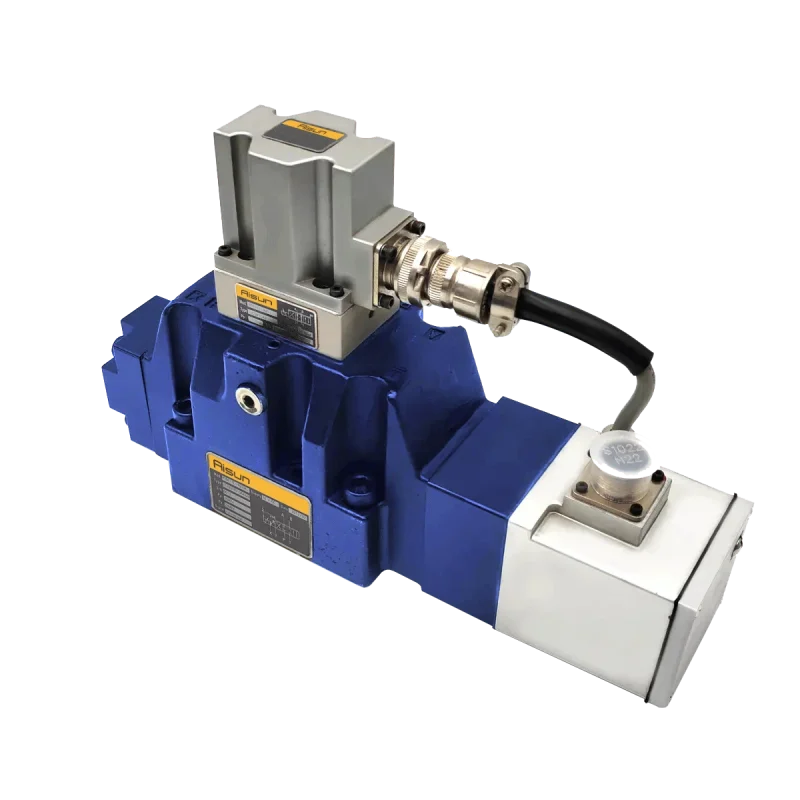

Proportional Directional Control Valve 4WRPEH

A 4WRPEH hydraulic valve is a type of proportional directional control valve used in hydraulic systems for precise control of fluid flow and direction. The 4WRPEH is part of the family of electro-hydraulic proportional valves, and like other proportional valves, it modulates flow based on an electrical input signal. The 4WRPEH valve is particularly known for its ability to provide both proportional control and directional control with high precision in applications such as mobile machinery, industrial automation, robotics, and hydraulic systems.

Key Characteristics of the 4WRPEH Hydraulic Proportional Valve

- 4-Way Valve:

- The 4WRPEH is a 4-way valve, meaning it has four ports for fluid entry and exit:

- P (Pressure): The inlet port where pressurized hydraulic fluid enters the valve from the hydraulic pump.

- T (Tank): The return port where fluid exits the valve and is directed back to the tank or reservoir.

- A and B (Workports): These ports connect to the hydraulic actuator (e.g., hydraulic cylinders or motors). The flow can be directed to either of these ports depending on the valve’s position.

- The 4WRPEH is a 4-way valve, meaning it has four ports for fluid entry and exit:

- 3-Position Design:

- The 4WRPEH valve typically features a 3-position design, meaning it can hold three distinct spool positions:

- Neutral (Center Position): In this position, the valve blocks the flow between the pressure and workports, isolating the actuator and allowing for standby or idle conditions.

- Position 1: Fluid flows from the pressure port (P) to workport A, while workport B is connected to the tank for return flow.

- Position 2: Fluid flows from the pressure port (P) to workport B, while workport A is connected to the tank for return flow.

- The positions correspond to different flow paths for the hydraulic fluid depending on the actuator’s desired direction and operation.

- The 4WRPEH valve typically features a 3-position design, meaning it can hold three distinct spool positions:

- Proportional Control:

- The 4WRPEH valve is proportional, meaning the flow rate through the valve can be continuously adjusted based on the input signal. This allows for precise modulation of flow to the actuator (e.g., hydraulic cylinders or motors) rather than simple on/off operation.

- Proportional control is achieved via an electro-hydraulic actuator, which moves the valve spool based on an electrical input signal. This means that the flow of fluid can be adjusted incrementally, providing better control over actuator speed, force, and position.

- Electro-Hydraulic Actuation:

- The valve is operated by an electro-hydraulic actuator, which uses an electromagnetic solenoid to control the movement of the valve spool. The solenoid is driven by an electrical signal, usually 4-20mA or 0-10V, which directly determines the valve spool’s position and hence the flow rate.

- As the electrical signal increases, the solenoid moves the spool to allow more fluid to pass through to the actuator. Conversely, a lower signal results in less movement and restricted fluid flow.

