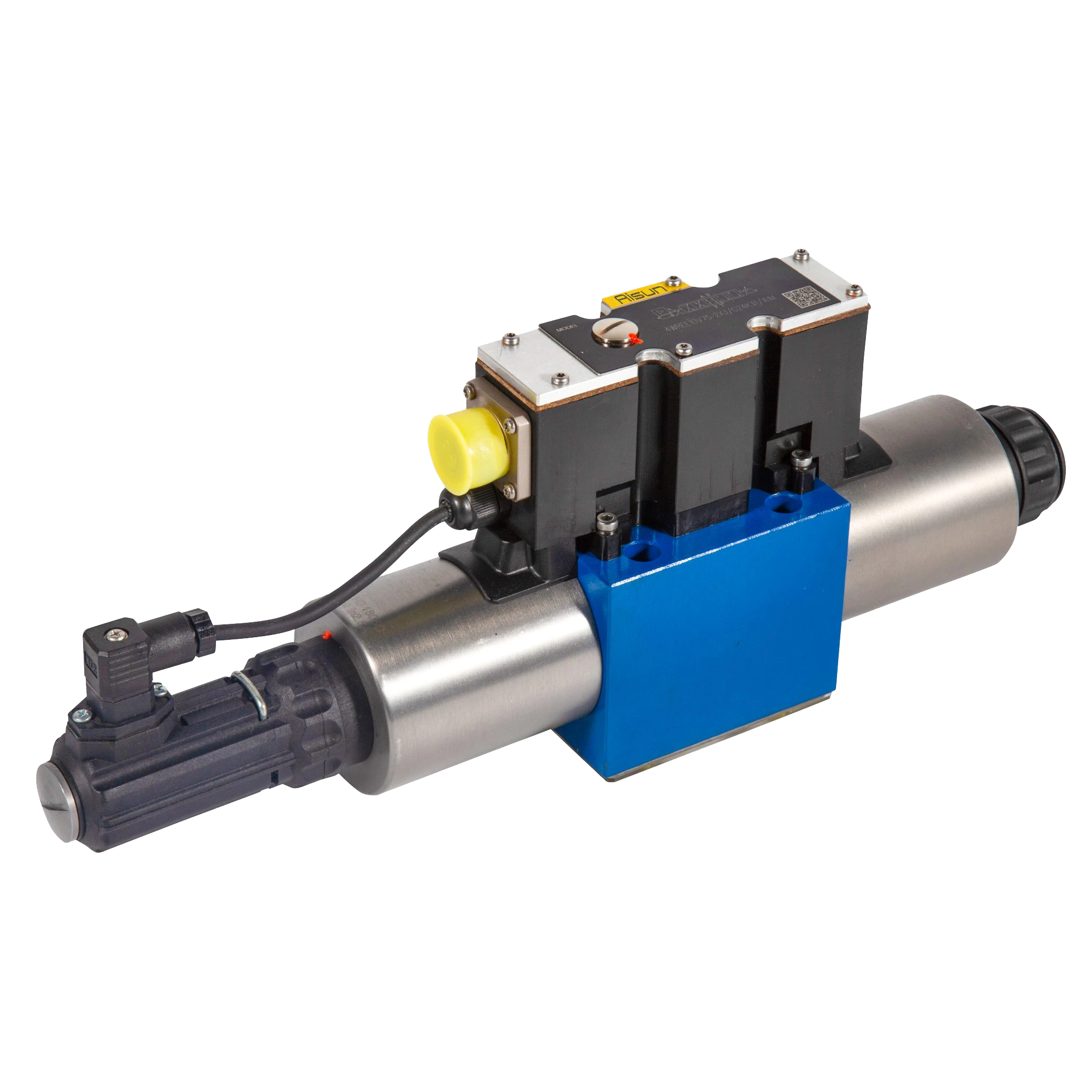

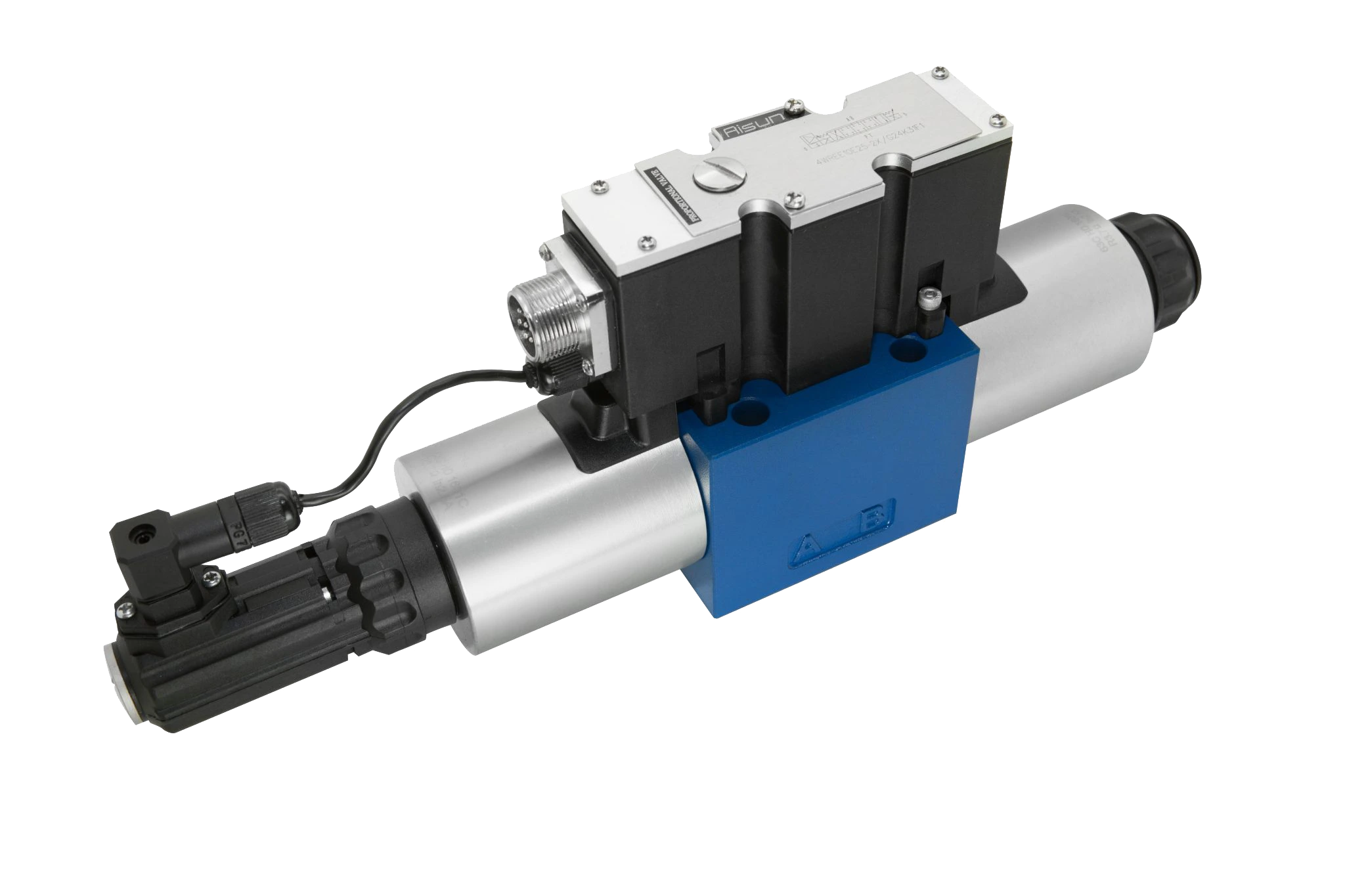

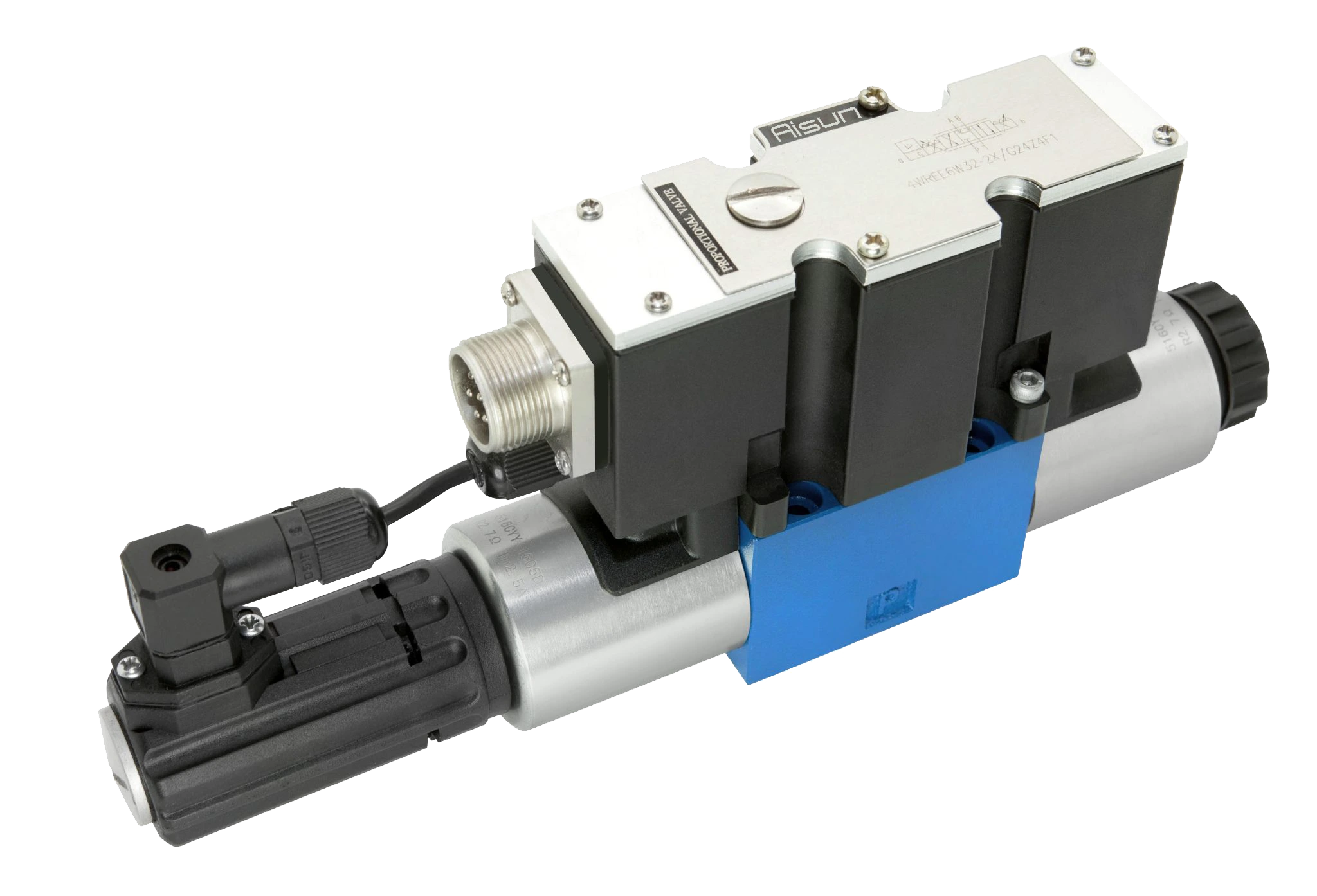

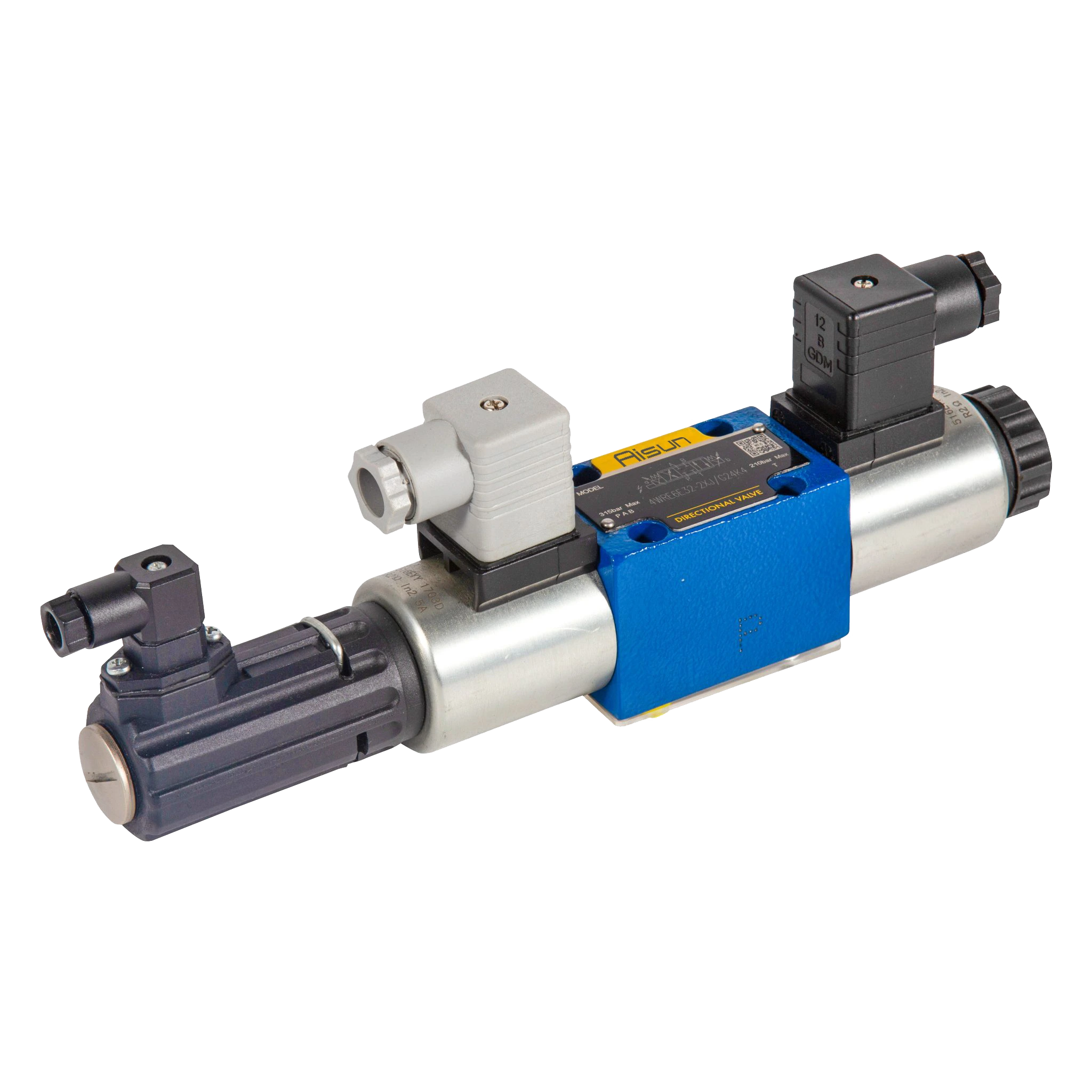

Proportional Directional Control Valve 4WRE

A 4WRE hydraulic valve is a proportional directional control valve used in hydraulic systems for controlling fluid flow and direction with precise modulation. Similar to the 4WRA valve, the 4WRE is a 4-way, 3-position proportional valve but with specific differences in its design and application. The 4WRE valve is part of the family of electro-hydraulic proportional valves, which combine the capabilities of both proportional control and directional control in hydraulic systems.

Key Characteristics of the 4WRE Hydraulic Proportional Valve

- 4-Way Valve:

