or analog signal processing for even more fine-tuned control over the actuator’s behavior.

• This makes the valves suitable for applications that require complex, multi-axis control or simultaneous regulation of multiple actuators.

Advantages of the Servo Directional valves 730 Series Hydraulic Servo Valves:

• High Precision: These valves offer outstanding precision in regulating fluid flow, which is critical for applications such as aerospace and robotics.

• Fast and Dynamic Response: The fast response times make them well-suited for applications with changing load or control conditions.

• Robust Performance: The valves are designed for high flow and pressure applications, making them reliable in harsh environments.

• Closed-Loop Control: The feedback mechanism ensures accurate and stable operation even under dynamic load conditions.

• Versatility: The Servo Directional valves 730 Series is adaptable to a wide range of industries and applications, from precision robotics to aerospace systems.

hydraulic Servo Directional valves 730 Series

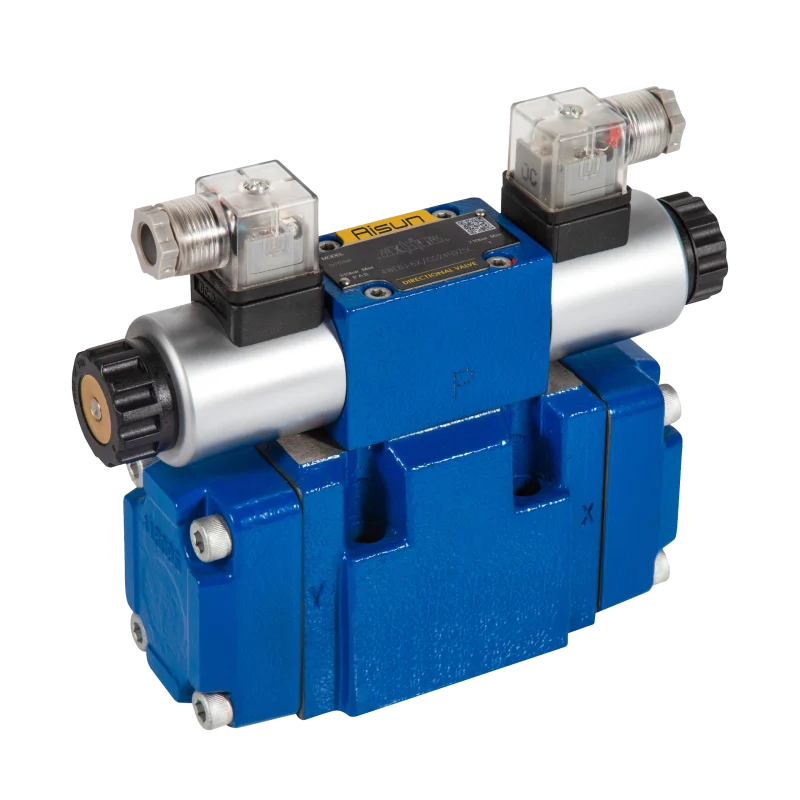

Servo Directional valves 730 Series

Servo Directional valves 730 Series are a type of high-performance, precision valve used in hydraulic control systems. They are designed to control fluid flow in response to electrical input signals, providing fine, proportional control over hydraulic actuators like cylinders or motors. These valves are essential in applications that require accurate motion or position control, fast response times, and reliable performance in demanding environments. The Servo Directional valves 730 Series are typically used in aerospace, industrial, and other precision-driven applications.