Directional Solenoid Valve 4we

A 4WE hydraulic directional valve is a specific type of valve used in hydraulic systems to control the direction of the fluid flow. The “4WE” designation typically refers to a 4-port, electrohydraulic directional control valve that is used for controlling the direction of movement of actuators like hydraulic cylinders and motors. Here’s an in-depth explanation of the 4WE hydraulic directional valve:

- 4WE Valve Overview:

- “4”: This indicates that the valve has four ports. These ports are used to control the flow of hydraulic fluid in various directions.

- P: The pressure port (input).

- T: The tank or return port (output).

- A and B: The actuator ports (to direct the flow of fluid to hydraulic cylinders or motors).

- “W”: The “W” in the designation stands for the work function or the specific type of valve. In the case of 4WE, the valve is typically a proportional valve that controls the flow of fluid proportionally based on an input signal (usually electrical).

- “E”: This refers to the electro-hydraulic actuation of the valve, meaning the valve is controlled using an electrical signal (such as from a solenoid or an electric motor) which actuates the valve spool, controlling the hydraulic fluid flow.

-

Function of the 4WE Directional Valve:

The 4WE directional valve is primarily used to control the direction of flow in a hydraulic system. By shifting the valve spool in one direction or another, it allows the hydraulic fluid to flow between the appropriate ports, directing the fluid to the correct actuator or hydraulic circuit.

- The valve typically controls a double-acting cylinder or a hydraulic motor, switching the direction of movement between extend/retract or forward/reverse, depending on the application.

- The valve works by having an internal spool that moves in response to an electrical signal (sent to a solenoid or motor). The position of the spool determines whether fluid is directed to port A or B, or possibly directed back to the tank through T.

- Working Principle:

- When an electrical signal is applied to the solenoid or actuator, the spool inside the valve moves from its neutral position. This movement of the spool redirects hydraulic fluid from the P (pressure) port to either the A or B port.

- When the spool shifts, fluid can flow into the actuator (such as a cylinder), causing it to move in one direction (e.g., extend or retract). Reversing the spool direction allows the fluid to flow to the opposite side of the actuator, thus reversing its movement.

The flow can be adjusted proportionally, meaning the speed of the actuator can be varied depending on the amount of current applied to the solenoid, making the 4WE valve a proportional directional control valve.

- Types of 4WE Valves:

The 4WE valve is available in several different versions, depending on the number of positions and types of control:

- 4WE10, 4WE6: These numbers indicate the different flow capacities or sizes of the valve, where 10, 6 refers to the flow rate capacity of the valve in liters per minute (L/min).

- 4WE6, 4WE10: Similar designations but typically used for smaller flow rate applications.

- 2-position vs. 3-position: Some versions of the 4WE valve have a 2-position spool (meaning it has two possible states: one for directing fluid in one direction and the other for reversing the flow). Others have 3 positions, which include a neutral or center position (where the valve is in a rest position with no flow), used in applications where holding a position is necessary.

- Proportional vs. On/Off: While the 4WE valve is commonly a proportional valve, which adjusts flow based on the control signal, there are versions with on/off control as well, where the valve simply switches the flow on or off based on the input signal.

- Common Applications:

The 4WE hydraulic directional valve is used in various applications where fluid direction needs to be controlled in hydraulic systems. These include:

- Mobile Equipment: In machines such as excavators, cranes, and agricultural machinery, where precise control of hydraulic actuators (e.g., cylinders, motors) is required.

- Industrial Machinery: Used in automated systems for controlling cylinders or motors in manufacturing processes.

- Construction: In equipment such as backhoes, bulldozers, and forklifts for controlling the direction and movement of hydraulic systems.

- Material Handling: In systems requiring directional control for lifting or transporting goods, such as in lifts, conveyors, and presses.

- Key Advantages:

- Precise Control: Proportional control allows for smooth, precise regulation of flow and speed of actuators.

- Versatility: Can be used in a wide range of hydraulic systems and applications, from simple to complex setups.

- Electro-hydraulic Control: The electrical control allows for remote or automated operation, making it easier to integrate into modern control systems.

- Key Considerations:

- Size and Flow Rate: Choosing the right size of the valve based on the flow rate needed for the application is crucial for efficient operation.

- Control Signal: The electrical control signal (voltage or current) must be matched to the valve’s specifications to ensure proper operation.

- Pressure Rating: The valve’s pressure rating must align with the system’s maximum working pressure to ensure safety and reliability.

In summary, a 4WE hydraulic directional valve is a versatile and widely used component in hydraulic systems for controlling the direction of flow to actuators. Its ability to be electrically controlled and adjusted proportionally makes it ideal for applications requiring precise movement and flow control.

