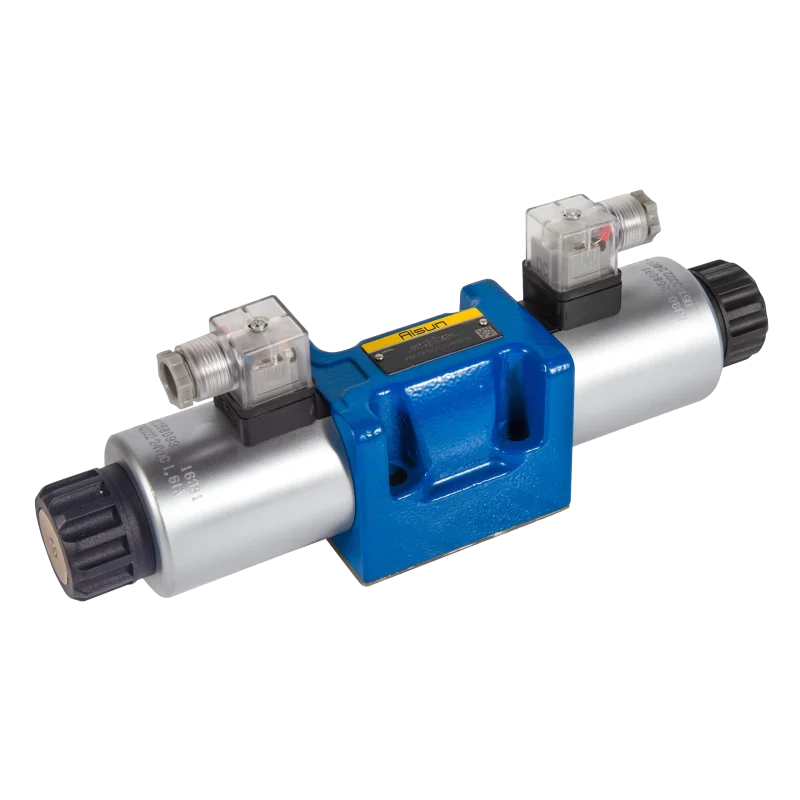

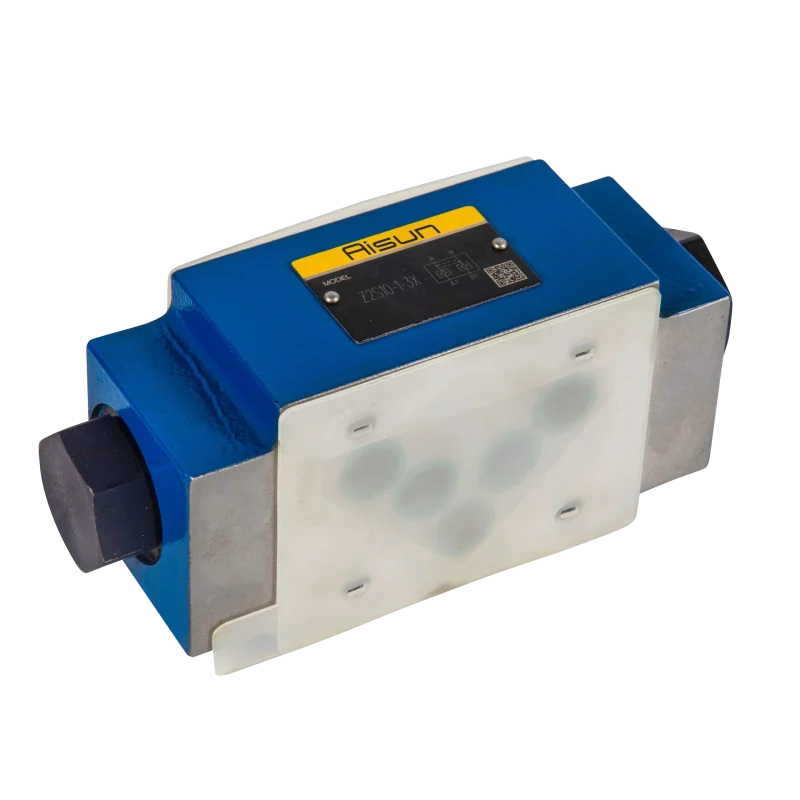

Flow control valve DV

A DV (Directional Regulating Valve) is a type of hydraulic flow control valve used to regulate the flow of hydraulic fluid in a hydraulic circuit while controlling the direction of the fluid as well. These valves are designed to ensure smooth operation and prevent problems such as over-speeding of hydraulic actuators (like cylinders or motors) by maintaining a steady and controlled flow.

The DRV valve typically refers to a directional flow control valve that combines both directional control and flow regulation within a single valve. This type of valve plays an important role in ensuring that hydraulic actuators, such as cylinders or hydraulic motors, move in a controlled manner with a consistent speed.

Key Features of DV Hydraulic Flow Control Valve:

- Flow Regulation: The DRV valve controls the flow rate of the hydraulic fluid going to the actuator, which directly impacts the speed at which the actuator moves. The flow can be adjusted to ensure that the hydraulic system functions at the desired speed, helping to prevent excessive speeds or unsafe operations.

- Directional Control: In addition to flow regulation, the DRV valve is capable of controlling the direction of fluid flow. This means that the valve can direct the fluid either to extend or retract a hydraulic cylinder, or to rotate the motor in one direction or the other.

