-

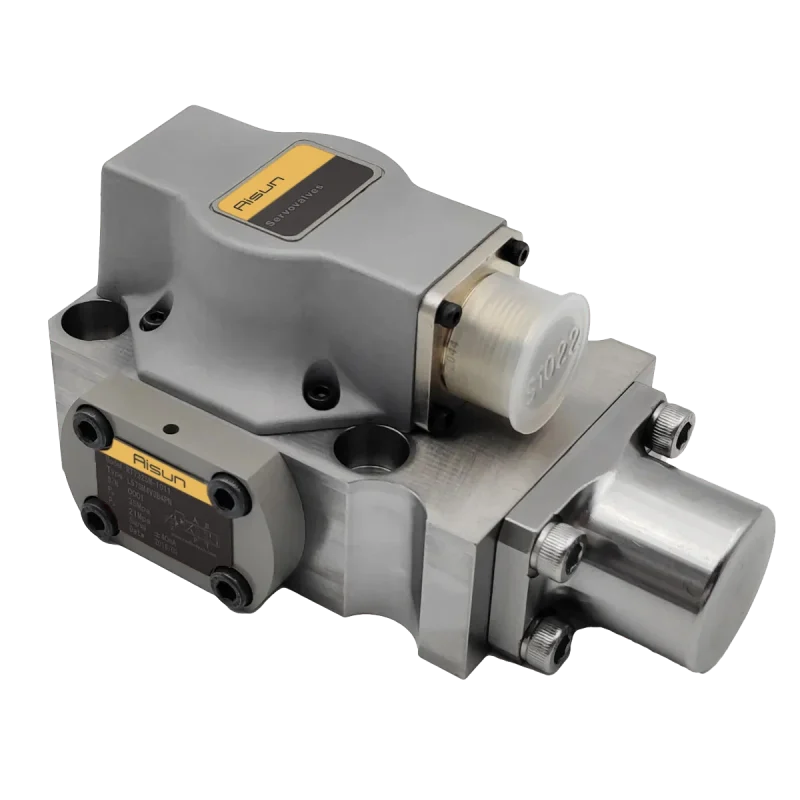

hydraulic Proportional Directional valves 4WRPEH

Price range: $1.374 through $1.702Proportional Directional valves 4WRPEH

The 4WRPEH high-response Proportional Directional Servo Valve, showcasing the advanced 4WRPEH6 variant, represents a remarkable achievement in fluid control systems. This pilot-operated directional control valve combines cutting-edge technology with precise construction elements to achieve unparalleled operational efficiency.

- Proportional Directional Servo Valve

- With control spool and sleeve in servo quality

- Operated on one side, 4/4-fail-safe position in switched off state

- Electric position feedback and integrated

- electronics(OBE), calibrated in the factory

- Electrical connection 6P+PE signal input differential amplifier with interface’ ‘A1″:土10V or interface’ ‘F1″: 4..20mA (Rsh =2000)