- 4WRE is a 4-way valve, meaning it has four fluid ports:

- P (Pressure): The input port where pressurized fluid enters the valve from the hydraulic pump.

- T (Tank): The output port where fluid returns to the tank or reservoir.

- A and B (Workports): The two output ports that connect to the hydraulic actuator (e.g., hydraulic cylinders or motors) for fluid distribution depending on the valve position.

- 4WRE is a 4-way valve, meaning it has four fluid ports:

- 3-Position Design:

- The 3-position feature means the valve has three distinct spool positions, which determine the direction and flow of the hydraulic fluid. These positions typically include:

- Neutral (Center Position): The valve blocks the flow between ports, effectively stopping fluid movement to the actuator, with fluid bypassed to the return port (T).

- Position 1: The valve directs fluid from the pressure port (P) to workport A, while fluid from workport B is returned to the tank (T).

- Position 2: The valve directs fluid from the pressure port (P) to workport B, while fluid from workport A is returned to the tank (T).

- The 3-position feature means the valve has three distinct spool positions, which determine the direction and flow of the hydraulic fluid. These positions typically include:

- Proportional Control:

- The 4WRE valve uses proportional control to vary the flow rate based on the input signal, which is typically an electrical signal (e.g., current or voltage). This allows for precise, continuous modulation of fluid flow, providing more control over actuator speed, force, and position compared to on/off valves.

- Proportional control allows the valve to modulate how far the spool moves, which directly impacts the flow rate through the valve. As the input signal increases, the spool moves further, allowing more fluid flow, while a lower input signal results in less movement and lower flow.

- Electro-Hydraulic Control:

- The 4WRE valve typically uses an electro-hydraulic actuator, which consists of a solenoid (electrical coil) that moves the valve spool. The solenoid receives a control signal from an external controller, such as a PLC (Programmable Logic Controller) or a joystick, which determines how much the spool moves and consequently how much fluid flows to the actuator.

