Proportional Directional Control Valve 4WRKE

The 4WRKE hydraulic valve is a type of proportional directional control valve that is widely used in hydraulic systems for precise and continuous control of fluid flow, direction, and pressure. It is part of a family of electro-hydraulic proportional valves, and its primary function is to provide proportional control over hydraulic actuators like motors and cylinders, enabling smoother and more efficient system operation.

The 4WRKE valve is specifically designed to provide directional control while offering precise modulation of fluid flow based on an electrical input. Its ability to regulate flow and pressure allows it to be used in various industries where exact control is needed for hydraulic systems.

Key Characteristics of the 4WRKE Hydraulic Proportional Valve

- 4-Way Valve:

- The 4WRKE valve is a 4-way valve, which means it has four ports:

- P (Pressure): The inlet port where pressurized hydraulic fluid enters the valve from the hydraulic pump.

- T (Tank): The outlet port where fluid is returned to the hydraulic reservoir or tank.

- A and B (Workports): These are the ports that connect to the hydraulic actuator (e.g., cylinders or motors). Depending on the valve’s position, fluid is directed either to A or B, causing the actuator to move in a specific direction.

- The 4WRKE valve is a 4-way valve, which means it has four ports:

- 3-Position Design:

- The 4WRKE valve typically has three positions, which refer to the states in which the valve can be placed:

- Neutral (Center Position): In this position, the valve blocks the fluid flow between the pressure port and workports, isolating the actuator. Fluid can be returned to the tank.

- Position 1: Fluid flows from the pressure port (P) to workport A, while workport B is connected to the tank for return.

- Position 2: Fluid flows from the pressure port (P) to workport B, while workport A is returned to the tank.

- The 4WRKE valve typically has three positions, which refer to the states in which the valve can be placed:

These positions allow the valve to control fluid flow direction and determine which side of the hydraulic actuator receives fluid.

- Proportional Control:

- The 4WRKE valve provides proportional control by adjusting the spool position in response to an electrical signal (usually 4-20 mA or 0-10V). The valve’s spool moves incrementally as the input signal changes, allowing for smooth modulation of fluid flow.

- Unlike simple on/off valves, the proportional nature of the valve allows for gradual changes in flow—enabling smoother starts and stops, as well as variable control of actuator speed and force.

- Electro-Hydraulic Actuation:

- The 4WRKE valve uses an electro-hydraulic actuator that consists of a proportional solenoid. The solenoid controls the movement of the valve spool based on the electrical control signal received.

- The position of the solenoid is directly proportional to the input signal, meaning that a higher electrical signal will move the spool further, increasing the flow rate of hydraulic fluid to the actuator.

Working Principle of the 4WRKE Hydraulic Proportional Valve

- Electrical Input:

- The control signal (e.g., 4-20 mA or 0-10V) is supplied to the valve’s proportional solenoid, which regulates the movement of the spool inside the valve.

- As the input signal increases, the solenoid moves the spool to a position that allows more fluid to flow through the valve, thereby controlling the actuator’s speed and force.

- Valve Spool Movement:

- The spool’s movement in the valve determines the fluid flow paths. The spool movement is directly related to the electrical signal; the greater the electrical signal, the further the spool moves, allowing more fluid to flow.

- In the neutral position, the valve prevents fluid from flowing to the actuator, allowing the system to rest or idle.

- In Position 1 or Position 2, the valve directs fluid flow to either workport A or B, respectively, depending on the direction of actuator movement needed.

- Flow Modulation:

- As the spool moves, the flow to the hydraulic actuator (e.g., cylinder or motor) is proportional to the input signal. This allows for smooth control over the actuator’s speed and force.

- Proportional valves like the 4WRKE can vary the flow continuously, unlike simple on/off valves that can only provide fixed flow rates.

- Neutral Position:

- When the valve is in the neutral position, the flow is blocked, and no fluid is delivered to the actuator. This ensures that the system is in standby mode or idle, with excess fluid being returned to the tank.

