pressure control valves DB and DBW

The terms DB and DBW in hydraulic systems also refer to pressure control valves that regulate the pressure within a hydraulic circuit. These valves are used to maintain and control the pressure to ensure the system operates within safe and efficient limits. Let’s dive into each valve type and their role in pressure control.

DB Valve (Pressure Control Valve)

The DB valve stands for “Directional Valve with Pressure Control”, often referred to in terms like “Pressure Relief Valve” or “Pressure Setting Valve.” This type of valve primarily focuses on regulating the hydraulic pressure in the system.

Function:

- Pressure Relief: The DB valve is used to prevent the system from exceeding a certain pressure level. It opens to divert the flow of fluid when the pressure reaches a preset limit, protecting the hydraulic system from damage.

- Pressure Regulation: It ensures the system operates within a desired pressure range by controlling the relief point or maintaining a specific pressure setting.

Working Principle:

- The DB valve typically consists of a spring-loaded mechanism that holds a valve element (such as a spool or poppet) in place. When the hydraulic pressure exceeds the preset level, the valve element moves, allowing fluid to flow through an alternate path and relieving excess pressure.

Common Types:

- Pressure Relief Valve: Limits the maximum pressure in the system by bypassing excess fluid when the pressure reaches the preset value.

- Pressure Reducing Valve: Ensures that the pressure in a particular part of the system is lower than the rest of the system.

- Sequence Valve: Used to control the sequence of pressure buildup in a series of operations, ensuring that the correct pressure is achieved before moving to the next stage.

Common Applications:

- Overpressure Protection: DB valves are crucial for protecting hydraulic circuits from overpressure, which could cause system damage or failure.

- Pressure Control in Actuators: They are often used to control the pressure in hydraulic actuators like cylinders or motors.

DBW Valve (Pressure Control Valve with Wet Switch)

A DBW valve, in the context of pressure control, often refers to “Directional Pressure Control Valve with Wet Switch”, typically used in more complex hydraulic systems. The “wet switch” feature refers to a type of valve that is designed to handle conditions where moisture or fluid may directly interact with the switching or regulating components of the valve. This makes the valve more resilient and reliable in challenging environments.

Function:

- Pressure Relief and Regulation: Like the DB valve, the DBW valve regulates pressure but with additional features, such as electronic or electro-hydraulic control for more precise operation.

- Advanced Pressure Control: DBW valves can incorporate additional functions like pressure compensation, automatic flow adjustment, or system diagnostics, making them more suitable for complex hydraulic systems that require high precision.

Working Principle:

- Similar to the DB valve, the DBW valve includes a mechanism that opens or closes based on the pressure levels in the system, but it integrates electronic or hydraulic controls for finer adjustments. In some configurations, the “wet switch” aspect ensures that the valve can operate in environments with a lot of moisture without malfunctioning.

Common Features:

- Electro-Hydraulic Operation: The valve may use electric signals to control hydraulic fluid flow, offering enhanced control over the pressure.

- Moisture Resistance: The wet switch function makes the valve suitable for environments where water or moisture could be present and may interfere with mechanical switches.

- Automation and Precision: DBW valves often feature electronic control systems that enable precise adjustments to pressure levels in real-time.

Common Applications:

- High-Precision Systems: DBW valves are used in systems where high precision and automated control of pressure are necessary, such as in aerospace, robotics, or heavy machinery.

- Mobile Equipment: These valves are also found in mobile applications like construction or agricultural equipment, where both hydraulic pressure control and resistance to harsh conditions are required.

Differences Between DB and DBW Pressure Control Valves:

- Control Mechanism:

- DB Valve: Primarily uses mechanical or spring-loaded mechanisms to control pressure.

- DBW Valve: Uses electronic or electro-hydraulic control, offering more precise and automated pressure management.

- Environmental Resistance:

- DB Valve: May not be designed for use in wet or moisture-heavy environments.

- DBW Valve: Designed with “wet switch” technology to operate reliably even in moist or challenging environments.

- Application Complexity:

- DB Valve: Typically used in simpler systems where basic pressure relief or regulation is required.

- DBW Valve: Used in more advanced and automated systems that require finer control and higher functionality.

Summary of DB and DBW Pressure Control Valves:

- DB Valve: A type of pressure control valve used to regulate or limit pressure in hydraulic systems. It’s often a mechanical or spring-operated valve, such as a pressure relief valve, pressure reducing valve, or sequence valve.

- DBW Valve: A more advanced version, typically featuring electronic or electro-hydraulic control, designed for complex systems with higher precision and the ability to operate in moist environments.

Both types of valves are essential for maintaining hydraulic system integrity and ensuring safe operation, but the DBW valve offers more sophisticated and automated pressure control for advanced applications.

