Flow control valve Z2FS

The Z2FS hydraulic flow control valve is a specific type of flow control valve used in hydraulic systems to regulate the flow of hydraulic fluid while providing pressure relief functionality. The Z2FS valve typically combines flow control and pressure relief in a single compact unit, making it ideal for applications where both flow rate regulation and pressure protection are necessary.

The “Z2FS” designation refers to a particular model or series of valves that offer both adjustable flow control and pressure relief capabilities in hydraulic circuits, and these valves are often used in various industrial applications, mobile machinery, and fluid power systems.

Features of the Z2FS Hydraulic Flow Control Valve:

- Flow Control: The primary function of the Z2FS valve is to regulate the flow of hydraulic fluid to an actuator (e.g., a hydraulic cylinder or motor) in a hydraulic circuit. It can adjust the flow rate to control the speed of the actuator, ensuring smooth and predictable movement.

- Pressure Relief: In addition to controlling flow, the Z2FS valve typically includes a pressure relief valve This means the valve can also protect the hydraulic system from excessive pressure by diverting excess fluid when the system pressure exceeds a set limit, thus preventing potential damage to components or the system itself.

- Compact Design: The Z2FS valve is often designed in a compact and integrated form, making it easy to install within hydraulic circuits without taking up excessive space. This is especially important in applications where space is limited, such as in mobile equipment or compact industrial systems.

- Pressure-Compensated (in some versions): Some Z2FS valves are pressure-compensated, which means that they automatically adjust the flow rate in response to changes in system pressure. This feature helps maintain a consistent speed for actuators, regardless of load variations or pressure changes in the system.

- Adjustability: The Z2FS valve can usually be adjusted manually to change the flow rate and set the desired pressure relief value. This allows for customized operation based on the specific needs of the hydraulic system and application.

- Bidirectional Flow Control: The Z2FS valve can control fluid flow in both directions for double-acting actuators, making it suitable for use with cylinders and motors that require flow regulation during both extension and retraction.

- Built-in Check Valve (Optional): Some versions of the Z2FS valve include a built-in check valve to prevent backflow and ensure that the fluid flows in the intended direction. This is especially useful in circuits where backflow could affect system performance or safety.

How the Z2FS Flow Control Valve Works:

The operation of the Z2FS valve can be broken down into two main functions: flow control and pressure relief.

1. Flow Control:

- The valve regulates the rate of fluid flow to the actuator by adjusting the size of the orifice through which the fluid passes. The size of the orifice can be adjusted, either manually or automatically (depending on the design of the valve), to control the speed of the hydraulic actuator.

- When fluid flows through the valve, the flow rate is determined by the setting of the valve, allowing the actuator (such as a cylinder or motor) to move at the desired speed.

2. Pressure Relief:

- The pressure relief function of the Z2FS valve ensures that, if the system pressure exceeds a preset level, the valve will open to divert the excess fluid. This helps protect the hydraulic system from overpressure, which could otherwise damage components such as the pump, valves, hoses, or actuators.

- The pressure relief feature ensures that the system operates safely within its pressure limits, maintaining the integrity of the entire hydraulic circuit.

3. Adjustability:

- Users can manually adjust the flow control setting to determine the desired flow rate. This allows the valve to provide the correct flow to the actuator, whether the application requires a slow, controlled movement or a faster operation.

- The pressure relief setting can also be adjusted to set the maximum allowable system pressure, ensuring that the system remains protected from excessive pressure.

4. Bidirectional Operation:

- The Z2FS valve is typically used in circuits with double-acting actuators, where fluid is needed in both directions (e.g., for extending and retracting a hydraulic cylinder).

- It regulates the flow in both directions to ensure that the actuator moves at a consistent speed during both extension and retraction, depending on the flow settings.

Applications of the Z2FS Hydraulic Flow Control Valve:

The Z2FS valve is used in various hydraulic applications where both flow control and pressure relief are required. Common applications include:

- Hydraulic Cylinders: In systems with double-acting hydraulic cylinders, the Z2FS valve regulates the speed of the cylinder’s extension and retraction while protecting the system from excessive pressure.

- Hydraulic Motors: In hydraulic motor circuits, the valve controls the flow and speed of the motor and provides pressure relief to prevent damage to the motor or other components.

- Mobile Equipment: The Z2FS valve is commonly used in construction machinery, agricultural equipment, and material handling equipment, where precise control of actuator speed and protection against overpressure are crucial.

- Industrial Systems: In manufacturing and processing equipment, the valve helps control the speed of actuators in robotic arms, presses, or clamping systems, while also ensuring the system operates safely under varying pressure conditions.