- Subplate mounting

- porting pattern to ISO 4401-03-02

-

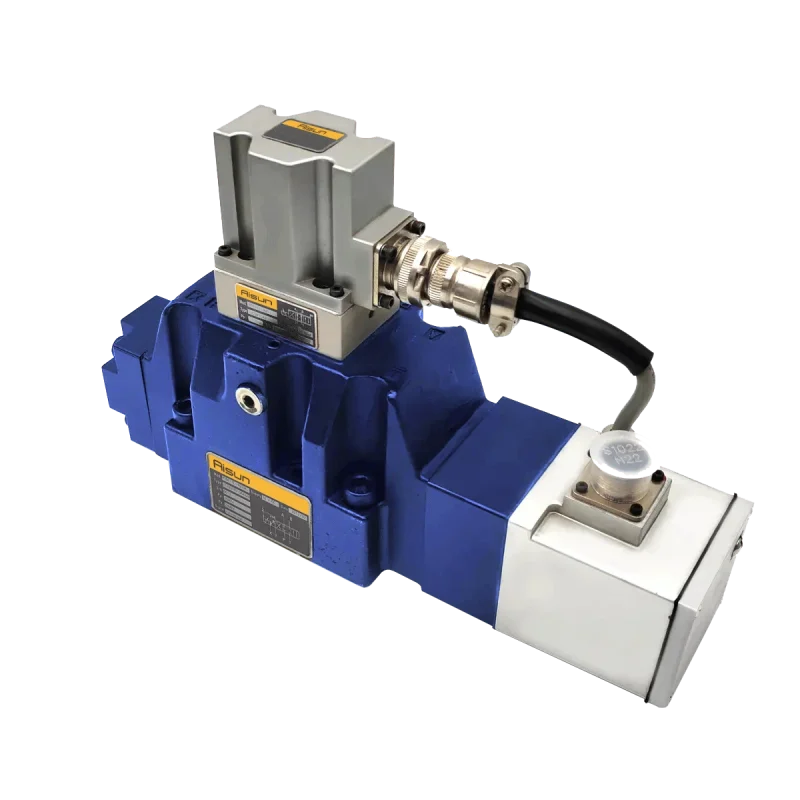

hydraulic Servo Directional valves 730 Series

Original price was: $4.226.$4.141Current price is: $4.141.Servo Directional valves 730 Series

Servo Directional valves 730 Series are a type of high-performance, precision valve used in hydraulic control systems. They are designed to control fluid flow in response to electrical input signals, providing fine, proportional control over hydraulic actuators like cylinders or motors. These valves are essential in applications that require accurate motion or position control, fast response times, and reliable performance in demanding environments. The Servo Directional valves 730 Series are typically used in aerospace, industrial, and other precision-driven applications.

-

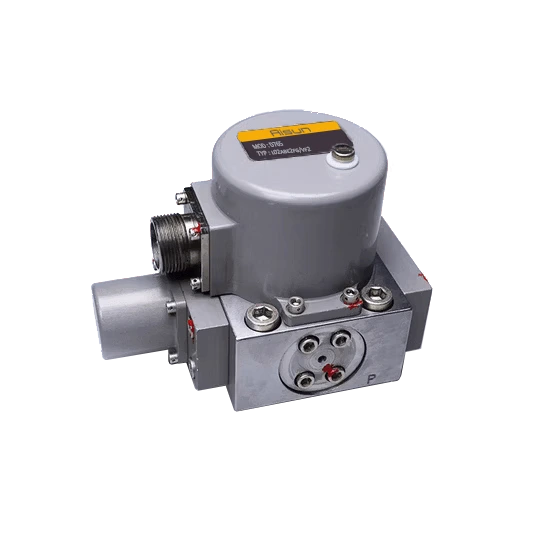

hydraulic Servo Directional valves D660

Price range: $5.198 through $9.101Servo Directional valves D660

The Servo Directional valves D660 is a type of electro-hydraulic servo valve used in advanced hydraulic control systems. It is designed to offer high precision and high-performance control for regulating fluid flow, pressure, and direction in a wide range of industrial and mobile applications. The D660 series is primarily used in applications where extremely precise control of hydraulic actuators (such as hydraulic cylinders or motors) is critical. These applications can include aerospace, machine tools, automation systems, and high-precision hydraulic testing.

-

hydraulic Servo Directional valves D761

Original price was: $3.432.$3.312Current price is: $3.312.Servo Directional valves D761

The Servo Directional valves D761 is a precision valve commonly used in hydraulic control systems to regulate fluid flow in response to electrical input signals. It is part of the family of servo valves, which are designed to offer high-performance control in applications where precise motion or position control is required. These valves are used in a wide range of industries, including aerospace, industrial automation, robotics, and more.

-

hydraulic Servo Directional valves D765

Original price was: $7.016.$6.903Current price is: $6.903.Servo Directional valves D765

The Servo Directional valves D765 is a precision valve commonly used in hydraulic control systems to regulate fluid flow in response to electrical input signals. It is part of the family of servo valves, which are designed to offer high-performance control in applications where precise motion or position control is required. These valves are used in a wide range of industries, including aerospace, industrial automation, robotics, and more.

