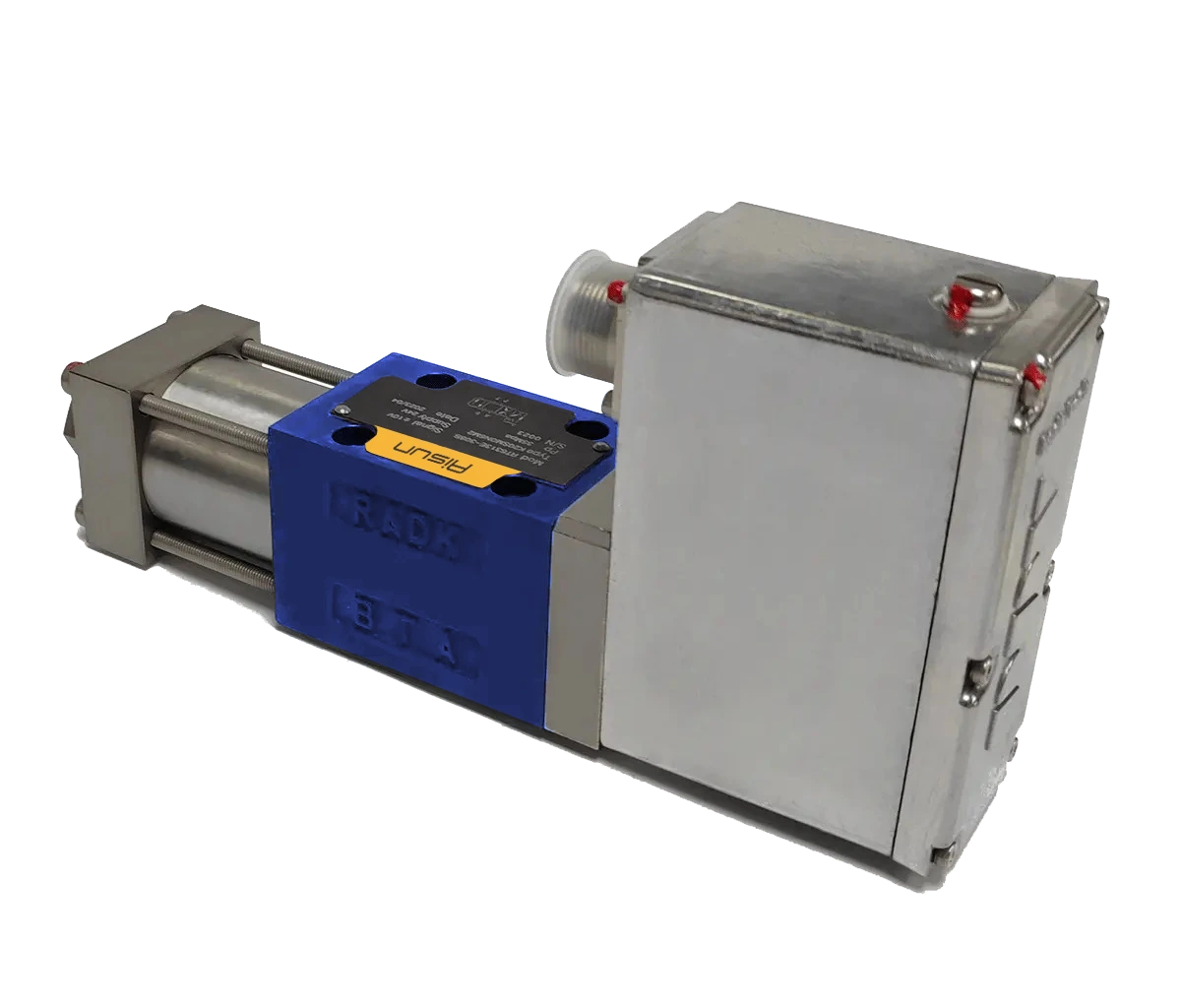

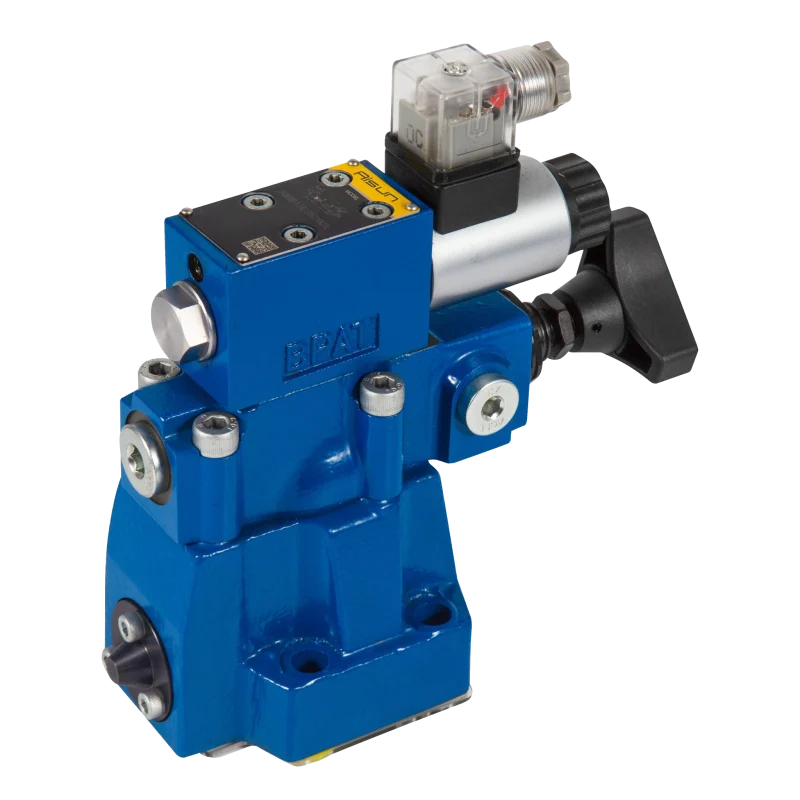

Servo-proportional Valve D633 & D634

detailed explanation of these valves:

1. General Function

Hydraulic servo valves are used to control the movement of hydraulic actuators (such as cylinders and motors) by regulating the hydraulic fluid flow to them. They are critical for ensuring the precise positioning and speed control of these actuators, especially in systems requiring fine-tuned adjustments and high-speed operations.

The valves are particularly designed for high-performance applications where precision, reliability, and stability are key.

2. Working Principle

These valves operate based on electrohydraulic control. The input signal (usually an electrical signal) controls the movement of a spool within the valve. The spool movement alters the flow rate and direction of the hydraulic fluid, thereby controlling the hydraulic actuator’s position, speed, and force.

The key components involved in the operation of these valves include:

– Electromagnetic coils: These coils generate a magnetic field when an electrical signal is applied, which moves the armature or spool.

– Spool: The spool is the key mechanical part that modulates the fluid flow through the valve ports based on the signal received.

– Feedback mechanisms: Often, there are position sensors (e.g., linear variable differential transformers or LVDTs) to ensure that the valve responds correctly to the control signal and adjusts the flow precisely.

3. Specific Features

While these two models are similar in many aspects, they may differ in terms of specific characteristics or applications. Some general features for these valves include:

– High precision control: Both valves are known for their excellent control over flow rate, making them suitable for fine-tuned operations.

– High response time: These valves are designed for systems that require quick responses to changes in input signals, often found in applications such as aerospace actuators and high-precision industrial machines.

– Pressure ratings: These valves are typically rated for high-pressure hydraulic systems, ensuring that they can handle the demanding conditions found in heavy-duty industrial and aerospace environments.