- Pressure Control Systems: In hydraulic circuits that require both flow control and pressure regulation, the Z2FS valve helps maintain a balance between flow and pressure, ensuring smooth, efficient, and safe operation.

Advantages of the Z2FS Hydraulic Flow Control Valve:

- Compact and Integrated Design: The Z2FS valve combines both flow control and pressure relief functionality into a single unit, making it compact and easy to integrate into hydraulic circuits.

- Pressure Protection: By offering pressure relief, the valve helps protect the hydraulic system from overpressure, reducing the risk of system failure and extending the life of components.

- Flow Control: It provides precise control of actuator speed, allowing for smooth and consistent operation, even when the load varies.

- Bidirectional Control: The ability to control flow in both directions makes it ideal for double-acting cylinders and motors, ensuring consistent speed in both the extension and retraction phases.

- Customizable Settings: The valve can be adjusted to meet specific system requirements for both flow rate and pressure relief, allowing for flexible and adaptable performance.

Considerations When Using the Z2FS Valve:

- System Compatibility: Ensure that the Z2FS valve is compatible with the hydraulic system’s pressure and flow rate requirements. Oversized or undersized valves could lead to poor performance or inefficiencies.

- Regular Maintenance: As with all hydraulic components, regular maintenance is needed to ensure the valve operates correctly. This includes checking for leaks, verifying pressure settings, and inspecting the internal components.

- Pressure Setting Accuracy: The pressure relief setting must be calibrated correctly to prevent overpressure conditions that could cause damage to the system.

The Z2FS hydraulic flow control valve is a versatile and essential component in hydraulic systems where precise control of flow and pressure is needed. By combining both flow regulation and pressure relief in a single unit, the Z2FS valve helps maintain the performance and safety of hydraulic circuits. It is commonly used in applications with double-acting actuators, such as hydraulic cylinders and motors, in industries ranging from mobile equipment to manufacturing and industrial processes. The valve’s ability to ensure smooth actuator movement while providing pressure protection makes it a reliable and effective solution in many hydraulic systems.