- The solenoid’s movement is proportional to the electrical input, making this valve suitable for applications that require precise control, such as variable-speed systems or systems where smooth transitions in fluid flow are needed.

Working Principle of the 4WRE Proportional Valve

- Electrical Signal Input:

- The valve is controlled by an external electrical signal, which is typically a current (4-20mA) or voltage signal. This input controls the proportional solenoid that moves the valve spool.

- Spool Movement and Flow Control:

- When an electrical signal is applied to the solenoid, it moves the valve spool in proportion to the signal strength. As the spool moves, it opens or closes the fluid passages between the valve ports.

- If the signal increases, the solenoid moves the spool further, allowing more fluid to pass through to the actuator. Conversely, a decrease in the signal results in a reduced flow rate as the spool moves back toward its neutral position.

- Fluid Direction:

- The valve allows the hydraulic fluid to flow from the pressure port (P) to either workport A or workport B, depending on the spool’s position. The flow can be directed to either of the two workports in a controlled manner, which enables precise control over actuator movement (e.g., hydraulic cylinders or motors).

- Neutral Position:

- In the neutral position, the valve blocks the flow to the actuators, and any excess fluid is diverted to the tank or reservoir. This stops actuator movement and isolates the system for standby or idle conditions.

Advantages of the 4WRE Hydraulic Proportional Valve

- Precision Control:

- The 4WRE valve offers highly precise control over hydraulic actuators by adjusting the fluid flow and direction proportionally based on an electrical signal. This makes it ideal for applications requiring fine control, such as in robotics, CNC machines, or automated manufacturing systems.

- Smooth Operation:

- Because the valve uses proportional control, the fluid flow is gradually adjusted, leading to smoother operation of hydraulic actuators. This results in smoother starts, stops, and speed control, minimizing shocks and jerks that can occur with on/off valves.

- Energy Efficiency:

- Proportional control allows for more energy-efficient operation by delivering just the amount of hydraulic power required for the task. This reduces the waste of energy that can occur with full-flow, on/off valves.

- Flexibility:

- The 4WRE valve allows for easy integration with control systems like PLCs, joystick controls, or hydraulic controllers, providing flexibility for operators to precisely adjust the flow and speed of the hydraulic actuators.

- Enhanced System Performance:

- The ability to modulate flow based on input signals improves the overall performance of the hydraulic system by providing optimal force and speed control for the actuator without overdriving or underdriving them.

Applications of the 4WRE Proportional Valve

- Mobile Machinery:

- The 4WRE valve is commonly used in mobile equipment like construction machinery, agricultural machinery, and material handling equipment, where smooth, controlled hydraulic movements are required.

- Industrial Automation:

- In industrial automation systems, the 4WRE valve is used to control hydraulic actuators that drive presses, robots, conveyor belts, and other machinery, where precise control is crucial.

- CNC Machines:

- In CNC (Computer Numerical Control) machines, the 4WRE valve provides accurate control of hydraulic actuators to achieve fine movements for machining, cutting, or milling.

- Robotics:

- In robotic arms or other automated systems, the 4WRE valve ensures smooth and precise motion control, crucial for tasks like assembly, welding, or material handling.

- Test Systems:

- The 4WRE valve is used in hydraulic test systems to precisely control the pressure and flow of hydraulic fluid during tests, ensuring accurate and repeatable results.

Summary of the 4WRE Hydraulic Proportional Valve

- The 4WRE is a 4-way, 3-position proportional directional control valve used in hydraulic systems to provide precise control over fluid flow and direction.

- It uses an electro-hydraulic solenoid that modulates the valve spool based on an input electrical signal, allowing for proportional flow control.

- The valve is commonly used in applications where precise, smooth, and energy-efficient control of hydraulic actuators (like cylinders and motors) is required, such as in mobile equipment, industrial automation, CNC machines, and robotics.

Advantages:

- Precise control of hydraulic fluid flow and actuator movements.

- Smooth operation with minimal shock.

- Energy-efficient and flexible for integration with automated control systems.

The 4WRE valve provides enhanced performance in systems that require fine control and is ideal for sophisticated hydraulic applications.

