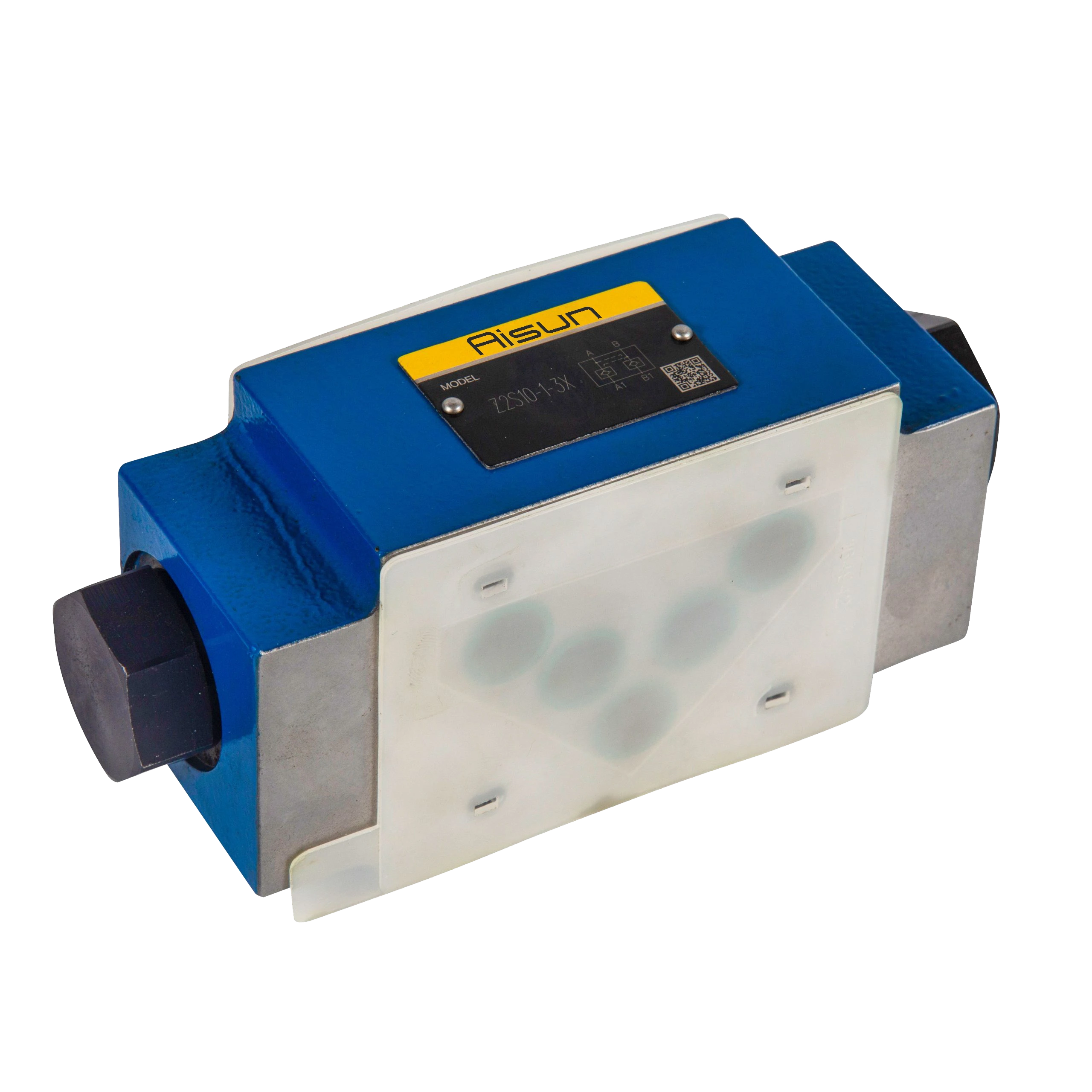

Aisun Z2S Check Valve:

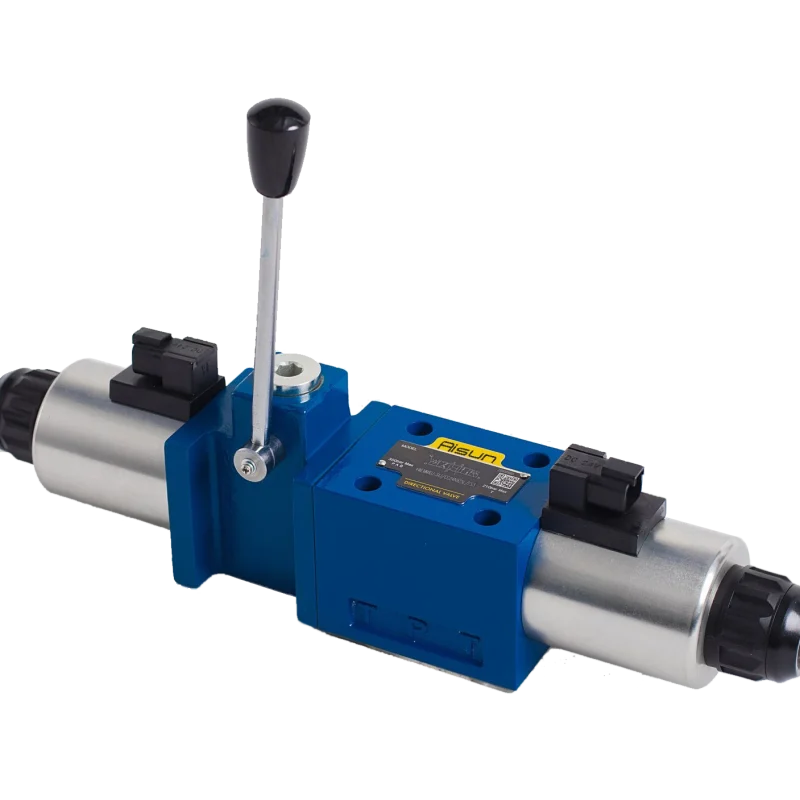

1. Functionality:

– The primary function of the Aisun Z2S check valve is to control the direction of hydraulic fluid in a system. It permits flow in one direction while preventing reverse flow, ensuring that fluid only moves in the desired direction.

– It helps protect the system from damage caused by backflow, which can lead to issues like pump damage, actuator malfunction, or contamination of the system.

– It is a spring-loaded valve, meaning the valve is held in the closed position by a spring and only opens when the pressure on the inlet side exceeds the spring force.

2. Design and Construction:

– Compact Design: The Z2S check valve is designed to be compact and durable, making it suitable for use in confined spaces where space is limited.

– High-Quality Materials : Aisun hydraulic uses high-quality materials such as steel and hardened steel for the internal components and housing to ensure long-lasting performance and resistance to wear, pressure, and corrosion.

– Spring-Loaded Poppet: The valve consists of a poppet mechanism that is held in place by a spring. When fluid flows in the permitted direction, the poppet is pushed open, allowing the fluid to pass. If the fluid attempts to reverse, the spring forces the poppet back against the seat, blocking the flow and preventing backflow.

3. Operation:

– Forward Flow: When hydraulic fluid flows in the intended direction (i.e., towards the inlet side), the pressure of the fluid pushes the poppet open, allowing the fluid to flow through the valve.

– Backflow Prevention: If the flow tries to reverse, the spring-loaded mechanism forces the poppet to close tightly, blocking the reverse flow and preventing damage to the hydraulic system.

– Automatic Operation: The check valve operates automatically, without the need for any external power sources or controls. It simply reacts to changes in fluid pressure, making it a passive yet critical component of the hydraulic system.

4. Applications:

– Industrial Hydraulics: The Z2S check valve is commonly used in hydraulic systems for industrial machinery, such as presses, injection molding machines, and material handling systems.

– Mobile Equipment: It is also used in mobile machinery like construction equipment (excavators, cranes, bulldozers) to ensure safe and efficient operation of the hydraulic system.

– Hydraulic Power Packs: The valve is used in hydraulic power units, where it helps regulate fluid flow direction and prevent backpressure that could damage pumps and motors.

– Agricultural Equipment: Equipment like tractors, harvesters, and loaders can also benefit from the use of Z2S check valves for flow direction control and system protection.

5. Pressure Range:

– The Z2S check valve is designed to operate under a wide range of pressure levels, typically from 35 bar (500 psi) up to 350 bar (5075 psi), depending on the model and the specific application requirements.

– The valve’s design ensures it can handle these high-pressure conditions reliably, protecting the system from pressure spikes that could otherwise cause failure.

6. Flow Rate Capacity:

– The flow capacity of the Z2S check valve can vary depending on the specific model and size, with larger valves designed for high-flow applications.