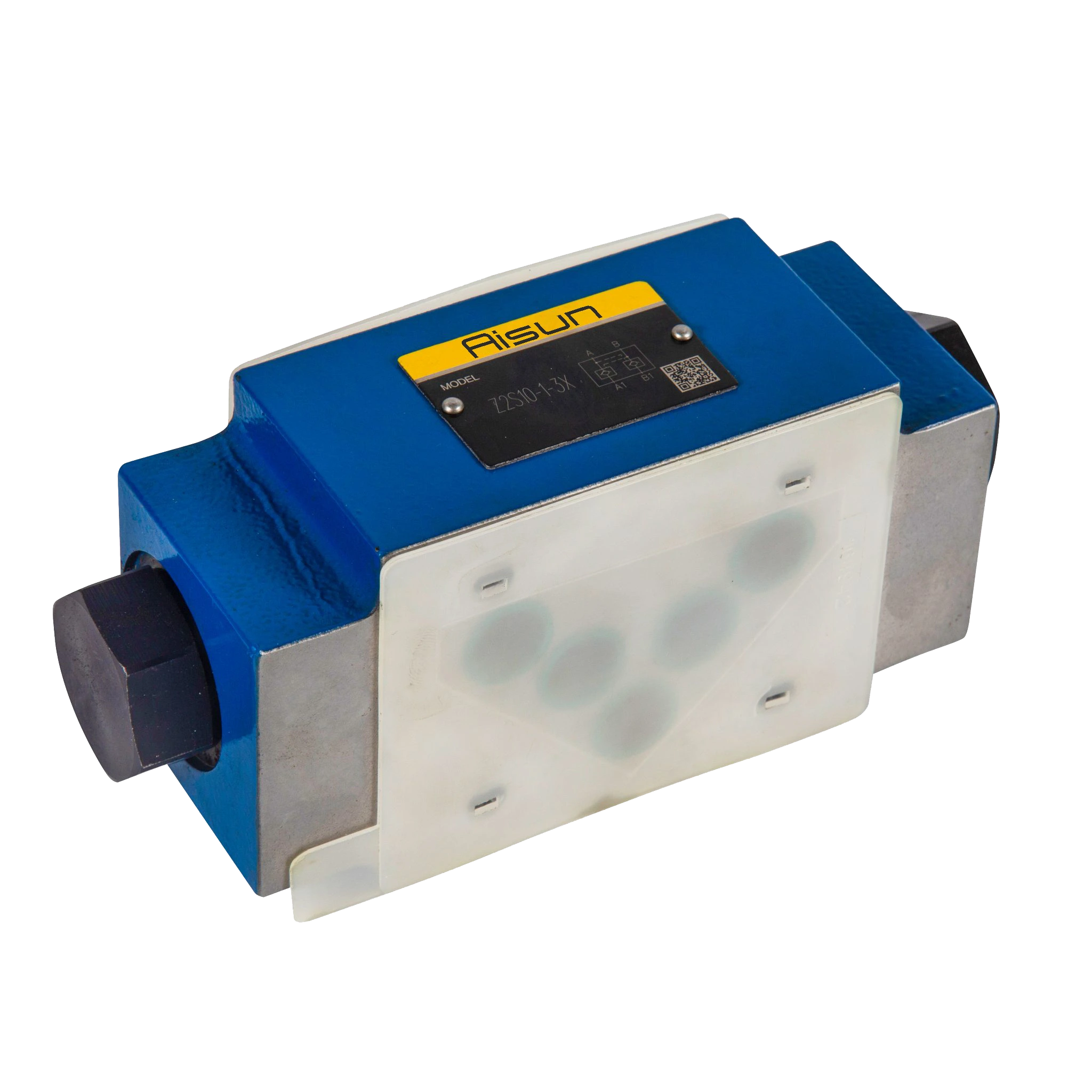

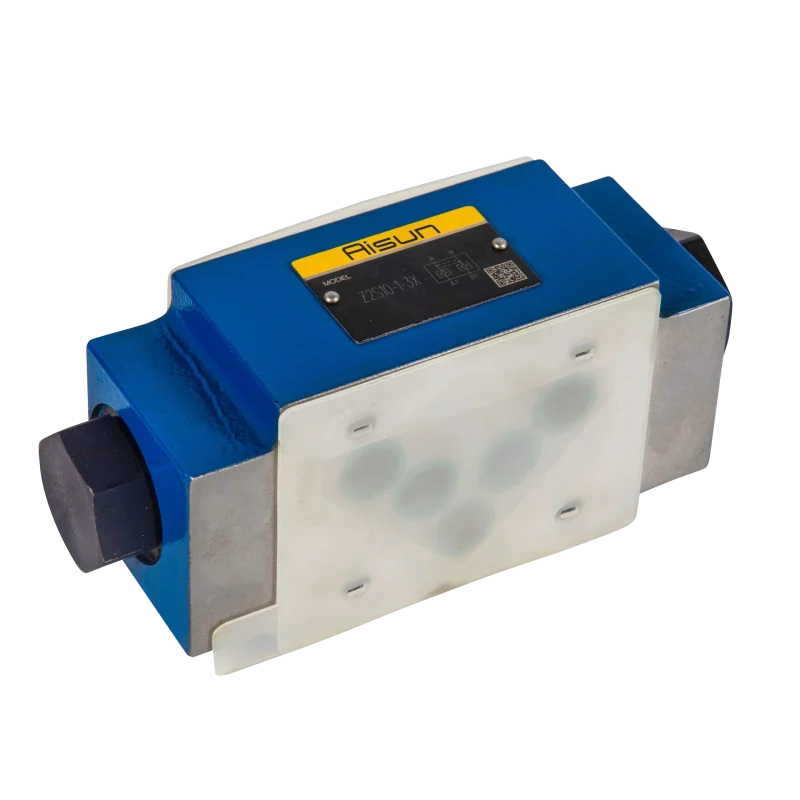

Modular check valve Z2FS

Modular check valve Z2FS

At its core, the Z2FS check valve operates as a double throttle check valve, boasting a stacked design that sets it apart from conventional counterparts. This design incorporates two throttle check valves symmetrically arranged to govern fluid flow meticulously. The primary objective of this valve is to limit the main flow or control the flow within one or two working oil ports, providing engineers with a versatile tool for managing hydraulic systems with precision.

In scenarios where meter-in control is imperative, the oil fluid follows a specific path from port A1 to A2 through the intricately designed throttle port(1). This port comprises the valve seat (2) and throttle spool (3), components that play a pivotal role in regulating the flow. The adjustability of the throttle spool (3) along its axis, facilitated by the adjusting screw (4), empowers operators to fine-tune throttle port(1) to achieve the desired flow characteristics. Upon the fluid’s return from the working oil port A2, the valve seat (2) opens against the force exerted by the spring (5). This ingenious mechanism transforms the valve into a check valve, allowing for unrestricted free-flow in the opposite direction. The flexibility to configure the valve for meter-in or meter-out control, depending on its installation position, further amplifies its utility in diverse hydraulic applications.