Features of the 4WEMM Directional Valve:

- 4-Way: The “4W” in the name indicates that the valve has four ports:

- P (Pressure): The inlet port that receives the pressurized fluid.

- T (Tank): The outlet port where the fluid returns to the tank or reservoir.

- A and B (Actuator Ports): These two ports are connected to the actuator (e.g., hydraulic cylinder or motor), allowing fluid to flow to the actuator to control its movement.

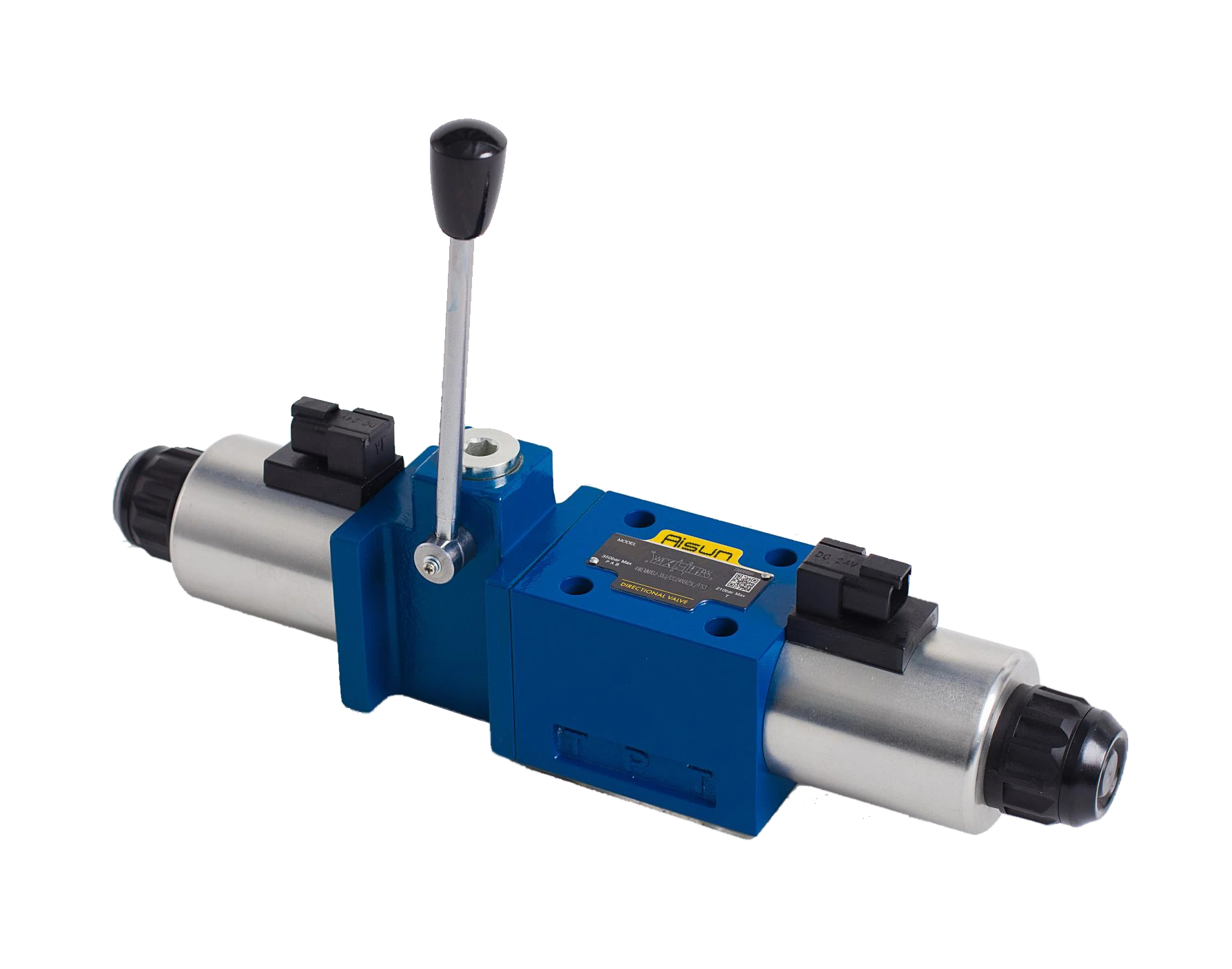

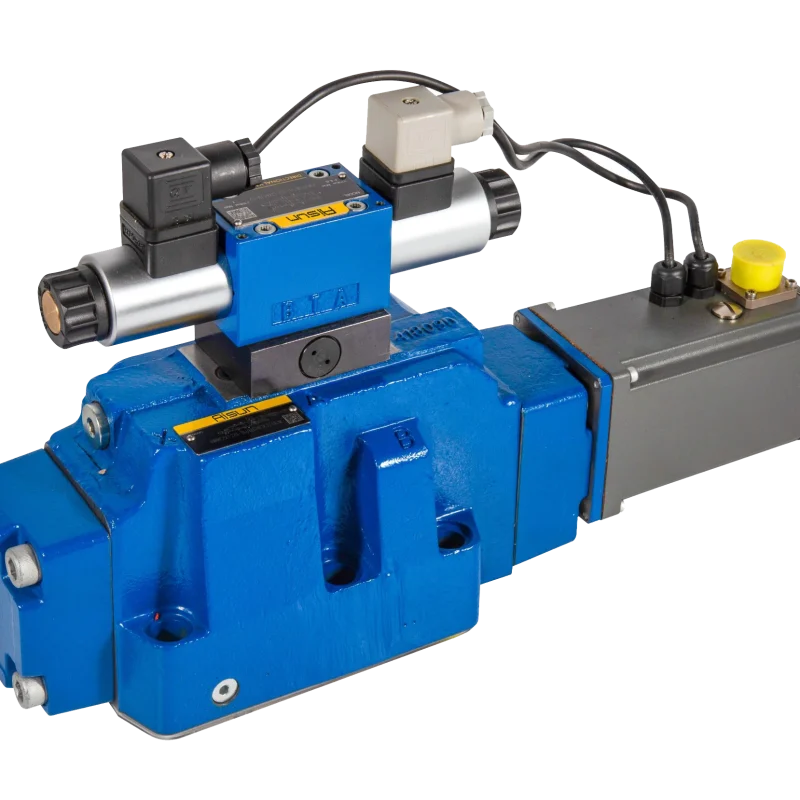

- EMM Series: The “EMM” refers to a specific series of valves within Aisan’s line, which generally indicates a modular valve design with options for electric or manual operation, depending on the application.

Operation of the 4WEMM Directional Valve:

The 4WEMM directional valve is designed to control the flow direction of hydraulic fluid through a system, enabling or blocking flow to different components based on the position of the valve spool. Here’s how it operates:

1. Ports and Flow Paths:

The 4WEMM directional valve typically has four key ports:

- P (Pressure): Fluid enters the valve from the pump.

- T (Tank/Return): Fluid returns to the tank after completing its work.

- A and B (Actuator Ports): These ports direct fluid to and from the hydraulic actuator (such as a hydraulic cylinder or motor).

The spool inside the valve determines how the fluid is routed to these ports.

2. Spool Movement:

- The spool is the main moving part inside the valve. It shifts between different positions, and each position corresponds to a different routing of fluid through the valve.

- The spool’s movement can be actuated manually (via a lever or handle), pneumatically (via air pressure), or electrically (via solenoids or motors).

3. Valve Positions:

The 4WEMM valve typically has several positions that correspond to different fluid flow paths. Common configurations are:

- 2-Position Valve: In the 2-position version, the valve has two distinct spool positions:

-

- Position 1 (Flow to A): The fluid from the P (Pressure) port is directed to the A port, causing the actuator to move in one direction (e.g., extend a hydraulic cylinder).

- Position 2 (Flow to B): The fluid is directed to the B port, causing the actuator to move in the opposite direction (e.g., retract the hydraulic cylinder).

- 3-Position Valve: The 3-position valve has three distinct positions:

-

- Position 1 (Flow to A): Fluid flows to port A, causing the actuator to extend.

- Position 2 (Neutral/Blocked): In this center position, fluid flow is blocked from both ports A and B, and the actuator stops moving. This position is commonly used to “hold” the actuator in place.