-

Modular Check Valve Z1S

Price range: $48 through $79Modular Check Valve Z1S

The Z1S type valve is a direct operated check valve with a modular structure. This check valve is closed without leakage in one direction and allows free flflow in the other direction.

The stroke of the conical spool (3) is limited by the spring seat (4). The spring (5) causes the conical spool(3) to close. When there is no flfluid flflows through the valve, the spring (5) holds the conical spool (3) inthe closed position.

Model Z1S10…3XJ/V (metal-sealed) This valve has a metallic seal between the conical spool (3) and the valve body (1). Therefore, it is,particularly suitable for condition of working pressure higher than 100bar and the flflow rate greater than 4m/s.

-

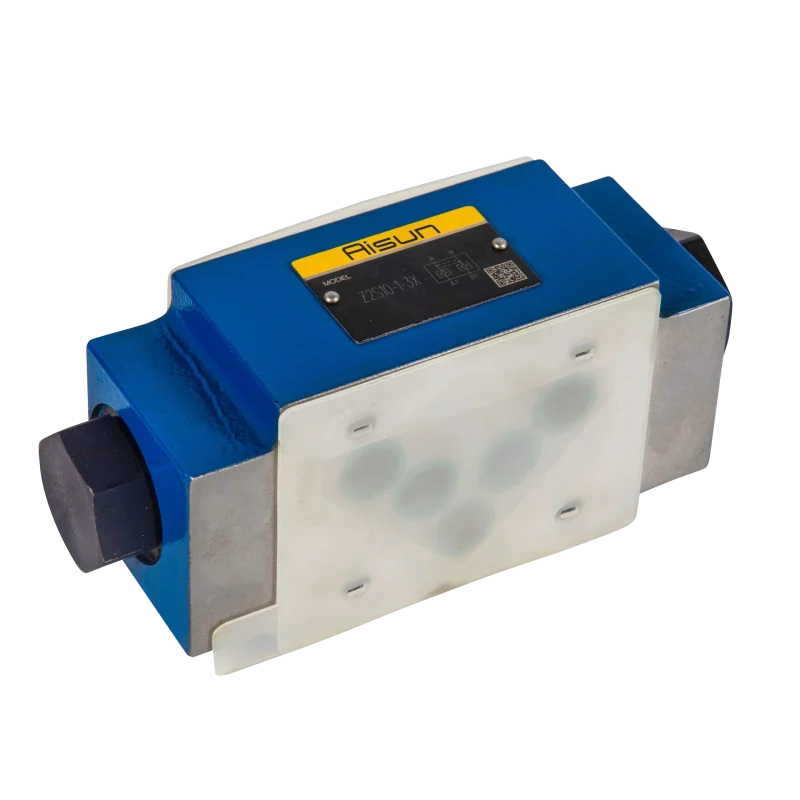

Modular check valve Z2FS

Price range: $59 through $348Modular check valve Z2FS

At its core, the Z2FS check valve operates as a double throttle check valve, boasting a stacked design that sets it apart from conventional counterparts. This design incorporates two throttle check valves symmetrically arranged to govern fluid flow meticulously. The primary objective of this valve is to limit the main flow or control the flow within one or two working oil ports, providing engineers with a versatile tool for managing hydraulic systems with precision.

In scenarios where meter-in control is imperative, the oil fluid follows a specific path from port A1 to A2 through the intricately designed throttle port(1). This port comprises the valve seat (2) and throttle spool (3), components that play a pivotal role in regulating the flow. The adjustability of the throttle spool (3) along its axis, facilitated by the adjusting screw (4), empowers operators to fine-tune throttle port(1) to achieve the desired flow characteristics. Upon the fluid’s return from the working oil port A2, the valve seat (2) opens against the force exerted by the spring (5). This ingenious mechanism transforms the valve into a check valve, allowing for unrestricted free-flow in the opposite direction. The flexibility to configure the valve for meter-in or meter-out control, depending on its installation position, further amplifies its utility in diverse hydraulic applications.