Applications of the 4WRKE Hydraulic Proportional Valve

- Mobile Equipment:

- The 4WRKE valve is used in mobile machinery such as construction equipment, agricultural machinery, and material handling equipment, where precise control of hydraulic actuators (e.g., hydraulic cylinders) is essential for smooth operation.

- Industrial Automation:

- In industrial automation, the valve is used to control hydraulic presses, robotic arms, and assembly line equipment that require fine control over actuator movement for operations like lifting, pressing, or handling materials.

- CNC Machines:

- In CNC (Computer Numerical Control) machines, the 4WRKE valve controls the hydraulic actuators responsible for precise movements in machining, cutting, or milling operations, enabling highly accurate and repeatable results.

- Hydraulic Test Systems:

- The valve is used in hydraulic test systems to provide precise flow and pressure control during testing procedures, ensuring that components are subjected to specific conditions for quality control or performance testing.

- Robotics and Automation:

- In robotic arms or automated assembly lines, the 4WRKE valve ensures accurate and smooth movement control for tasks like welding, material handling, assembly, and inspection.

- Marine and Offshore Equipment:

- In the marine and offshore industry, the 4WRKE valve is used to control hydraulic systems for cranes, winches, and steering systems where precise control is required under harsh conditions.

Advantages of the 4WRKE Hydraulic Proportional Valve

- High Precision:

- The proportional control capability of the 4WRKE valve allows for high precision in controlling actuator speed, position, and force. This makes it ideal for applications where accurate, smooth, and gradual movement is required.

- Smooth Operation:

- The continuous, variable flow control provided by the valve ensures that the actuators move smoothly, without jerks or abrupt starts and stops, enhancing the overall performance and longevity of the system.

- Energy Efficiency:

- Since the valve can adjust the flow to match the required load, it results in energy-efficient operation, reducing waste and saving power compared to systems that use full-flow, on/off valves.

- Flexible Control:

- The 4WRKE valve can be integrated with a wide range of control systems, such as PLCs, joystick controllers, or automated systems, providing operators with flexible options to adjust the actuator’s behavior.

- Reduced Mechanical Stress:

- The smooth and proportional operation reduces mechanical stresses on both the hydraulic system and the actuators, helping to extend the lifespan of components.

Summary of the 4WRKE Hydraulic Proportional Valve

- The 4WRKE is a 4-way, 3-position proportional directional control valve designed to control the flow and direction of hydraulic fluid in a system based on an electrical input.

- It features proportional control, meaning the valve adjusts fluid flow in response to an input signal, allowing smooth and precise control of hydraulic actuators.

- The valve is commonly used in mobile machinery, industrial automation, CNC machines, robotics, and hydraulic testing, providing high precision, smooth operation, and energy efficiency.

Advantages:

- High precision, smooth operation, energy efficiency, flexible integration, and reduced mechanical stress are key benefits of the 4WRKE valve.

The 4WRKE hydraulic proportional valve is ideal for demanding applications that require precise, smooth, and reliable control of hydraulic fluid in systems such as construction equipment, robotic systems, and CNC machinery.