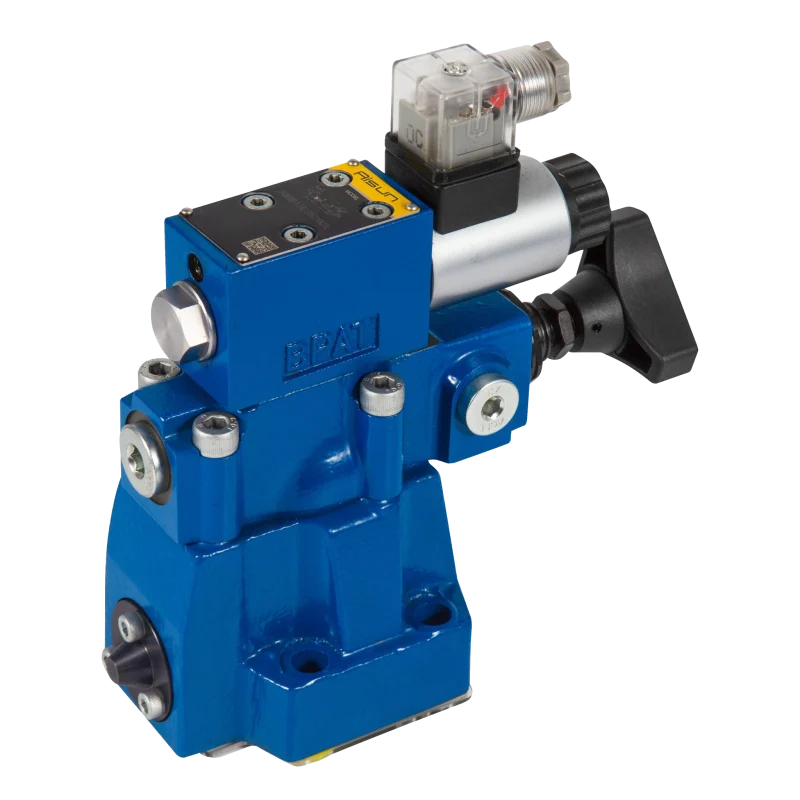

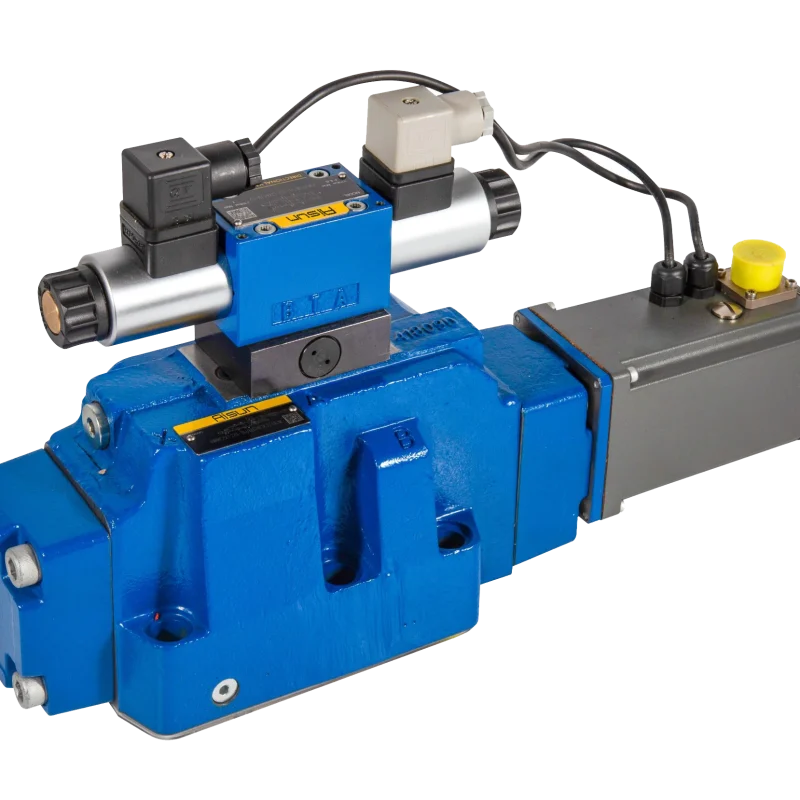

Proportional directional valves 4WRE

Proportional directional valves 4WRE

The 4WRE(E) type Proportional Control Valve is a highly advanced and efficient valve used in fluid control systems. It is designed with various components that work together to provide precise and adaptable control.

- Direct operated proportional directional

- valve with electrical position feedback

- Closed loop control of the direction and size of a flow

- Operation is by proportional solenoids with a central thread and removable coil

- For subplate mounting: Porting pattern conforms to ISO 4401

- Spring centred control spool

- Integrated electronics (OBE) with voltage

- input or current input (A1 resp. F1)

- 4WRE separate order: analogue module amplifier