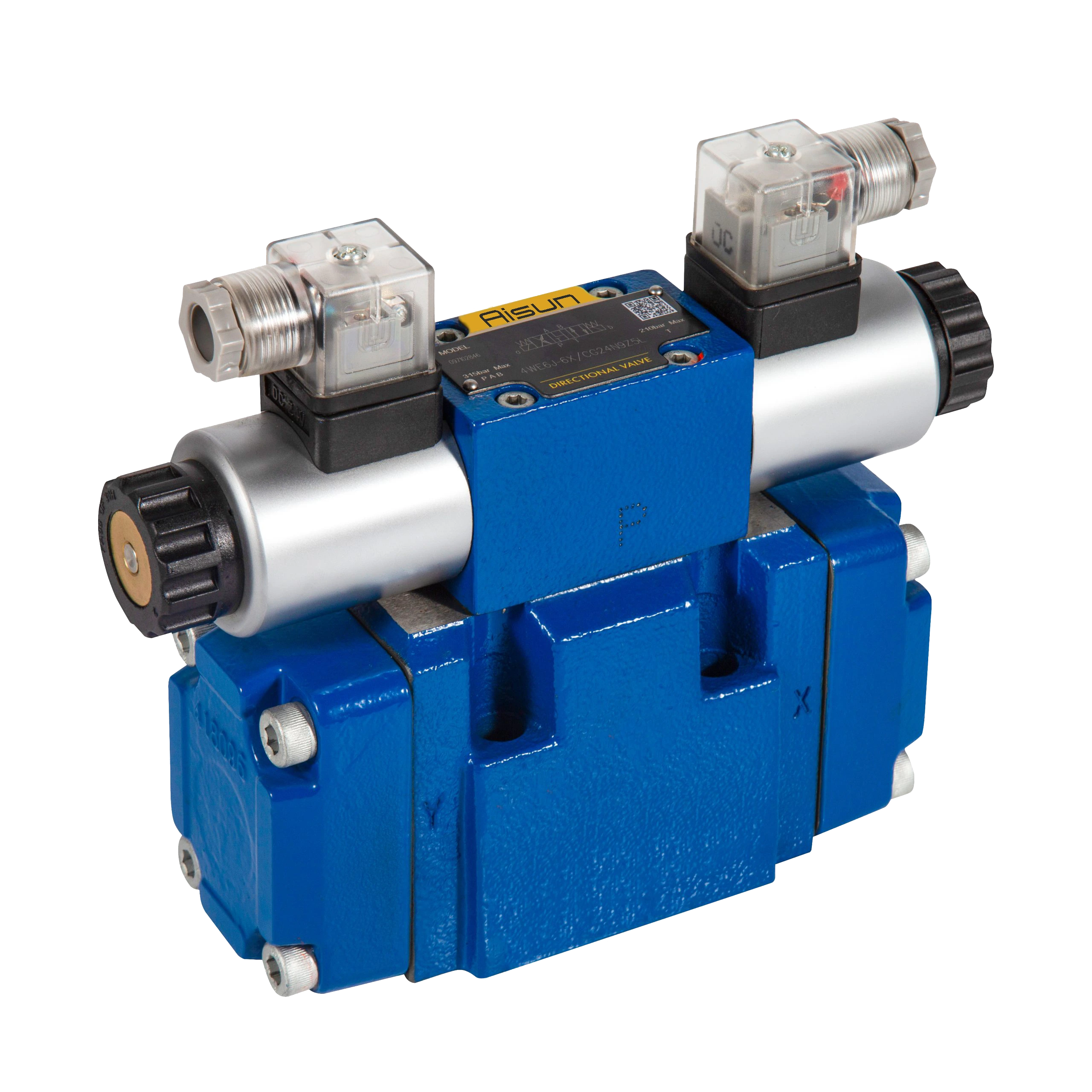

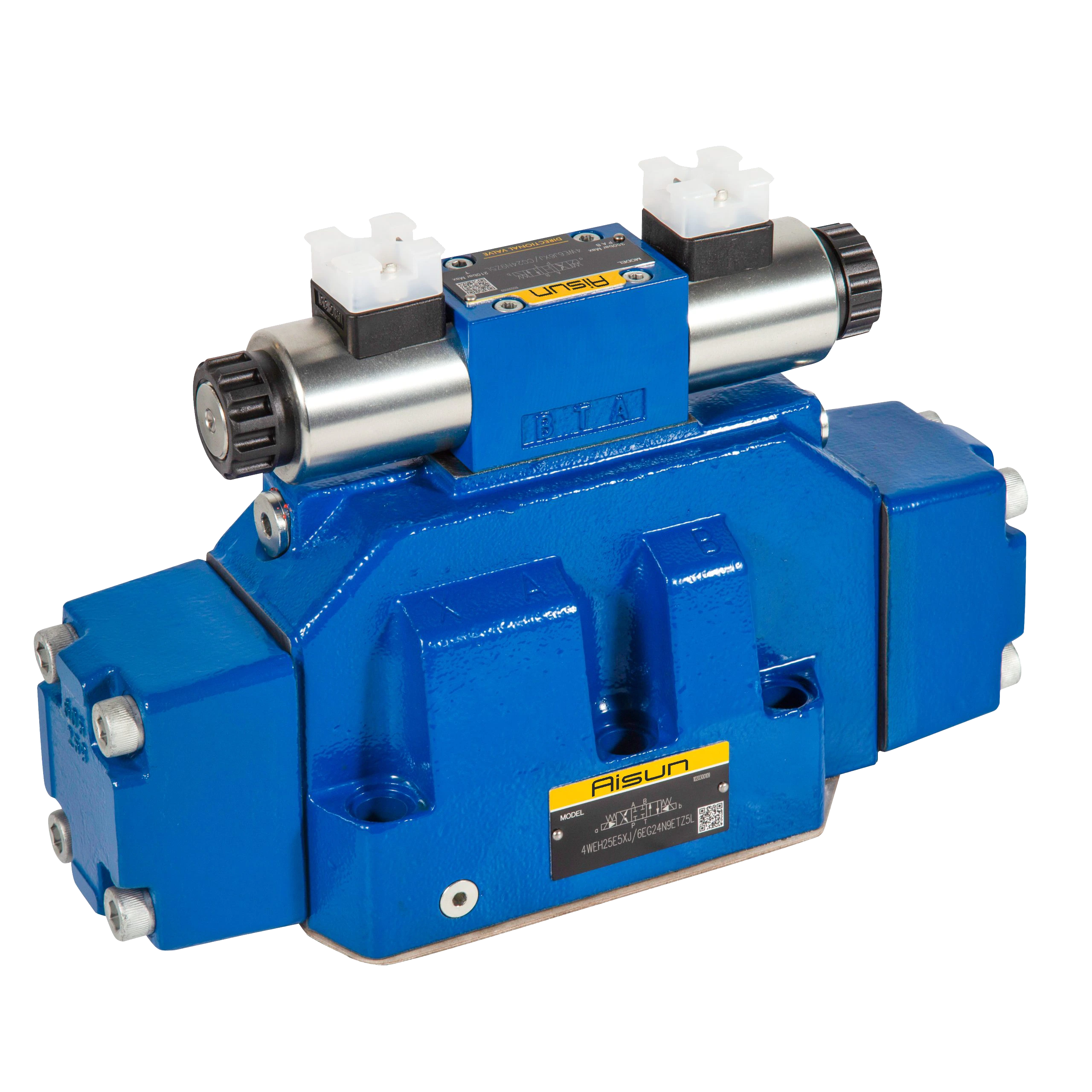

Hydraulic Directional Valve 4WEH

The 4WEH hydraulic directional valve is a specific type of electrohydraulic directional control valve commonly used in hydraulic systems to control the direction and flow of fluid. The “4WEH” designation typically refers to a valve with four ports, electro-hydraulic operation, and a proportional control function. Below is an in-depth explanation of the 4WEH hydraulic directional valve:

Working Principle:

A 4WEH hydraulic directional valve works by controlling the flow of hydraulic fluid in a hydraulic circuit. The main function of this valve is to direct hydraulic fluid from the pressure port (P) to one of the actuator ports (A or B), and to return fluid to the tank (T) as needed. The valve’s internal spool, controlled by an electrical signal, shifts to alter the flow path.

• The valve is typically used for controlling the direction of movement of hydraulic actuators, such as cylinders or motors.

• The proportional nature of the valve means that the flow is not just an “on/off” function but can vary based on the strength of the electrical signal. For example, varying the voltage or current applied to the solenoid or actuator adjusts the position of the spool, and consequently, the flow rate to the actuator.

• In applications involving a double-acting cylinder, the valve can direct fluid to either side of the cylinder, allowing it to extend or retract, and the flow rate can be adjusted proportionally to control the speed of movement.

Features of the 4WEH Valve:

• Four Ports: The valve has four ports – one for the pressure supply (P), one for tank return (T), and two actuator ports (A and B).

• Electrohydraulic Actuation: The valve is controlled by an electrical signal, typically sent to a solenoid, which shifts the valve spool.

• Proportional Control: The valve’s proportional characteristic allows for smooth, variable flow regulation. The flow rate is proportional to the input electrical signal (usually voltage or current).