- Pressure Compensation (in some models): Some DRV valves are pressure-compensated, meaning that they adjust the flow rate to maintain a consistent output even under changing load pressures. This ensures that the actuator moves at a steady speed, regardless of the load variation. It compensates for the pressure increase that can occur as the load increases, maintaining the pre-set flow rate.

- Type of Actuation: The DRV valve can be actuated either manually (via a lever or knob) or electrically (via solenoids or motors), depending on the specific design of the valve and the application requirements. This provides flexibility in how the valve is controlled within a hydraulic system.

- Bidirectional Flow: In many applications, the DRV valve can control fluid flow in both directions. For example, in a double-acting hydraulic cylinder, the valve will regulate the flow of fluid both when the cylinder is extending and retracting, thus controlling the speed of movement in both directions.

- Safety and Efficiency: The DRV valve prevents flow that could be unsafe or lead to issues such as excessive cylinder speed or pressure. By controlling the rate of flow to hydraulic actuators, it helps prevent damage from over-speeding and ensures smooth and efficient operation.

How Does the DV Hydraulic Flow Control Valve Work?

The DV valve regulates both the flow rate and direction of the hydraulic fluid as follows:

- Flow Control: When the valve is in operation, the flow rate can be adjusted, either manually or automatically, depending on the system design. The valve constricts or opens an orifice to regulate the volume of fluid allowed to pass through.

- Directional Control: The valve controls the direction of fluid flow to the actuator (e.g., cylinder or motor). This allows the actuator to either extend or retract, or the motor to rotate in the desired direction.

- Pressure Compensation (if applicable): In pressure-compensated models, as the load pressure changes, the valve compensates to maintain the same flow rate to the actuator, ensuring that the speed of the actuator remains constant.

- Actuation: The valve can be operated by a manual lever (in simple systems), or electrically (in more complex systems), where the actuation of the valve determines the direction and the amount of flow delivered to the actuator.

Applications of DV Flow Control Valves:

The DRV valve is used in hydraulic systems where precise control of both flow and direction is necessary. Common applications include:

- Hydraulic Cylinders:

- Speed Control: The DRV valve is widely used to control the speed of hydraulic cylinders. By regulating the flow of fluid to the cylinder, the valve controls how fast or slow the cylinder extends or retracts.

- Double-Acting Cylinders: It can regulate the flow in both directions, controlling the speed of the cylinder during both extension and retraction.

- Hydraulic Motors:

- It is used in motor circuits to regulate the speed and direction of hydraulic motors. In mobile equipment such as excavators or cranes, the DRV valve can control the rotation speed of the motor, ensuring precise movement.

- Mobile Equipment:

- Commonly found in construction machinery, agricultural equipment, and material handling equipment, the DRV valve ensures that hydraulic actuators, such as arms, booms, or lifts, move at a controlled and desired speed.

- Industrial Machinery:

- In manufacturing systems that involve hydraulic presses, clamping, or automated machinery, DRV valves regulate the speed and movement of hydraulic actuators to ensure accuracy and efficiency.

- Pressure Systems:

- In hydraulic systems that require precise pressure regulation and compensation, DRV valves are used to maintain consistent flow rates while adapting to varying pressures in the system.

Advantages of the DV Hydraulic Flow Control Valve:

- Precise Control: It provides precise control over the speed and direction of hydraulic actuators, ensuring smooth and predictable operation.

- Safety: By controlling flow and pressure, DRV valves protect against over-speeding or excessive pressure that could damage components or reduce system efficiency.

- Improved System Performance: It enhances the performance of hydraulic systems by maintaining consistent flow rates and system pressure, especially in applications with varying loads.

- Versatility: DRV valves are highly versatile and can be used in a variety of applications, including simple and complex hydraulic circuits.

- Pressure Compensation: In systems that experience load variation, the pressure-compensated DRV valve maintains consistent flow, improving the reliability and stability of the system.

Considerations When Using DV Flow Control Valves:

- Size and Flow Rate Matching: The DRV valve must be properly sized to the hydraulic system’s flow rate and pressure requirements to ensure effective performance.

- Maintenance: Like all hydraulic components, DRV valves require regular inspection and maintenance to ensure they are operating correctly. This may include cleaning, checking seals, and verifying the adjustment of flow settings.

- Pressure Settings: Careful consideration should be given to the valve’s pressure settings to ensure that it functions correctly and does not cause excessive pressure drop or inefficiency in the system.

- System Compatibility: Ensure that the DRV valve is compatible with other components in the hydraulic circuit, including the pump, actuators, and any other control valves.

Conclusion:

The DV hydraulic flow control valve is an essential component for regulating both the flow rate and direction of fluid in hydraulic systems. It provides precise control of actuator speed and direction, prevents over-speeding, and ensures safe and efficient operation. The versatility of the DRV valve makes it suitable for a wide range of applications, from industrial machinery to mobile equipment. By combining flow control and directional regulation, it ensures that hydraulic systems operate smoothly, reliably, and safely, even under varying load conditions.

Flow control valve DV

Flow control valve DV

The DV(P)/DRV(P) type flow valves, also known as (Check) Restrictor Valves, are essential flow control valves in hydraulic systems. These valves are specifically designed to regulate the speed of actuators with precision and simplicity. Additionally, they can function as shut-off valves when fully closed, adding to their versatility in hydraulic applications.

The design of the DV(P)/DRV(P) Flow back valves includes a triangular scale that visually represents the flow adjustment. The size of the triangle on the valve scale corresponds to the flow rate, providing a quick and intuitive way to assess the fluid flow magnitude. This visual cue is crucial for operators and system engineers to accurately gauge and control hydraulic flow.