-

Modular Check Valve Z2S

Price range: $9 through $232Modular Check Valve Z2S

In the realm of hydraulic systems, precision control and reliability are paramount. The Z2S type modular hydraulic operated check valve emerges as a pivotal component in this landscape, featuring a sandwich plate design and excelling in providing leakage-free closure for one or two actuator ports, even during extended standstill periods. This article aims to unravel the intricate workings of the Z2S6 valve, shedding light on its design principles, operational mechanisms, and applications within hydraulic systems.

The Z2S6 valve stands as a pilot-operated check valve, ingeniously crafted in a sandwich plate design. Its primary function is to ensure the seamless closure of actuator ports, preventing any undesired fluid flow during prolonged periods of inactivity. The valve allows for unimpeded fluid flow in the A1 to A2 or B1 to B2 direction, and conversely, it efficiently blocks flow in the opposite direction. -

Plug-in check valve M-SR

Price range: $80 through $240Plug-in check valve M-SR

The primary function of a check valve in a hydraulic system is to allow fluid to flow in one direction only while blocking the flow in the opposite direction.

When fluid enters through port p1, the pressure at p1 overcomes the pressure at port p2 acting on the valve core, along with the spring force and friction between the valve core and the valve body, pushing the valve core open and allowing fluid to flow from p1 to p2, achieving forward flow. Conversely, when pressure oil enters from port p2, the valve core is pressed tightly against the valve seat by the combined action of the liquid pressure at p2 and the spring force, blocking the fluid flow and achieving reverse flow cutoff.Features:

- Size 8 to 30

- Maximum working pressure 315 bar

- Maximum working flflow 400 L/min

- Insert into the manifolds blocks

- Reverse closing without leakage

- 6 optional cracking pressure

-

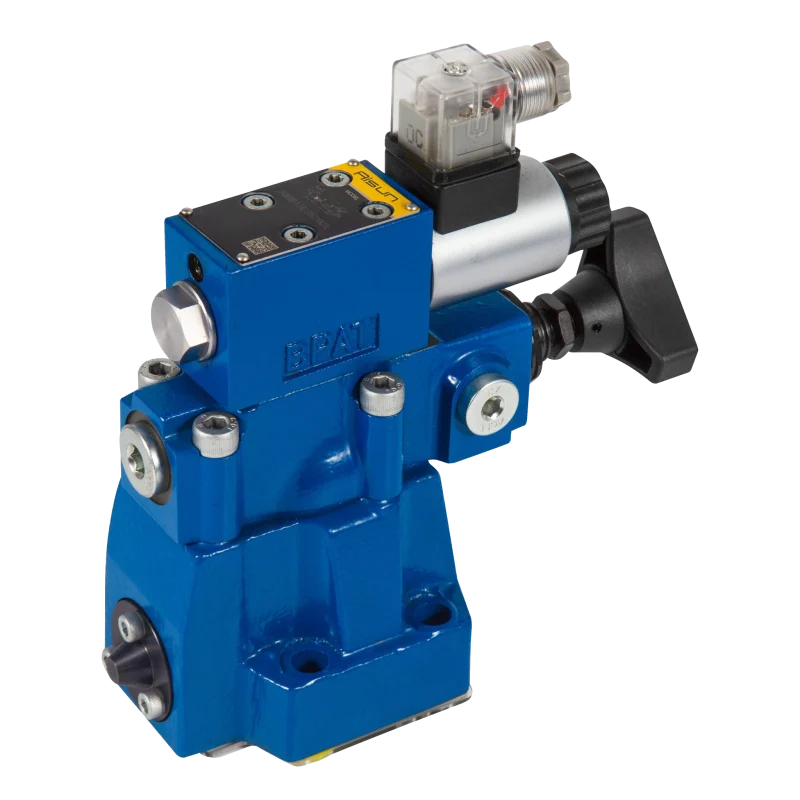

Pressure control valves DB and DBW

Price range: $138 through $285Pressure control valves DB and DBW

The DB and DBW pressure control valves are pilot operated relief valves.