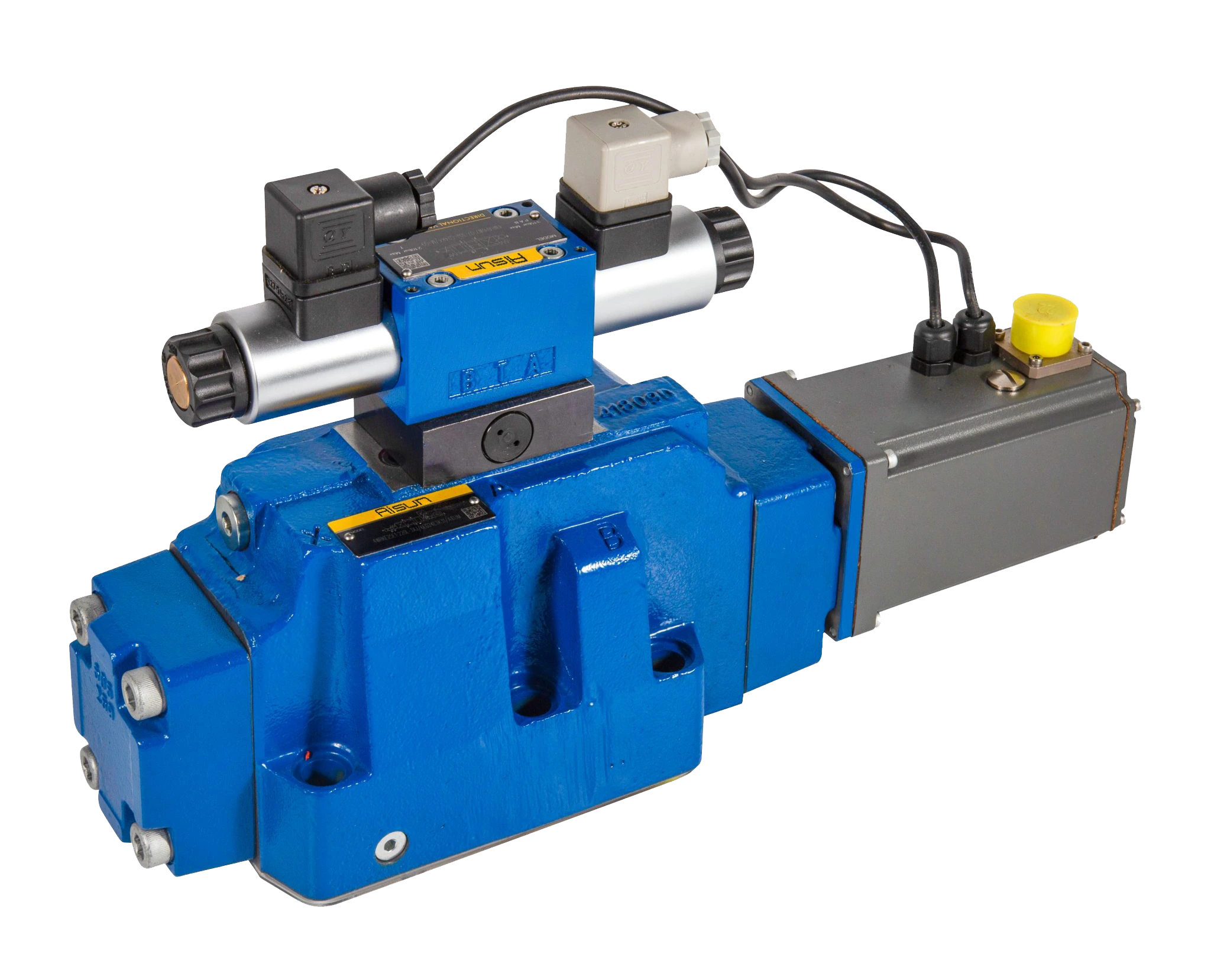

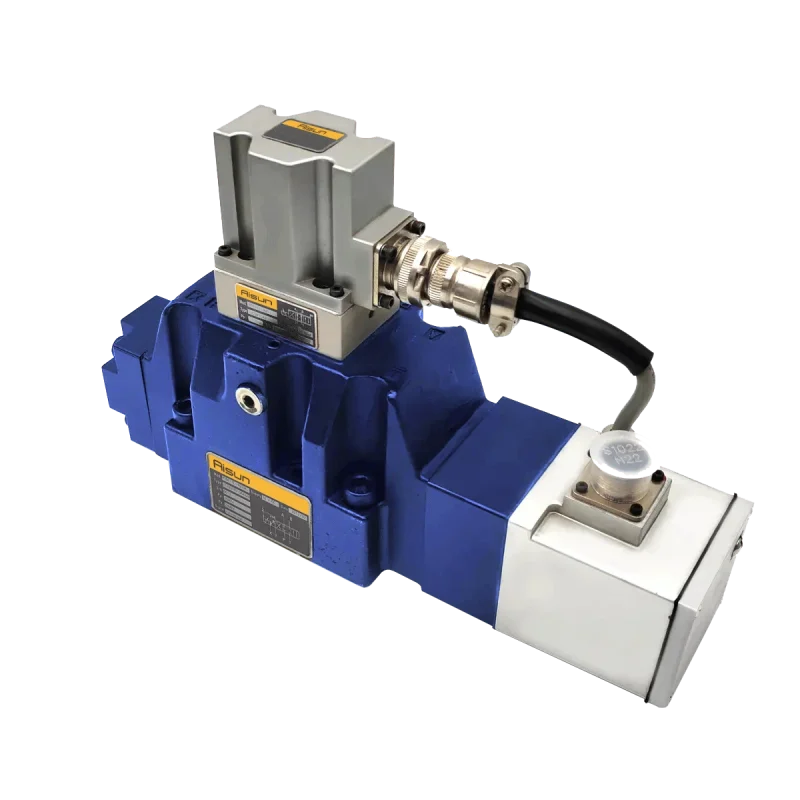

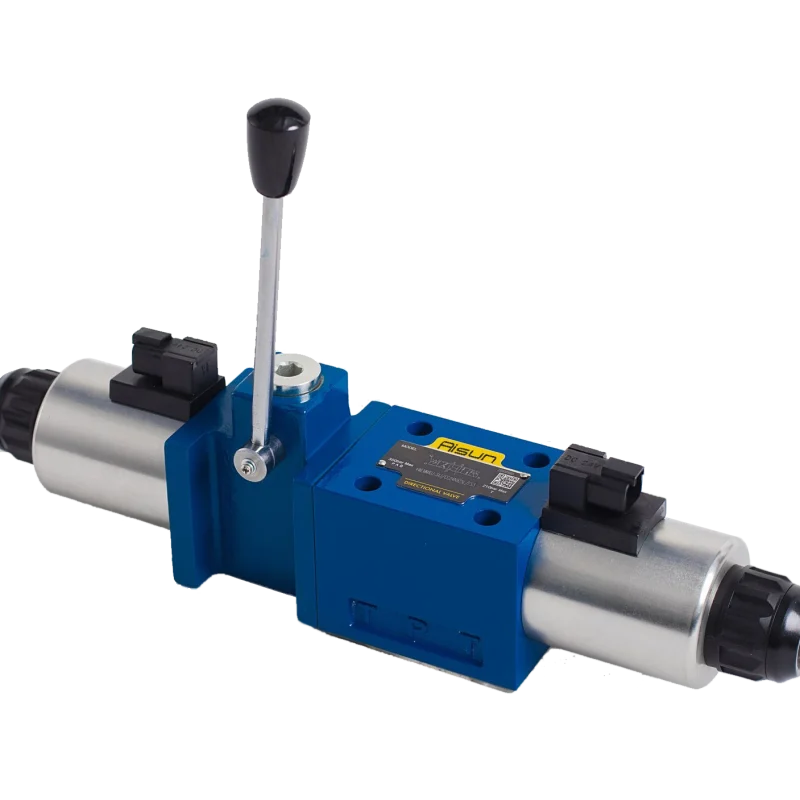

hydraulic Proportional Directional valves 4WRKE

Proportional Directional valves 4WRKE

In the field of fluid power control, the Electro-Hydraulic Proportional Directional Valve (EHPDV) is a critical component that plays a vital role in regulating the flow and direction of hydraulic fluids. Among the various types of EHPDVs available, the 4WRK… stands out as a high-performance, two-stage proportional directional control valve. This valve offers precise control over flow size and direction, making it an ideal choice for applications requiring accurate hydraulic control.

The 4WRKE type proportional directional control valve comprises several key components, including the pilot control valve, housing, main spool, covers, centering spring, inductive position transducer, and pressure reducing valve. Each component serves a specific purpose in ensuring the valve’s smooth operation and precise control over fluid flow.