– The flow rates that the Z2S valve can accommodate are typically in the range of 20 L/min (5.28 gpm) to 500 L/min (132 gpm) or more, depending on the specific version of the valve.

– The design of the valve allows for minimal pressure drop when the valve is open, ensuring that system efficiency is maintained during operation.

7. Size and Mounting:

– Sizes: The Z2S check valve is available in various sizes to fit different hydraulic system requirements, ranging from smaller models for compact systems to larger versions for high-flow, high-pressure applications.

– Mounting Options: The valve is designed for easy integration into hydraulic circuits and is typically screw-in or flange-mounted, offering flexibility in installation. It can be used as a standalone component or integrated into manifold systems for more complex configurations.

– Compact and Versatile: The compact size of the Z2S valve allows it to be installed in tight spaces, and it can be used in a wide range of industrial, mobile, and agricultural equipment.

8.Sealing and Materials:

– The valve is equipped with high-quality seals to prevent leakage and ensure tight shutoff when the valve is closed. These seals are made from materials like NBR (Nitrile Butadiene Rubber), FPM (Fluorocarbon), or EPDM (Ethylene Propylene Diene Monomer), which are resistant to heat, chemicals, and various hydraulic fluids.

– The choice of materials ensures that the valve can perform reliably in harsh operating conditions and provide long service life.

9. Performance Features:

– Low Pressure Drop: One of the key features of the Z2S valve is its low pressure drop during forward flow, which helps improve overall system efficiency by reducing energy loss.

– High Flow Capacity: The valve is designed to handle high flow rates, making it suitable for both low-flow and high-flow hydraulic systems.

– Durability: The spring-loaded poppet design and high-quality materials ensure that the valve performs reliably even in demanding environments and under high pressure.

– Responsive Action: The valve’s quick and automatic response to pressure changes makes it an essential component for maintaining the integrity of hydraulic systems.

10. Adjustability:

– The Z2S check valve typically comes in non-adjustable versions. However, some variants may offer the ability to adjust spring tension to customize the cracking pressure (the pressure required to open the valve).

– This adjustability can help fine-tune the valve’s performance to meet specific system requirements, such as controlling the point at which the valve begins to open.

11. Certifications and Compliance:

– Aisan hydraulic components, including the Z2S check valve, are often designed and manufactured in compliance with international standards, such as ISO 9001 for quality management and ISO 14001 for environmental management.

– The valves also meet safety and performance standards commonly required in industrial, mobile, and agricultural applications.

Advantages of Aisan Z2S Hydraulic Check Valves:

– Reliable Backflow Prevention: The Z2S check valve ensures that fluid only flows in the correct direction, preventing damage from backflow and protecting expensive system components like pumps and actuators.

– Efficient Flow Control: It offers minimal resistance to flow when open, helping maintain energy efficiency and overall system performance.

– Durability: Designed for long service life, the Z2S check valve can withstand high pressures and harsh operating conditions without significant wear or failure.

– Compact Design: Its compact size makes it suitable for a variety of hydraulic applications, even in systems where space is limited.

– Easy Integration: With various mounting options, the Z2S valve can be easily integrated into most hydraulic systems, from simple to complex circuits.

Conclusion:

The Aisan Z2S hydraulic check valve is a key component for ensuring the proper flow direction and protecting hydraulic systems from the harmful effects of backflow. By preventing reverse fluid flow, it helps safeguard pumps, motors, and other components while maintaining system efficiency. With its durable design, low-pressure drop, and reliable operation, the Z2S check valve is well-suited for a wide range of applications in industrial, mobile, and agricultural hydraulics.

Modular Check Valve Z2S

Modular Check Valve Z2S

In the realm of hydraulic systems, precision control and reliability are paramount. The Z2S type modular hydraulic operated check valve emerges as a pivotal component in this landscape, featuring a sandwich plate design and excelling in providing leakage-free closure for one or two actuator ports, even during extended standstill periods. This article aims to unravel the intricate workings of the Z2S6 valve, shedding light on its design principles, operational mechanisms, and applications within hydraulic systems.

The Z2S6 valve stands as a pilot-operated check valve, ingeniously crafted in a sandwich plate design. Its primary function is to ensure the seamless closure of actuator ports, preventing any undesired fluid flow during prolonged periods of inactivity. The valve allows for unimpeded fluid flow in the A1 to A2 or B1 to B2 direction, and conversely, it efficiently blocks flow in the opposite direction.