- Position 3 (Flow to B): Fluid flows to port B, causing the actuator to retract.

- 4-Position Valve: In the 4-position valve, the spool has four distinct positions, enabling more complex flow routing. These may include:

-

- Two flow directions to the actuator ports (A and B) for forward and reverse motion of the actuator.

- A neutral center position where both A and B ports are blocked.

- Additional configurations can allow the fluid to flow in more sophisticated patterns, such as simultaneous operation of two actuators or use of different flow rates.

4. Actuation Methods:

- The 4WEMM valve can be actuated in different ways:

- Electrically Actuated: The valve may be equipped with solenoids to shift the spool in one direction or another based on electrical control signals.

- Manual Actuation: A lever or hand-operated valve can be used to manually shift the spool.

- Pneumatic Actuation: In some versions, the spool is shifted by compressed air, which provides a means for controlling the valve in automated systems.

The actuation controls the position of the spool, which in turn determines the flow paths and thus the direction of hydraulic fluid flow.

5. Flow Path Control:

The key function of the 4WEMM valve is to control how hydraulic fluid flows from the P (Pressure) port to the A and B actuator ports. Here’s how it works:

- Flow to A: When the spool is positioned to allow flow to port A, hydraulic fluid moves from the pump to port A, causing the actuator to extend or move in a certain direction.

- Flow to B: When the spool is shifted to direct flow to port B, the actuator moves in the opposite direction (e.g., retracts).

- Neutral/Center Position: In some configurations, the valve may have a neutral position where no flow reaches ports A and B, effectively “holding” the actuator in place. This is particularly useful for applications where the actuator must stay in a fixed position when not moving.

In more advanced configurations, the 4-position valve allows for simultaneous or alternate control of multiple actuators.

6. Typical Applications:

The 4WEMM directional valve is used in various applications where precise control of hydraulic actuators is needed. Some common uses include:

- Industrial Machinery: Used in presses, lifts, and machine tools to control hydraulic actuators that perform specific tasks.

- Mobile Equipment: Found in construction and agricultural machinery like excavators, cranes, tractors, and loaders to control hydraulic cylinders or motors for various movements.

- Hydraulic Power Units: Used in systems where a central power unit needs to distribute hydraulic fluid to various tools or actuators.

- Automation Systems: In automated systems, the valve can direct hydraulic fluid to different actuators based on sensors or programmable logic.

7. Performance Features:

- Flow Capacity: The valve is typically designed to handle high flow rates, ranging from 10 L/min to 400 L/min or more, depending on the model and application.

- Pressure Rating: The 4WEMM directional valve can handle system pressures up to 350 bar (5000 psi) or more, depending on the version.

- Leakage Prevention: The valve is designed to minimize internal leakage, especially in the neutral or center position, ensuring efficient performance and energy conservation.

- Compact Design: The valve typically has a modular, compact design that is easy to integrate into a variety of hydraulic circuits.

Conclusion:

The 4WEMM directional valve is an essential component in hydraulic systems, providing precise control over the flow of hydraulic fluid to actuators. By shifting the valve spool between different positions, it determines whether fluid flows to port A or B, controlling the direction of actuator movement. The valve can be actuated by electrical, manual, or pneumatic means, making it suitable for a wide range of applications, from industrial machinery to mobile equipment. The flexibility, performance, and reliability of the 4WEMM valve make it a popular choice for controlling complex hydraulic systems.

Directional spool valves 4WEMM

Directional spool valves 4WEMM

Applications in Hydraulic Systems: WEMM type directional spool valves find applications in scenarios where manual actuation is essential, especially during emergencies. The combination of solenoid operation and auxiliary handle control provides flexibility in fluid flow control, catering to diverse hydraulic system requirements.

In conclusion, the WEMM type directional spool valves represent a crucial advancement in hydraulic engineering, offering precise control with both solenoid and manual actuation options. Their versatile design and applications make them indispensable components in hydraulic systems, ensuring reliable performance and emergency response capabilities. As technology continues to evolve, these valves play a vital role in enhancing the efficiency and adaptability of hydraulic systems across various industries. Engineers and practitioners must grasp the intricacies of WEMM type valves to harness their full potential and contribute to the evolving landscape of hydraulic technology.