• High-Pressure Capability: The “H” indicates that the valve is designed for higher pressure applications and can withstand the pressure conditions in demanding hydraulic systems.

Types of 4WEH Valves:

There are different versions of 4WEH valves depending on the application requirements:

• Single or Double Solenoid: Some 4WEH valves may have a single solenoid for one-direction control or a double solenoid for bidirectional control.

• 3-Position vs. 2-Position: The valve may be available in 3-position (neutral, extend, retract) or 2-position configurations.

• Flow Ratings: These valves come in different flow rate sizes, such as 4WEH10 (indicating 10 L/min flow), 4WEH16, etc., depending on the capacity and application needs.

• Pressure Ratings: The valves are designed to handle different pressure levels, with the “H” suffix often signifying high-pressure handling.

Functionality in Hydraulic Systems:

• Direction Control: The primary function of the 4WEH valve is to direct fluid flow to the hydraulic actuators, determining their direction of movement.

• Speed Control: Because the valve is proportional, the flow rate is variable based on the electrical signal, which means the speed of the actuator (such as a cylinder) can be precisely controlled.

• Actuator Control: It is widely used to control double-acting cylinders (extend/retract) and hydraulic motors (forward/reverse) in applications such as mobile machinery, industrial equipment, and manufacturing systems.

Applications:

The 4WEH hydraulic directional valve is used in various industries where directional control and proportional flow adjustment are required:

• Mobile Equipment: It is commonly used in construction machinery, agricultural equipment, and other mobile machines for precise control of actuators like hydraulic cylinders and motors.

• Industrial Machinery: Employed in automated machinery and systems, such as presses, lifts, and conveyors, to control the movement of hydraulic actuators.

•Material Handling: Used in equipment like forklifts, cranes, and lifts to manage the direction and speed of movement for material handling operations.

• Power Units and Hydraulic Systems: Often found in power units and hydraulic systems that require precise, proportional directional control.

Advantages of the 4WEH Valve:

• Precise Control: Due to its proportional nature, the 4WEH valve allows for fine control over the actuator’s speed and direction, ensuring smooth, predictable movement.

• Flexibility: The valve can be integrated into a wide variety of hydraulic systems, making it suitable for different types of equipment and operations.

• Electrohydraulic Actuation: The electrical control allows for easy integration into automated control systems, enabling remote operation and digital control.

• High-Pressure Performance: The “H” in the designation indicates that the valve is built to handle higher pressures, making it suitable for demanding industrial and mobile applications.

Considerations:

• Electrical Control Requirements: The valve requires an appropriate electrical control signal (voltage or current) to function properly. Ensuring compatibility with the control system is crucial for correct operation.

• Size and Flow Matching: It’s important to choose a valve with the correct flow capacity (e.g., 10 L/min, 16 L/min) and pressure rating to match the hydraulic system’s specifications for optimal performance.

• Maintenance: As with any hydraulic component, regular maintenance is necessary to ensure smooth operation, avoid wear, and maintain reliability under high-pressure conditions.

Conclusion:

The 4WEH hydraulic directional valve is a proportional, electro-hydraulic valve used for controlling the direction and flow of fluid in hydraulic systems. With its high-pressure handling capabilities and precise, variable flow control, it is ideal for applications requiring fine control of actuator movement, such as in mobile machinery, industrial equipment, and material handling systems. The electrohydraulic actuation offers flexibility for integration into automated control systems, making it a versatile component in modern hydraulic applications.

Electro-Hydraulic Directional Valves WEH

Electro-Hydraulic Directional Valves WEH

WEH Series – Electro-Hydraulic Directional Spool Valve: The WEH series represents a class of directional spool valves featuring Control Valve electro-hydraulic operation. These valves take command of the initiation, cessation, and direction of fluid flow within hydraulic circuits. The core components include the main valve body, main valve spool, one or two return springs, and the pilot valve equipped with one or two solenoids.

Features

- -Control Valve Electro-Hydraulic Operated

- – Valves used to control the start, stop and

- direction of a fluid flow

- – Electro-hydraulic operation (WEH)

- – Hydraulic operation (WH)

- – Subplate mounting

- porting pattern conforms to DIN24340 form A and ISO4401

- – Spring or pressure centered, spring or hydraulic offset

- – Wet pin DC or AC solenoids, optional

- – Hand override, optional

- – Electrical connection as an individual or

- central connection

- – Shifting time adjustment, optional

- – Pre-loading valve in the P-channel of the main valve, optional

- – Auxiliary equipment to data sheet

- – Stroke adjustment at main spool, optional

- – Stroke adjustment and/or end position indicator, optional

- Mechanical or inductive limit switch

- (proximity type) at the main spool