Working Principle of the 4WRPEH Hydraulic Proportional Valve

- Electrical Input Signal:

- The control signal (e.g., 4-20mA, 0-10V, etc.) is sent to the solenoid, controlling the valve’s movement. This signal can come from a variety of control sources, including PLCs (Programmable Logic Controllers), joystick controllers, or automatic control systems.

- Valve Spool Movement:

- The electrical signal causes the solenoid to move, which in turn adjusts the position of the valve spool. The spool’s position regulates the amount of fluid flowing through the valve and the direction in which it flows.

- As the solenoid moves the spool, the valve either opens or closes the paths between the pressure port (P) and the workports (A and B), allowing fluid to flow to the actuator in a controlled manner.

- Flow Control:

- The proportional valve’s key feature is its ability to adjust the flow rate based on the signal. The spool’s movement is continuous, meaning the flow can vary incrementally instead of being fixed at one or two discrete flow levels (as in on/off valves).

- This continuous modulation allows for smooth and precise control of actuator speed and position, avoiding the jerky motion that might occur with simple on/off valves.

- Neutral Position:

- In the neutral position, the valve prevents flow between the pressure port and workports, effectively isolating the actuator and sending the excess fluid to the tank or reservoir.

Applications of the 4WRPEH Proportional Valve

The 4WRPEH proportional valve is used in various industries where precise control over hydraulic actuators is required, including:

- Mobile Machinery:

- In construction equipment, agricultural machinery, forklifts, and material handling equipment, the 4WRPEH valve provides precise control over hydraulic cylinders and motors, allowing for smooth and efficient operation of the machine.

- Industrial Automation:

- The valve is commonly used in industrial automation systems to control hydraulic presses, robotic arms, material handling systems, and other automated machinery requiring accurate hydraulic control.

- CNC Machines:

- The 4WRPEH valve is used in CNC (Computer Numerical Control) machines to control the movement of hydraulic actuators with great precision, ensuring accurate positioning and motion in machining, cutting, and milling processes.

- Robotics and Automation:

- In robotic arms or automated assembly lines, the 4WRPEH valve helps ensure that the actuators controlling movement are precisely modulated for tasks such as welding, assembly, or handling.

- Hydraulic Test Systems:

- Test systems for hydraulic components can use the 4WRPEH valve to maintain precise control over pressure and flow during testing, providing repeatable and accurate results.

- Marine and Offshore Equipment:

- In marine hydraulic systems (e.g., cranes, winches, and steering systems), the 4WRPEH valve can provide reliable control for demanding, precision-based applications in harsh environments.

Advantages of the 4WRPEH Hydraulic Proportional Valve

- High Precision:

- The proportional nature of the valve allows for high-precision control of actuator speed, force, and position. This is essential for applications requiring fine adjustments, such as in robotics, CNC machines, and mobile equipment.

- Smooth Operation:

- The ability to gradually vary the flow rate leads to smooth actuator movement, avoiding jerky motion and reducing mechanical wear on the system.

- Energy Efficiency:

- Proportional valves allow the system to provide only the necessary amount of hydraulic power for the task, leading to more energy-efficient operation compared to full-flow, on/off valves.

- Flexible Integration:

- The valve can be easily integrated into various control systems, such as PLCs, joystick controllers, or automatic control systems, giving operators flexibility in managing hydraulic actuators.

- Reduced Shock Loads:

- The continuous flow adjustment helps prevent shock loads or sudden pressure surges, improving the longevity and reliability of the hydraulic system.

Summary of the 4WRPEH Hydraulic Proportional Valve

- The 4WRPEH is a 4-way, 3-position proportional directional control valve designed to control the flow and direction of hydraulic fluid with precise modulation based on an electrical input signal.

- It is ideal for applications requiring smooth, controlled movement of hydraulic actuators, such as in mobile machinery, industrial automation, robotics, and hydraulic test systems.

- The valve offers advantages such as high precision, energy efficiency, flexible integration, and smooth operation, making it suitable for a wide range of hydraulic systems where fine control of fluid flow is essential.

Applications:

- Mobile equipment, CNC machines, robotics, industrial presses, and marine equipment all benefit from the precision and efficiency offered by the 4WRPEH hydraulic proportional valve.

hydraulic Proportional Directional valves 4WRPEH

Proportional Directional valves 4WRPEH

The 4WRPEH high-response Proportional Directional Servo Valve, showcasing the advanced 4WRPEH6 variant, represents a remarkable achievement in fluid control systems. This pilot-operated directional control valve combines cutting-edge technology with precise construction elements to achieve unparalleled operational efficiency.

- Proportional Directional Servo Valve

- With control spool and sleeve in servo quality

- Operated on one side, 4/4-fail-safe position in switched off state

- Electric position feedback and integrated

- electronics(OBE), calibrated in the factory

- Electrical connection 6P+PE signal input differential amplifier with interface’ ‘A1″:土10V or interface’ ‘F1″: 4..20mA (Rsh =2000)

- Subplate mounting

- porting pattern to ISO 4401-03-02