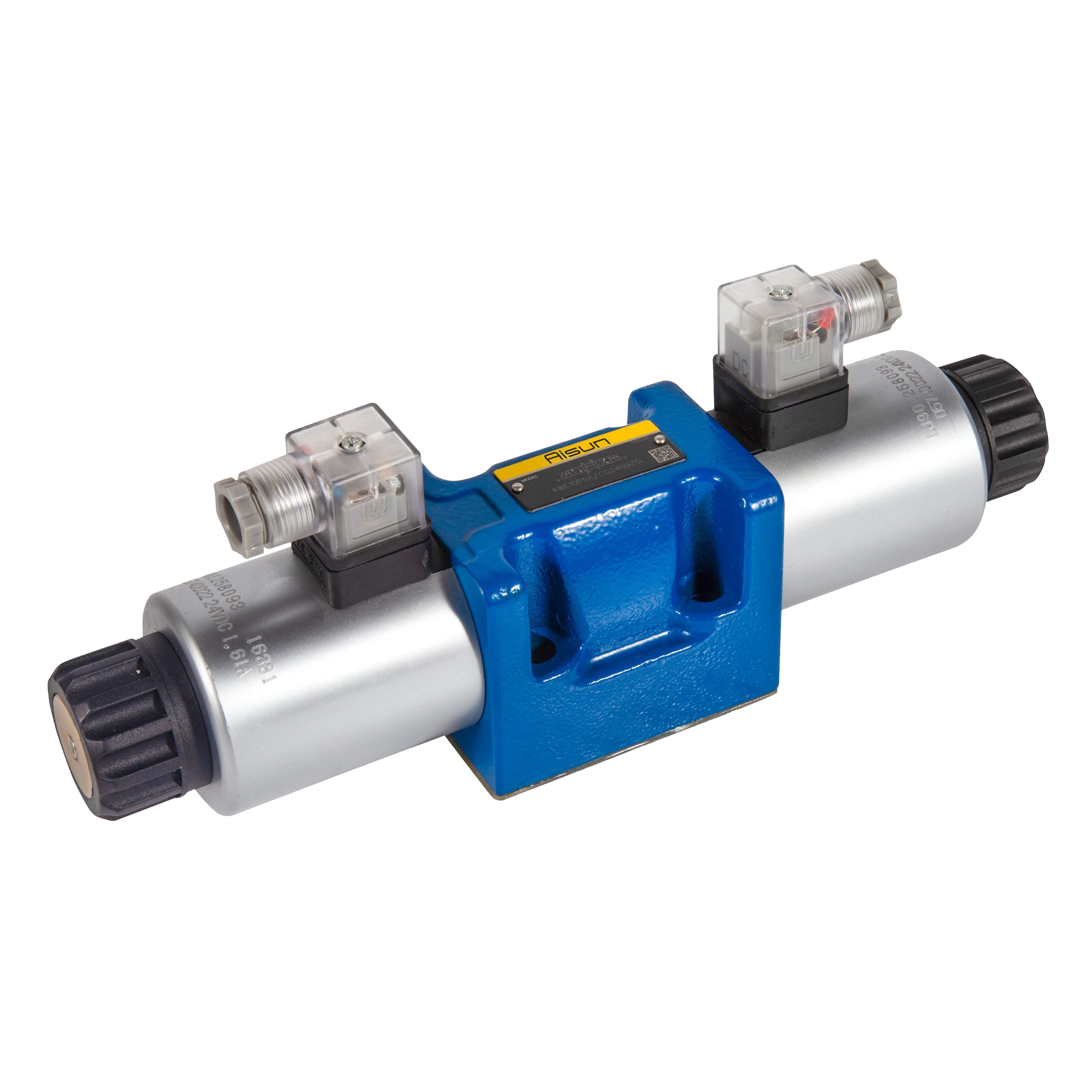

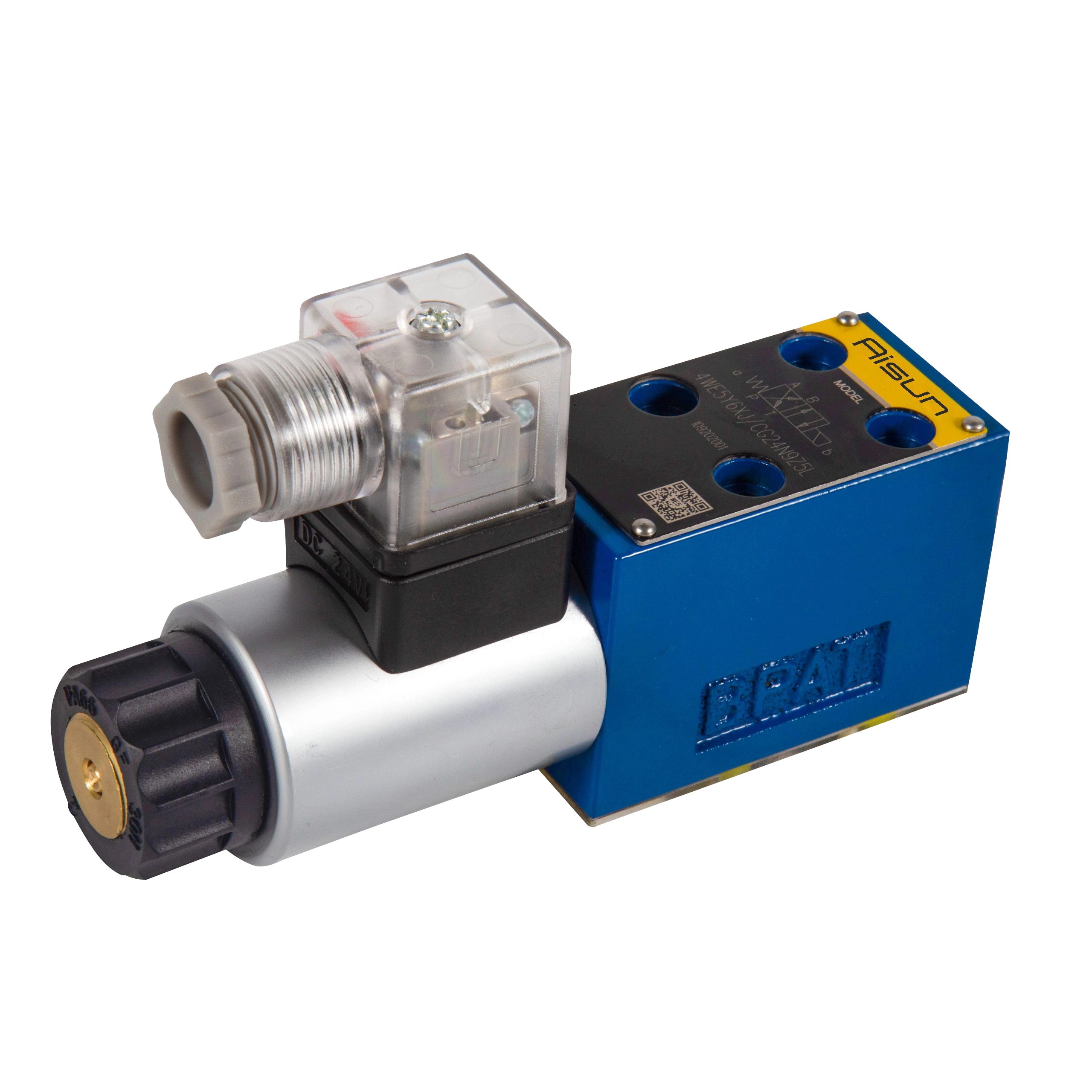

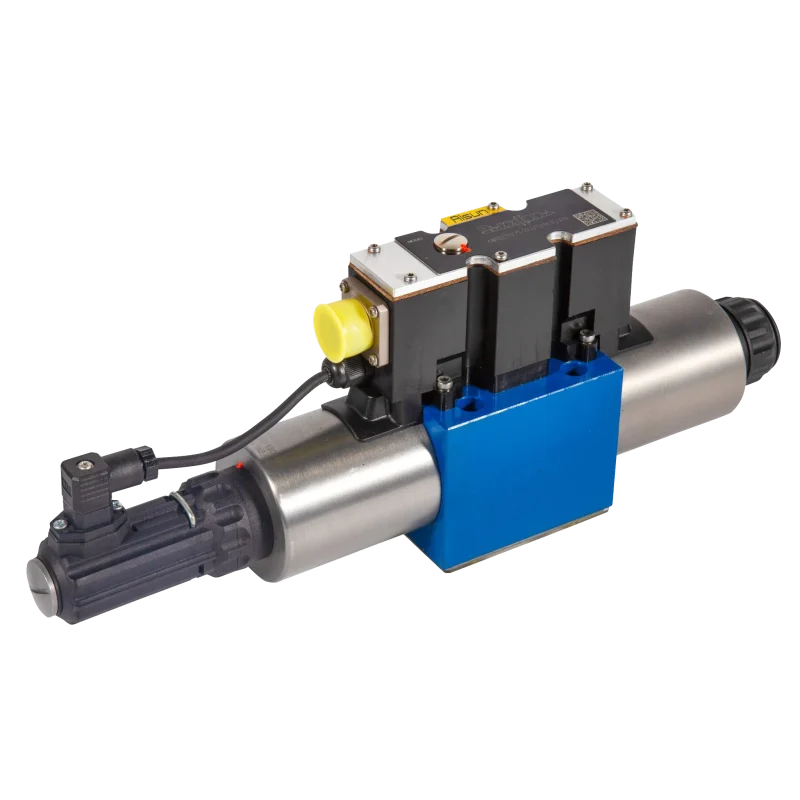

Directional Solenoid Valve 4we

Directional Solenoid Valve 4we

The 4WE Hydraulic Solenoid Directional Valve is a directional spool valve operated by the solenoid. It controls the opening, closing, and flow direction of the liquid flow. Features:

With the direct type solenoid operated directional spool valve as the standard type

Wet-pin DC or AC solenoids with detachable coil

The solenoid can be rotated by 90°

Replace the coil without releasing the oil

Individual or central electrical connection, optional

Optional manual emergency operation

The control input device of the Hydraulic Solenoid Directional Valve is a switching electromagnet, and the thrust generated when the electromagnet is energized makes the valve core do relative movement in the valve body to realize the reversing. The control signal of the solenoid valve can be directly controlled by the signal sent by the button switch, the stroke switch, the pressure relay and other components, and can also be controlled by the signal sent by the computer, the programmable controller and other control devices, which is convenient and widely used.