They are used to limit (DB), or to limit and unload by solenoids (DBW) of working pressure.

- ◆ Size 10 to 32

- ◆ Maximum working pressure 350 bar

- ◆ Maximum working flow 650L/min

- ◆Subplate mounting: size 10/20/30

- ◆Threaded connection:size 10/15/20/25/32

- ◆Setting pressure:5MPa/10MPa/20MPa/31.5bar/35MPa

- ◆Flow rate:250L/min (for size 10 only),500L/min (for size 15, 20, 25),650L/min (for size 32 only)

-

Pressure relief valve DBD

Price range: $44 through $217Pressure relief valve DBD

The DBD hydraulic pressure relief valve is direct operated, it is used to limit the pressure of hydraulic system. Features:

- Inserted cartridge

- Threaded connection

- Subplate mounting

- 3 pressure adjustment elements

-Inner hexagon adjusting screw with -protective cap -Adjusting handle -Adjusting handle with lock

The DBD hydraulic pressure relief valve is a crucial component used to regulate and control the pressure in hydraulic systems. Its direct operation ensures efficient and accurate pressure limitation, preventing any potential damage or failure within the system.

-

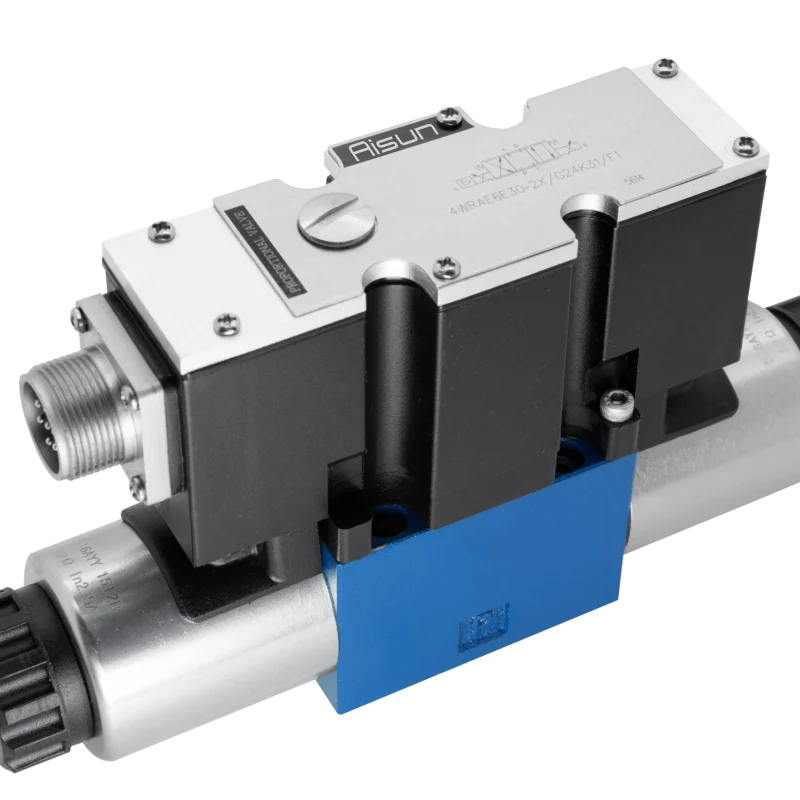

Proportional directional valves 4WRA

Price range: $424 through $1.081Proportional directional valves 4WRA

Proportional directional valves 4WRA are capable of controlling the direction and flow of the hydraulic system according to the polarity and amplitude of the input electrical signal, thus realising the control of the direction and speed of the movement of the actuating elements.

- Size 6 and 10

- Maximum working pressure 315 bar

- Maximum working flflow 42 L/min (size 6)

- 75 L/min (size 10)

- Proportional direction valve with direct operated proportional solenoid

- For subplate mounting

- Control the direction and flow

- Spring centred control spool

- Both valves and proportional amplififiers from the same supplier