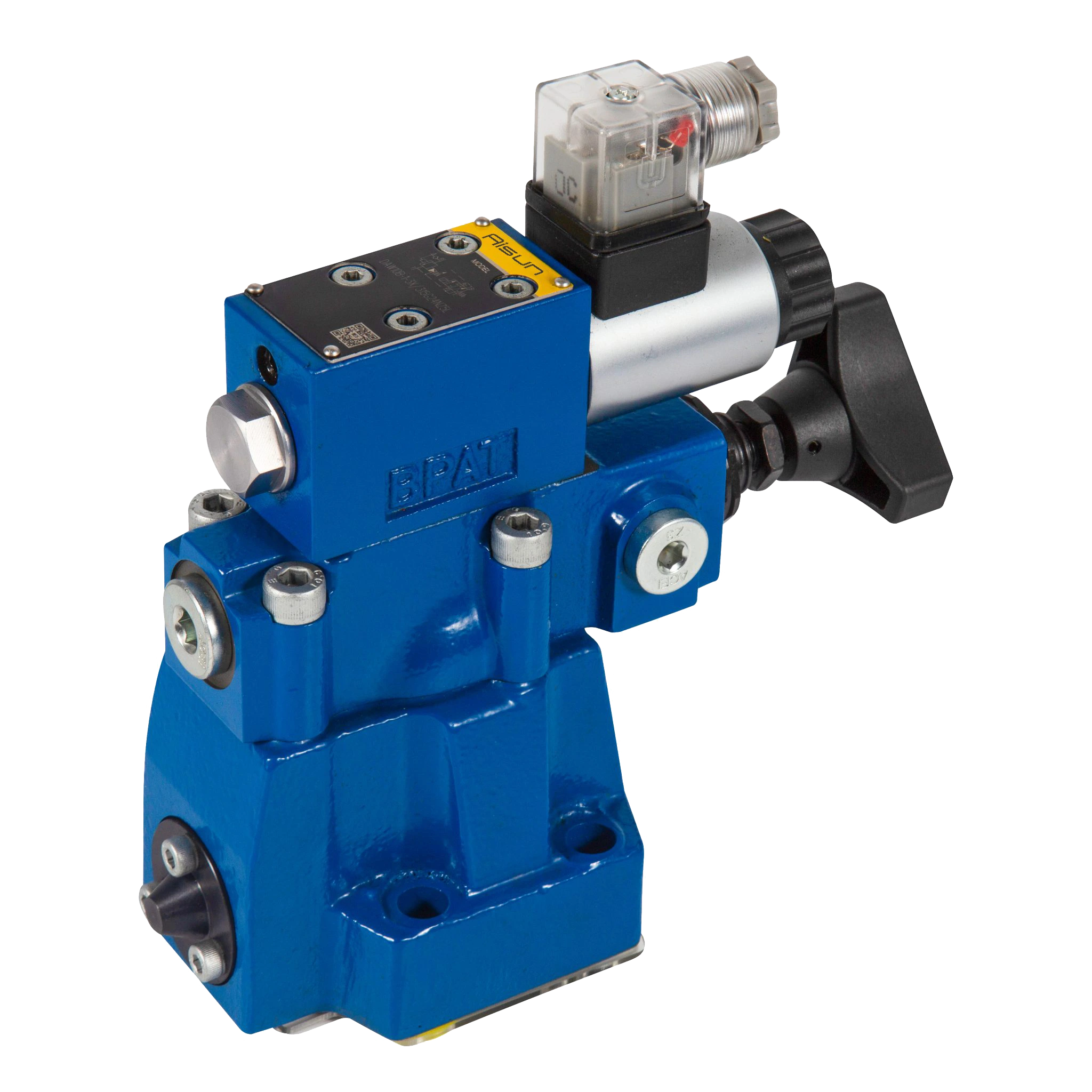

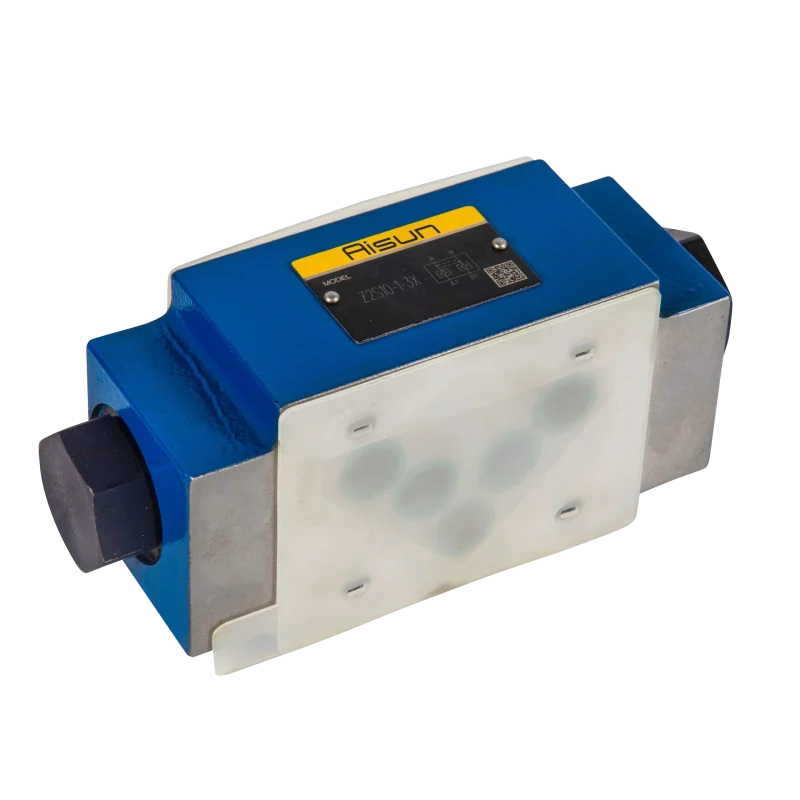

Pressure control valves DB and DBW

Pressure control valves DB and DBW

The DB and DBW pressure control valves are pilot operated relief valves.

They are used to limit (DB), or to limit and unload by solenoids (DBW) of working pressure.

- ◆ Size 10 to 32

- ◆ Maximum working pressure 350 bar

- ◆ Maximum working flow 650L/min

- ◆Subplate mounting: size 10/20/30

- ◆Threaded connection:size 10/15/20/25/32

- ◆Setting pressure:5MPa/10MPa/20MPa/31.5bar/35MPa

- ◆Flow rate:250L/min (for size 10 only),500L/min (for size 15, 20, 25),650L/min (for size 32 only)