– Compensation: These valves feature a compensation mechanism to minimize the effects of external disturbances, ensuring the flow remains steady despite variations in pressure or temperature.

– Dual stage control: Some models (like the D633 and D634) feature a dual-stage control mechanism that enhances both stability and precision in controlling the actuator movements.

4. Applications

The valves are typically used in applications such as:

– Aerospace: In aircraft flight control systems for managing precise control surfaces and actuators.

– Robotics: For controlling hydraulic actuators that require exact movement in robotic arms or other machinery.

– Industrial machinery: Used in CNC (Computer Numerical Control) machines, injection molding machines, and other machinery that requires precise hydraulic control.

– Automated production systems: Where accurate and fast hydraulic adjustments are needed.

5. Advantages

– High control precision: Ideal for applications needing exact control of motion and force.

– Reliability: Designed to work reliably under high pressure and demanding conditions.

– Flexibility: Can be used in various systems across different industries, including aerospace and manufacturing.

6. Potential Drawbacks

– Complexity: These valves require careful calibration and setup, which may demand expertise.

– Cost: Due to their precision and high performance, they tend to be more expensive compared to simpler hydraulic control valves.

– Maintenance: Regular maintenance and proper system design are required to ensure consistent performance over time, especially in demanding applications.

In summary, the D633 and D634 hydraulic servo valves are specialized components designed for high-performance applications that require precise hydraulic control. Their ability to quickly and accurately modulate fluid flow makes them crucial in industries where fine control over motion is essential.

Proportional Directional valves D633-D634

Proportional Directional valves D633-D634

The hydraulic servo valves D633 and D634 are typically high-precision components used in hydraulic control systems to manage the flow and direction of hydraulic fluid in applications that require precise movement and control. These valves are a series of hydraulic servo valves and are often used in industries such as aerospace, manufacturing, and heavy machinery.