-

Check Valve RVP

Price range: $66 through $229Check Valve RVP

Applications in Hydraulic Systems: The RVP type check valve finds widespread utility in hydraulic systems, primarily at the outlet of pumps. Here, it serves a dual purpose as a back pressure valve and bypass valve. As a back pressure valve, it helps regulate the pressure within the hydraulic circuit, ensuring optimal performance and preventing potential damage due to excessive pressure. Simultaneously, its role as a bypass valve allows for the controlled diversion of fluid when needed, adding flexibility to the hydraulic setup.

-

check valve s

Price range: $8 through $38check valve s

A check valve, also known as a non-return valve or one-way valve, is designed to allow fluid to flow in only one direction through a pipeline. This valve is crucial for preventing backflow, which is the reverse flow of fluids that can lead to contamination and inefficiency in the system. Historically, it have been utilized since ancient times, primarily in water control for irrigation systems. Their design and functionality have evolved significantly, making them indispensable in modern industries such as oil and gas, chemical processing, water treatment, and HVAC systems .

-

Check Valve Sl

Price range: $7 through $206Check Valve Sl

The Aisun Model SL check valve is a high-performance hydraulic valve designed to prevent the reverse flow of fluid in a hydraulic circuit. It allows fluid to flow in one direction while automatically blocking any fluid flow in the opposite direction. This prevents damage to pumps, motors, and other components in the system that could be caused by backflow.

-

Check Valve Sv

Price range: $62 through $209Check Valve Sv

The Aisun Model Sv check valve is a high-performance hydraulic valve designed to prevent the reverse flow of fluid in a hydraulic circuit. It allows fluid to flow in one direction while automatically blocking any fluid flow in the opposite direction. This prevents damage to pumps, motors, and other components in the system that could be caused by backflow.

-

Modular Check Valve Z1S

Price range: $48 through $79Modular Check Valve Z1S

The Z1S type valve is a direct operated check valve with a modular structure. This check valve is closed without leakage in one direction and allows free flflow in the other direction.

The stroke of the conical spool (3) is limited by the spring seat (4). The spring (5) causes the conical spool(3) to close. When there is no flfluid flflows through the valve, the spring (5) holds the conical spool (3) inthe closed position.

Model Z1S10…3XJ/V (metal-sealed) This valve has a metallic seal between the conical spool (3) and the valve body (1). Therefore, it is,particularly suitable for condition of working pressure higher than 100bar and the flflow rate greater than 4m/s.

-

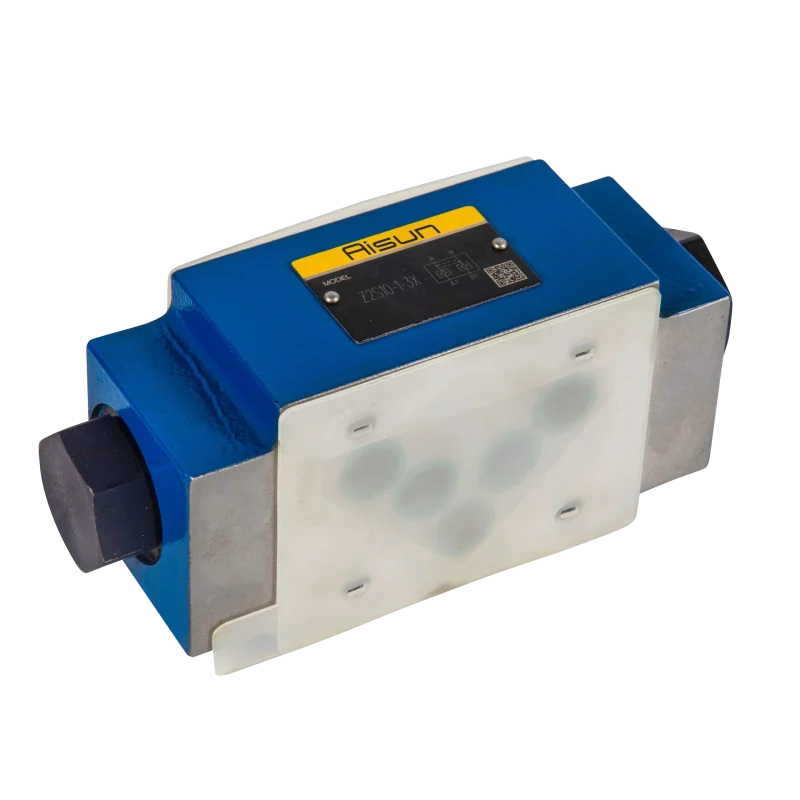

Modular Check Valve Z2S

Price range: $9 through $232Modular Check Valve Z2S

In the realm of hydraulic systems, precision control and reliability are paramount. The Z2S type modular hydraulic operated check valve emerges as a pivotal component in this landscape, featuring a sandwich plate design and excelling in providing leakage-free closure for one or two actuator ports, even during extended standstill periods. This article aims to unravel the intricate workings of the Z2S6 valve, shedding light on its design principles, operational mechanisms, and applications within hydraulic systems.

The Z2S6 valve stands as a pilot-operated check valve, ingeniously crafted in a sandwich plate design. Its primary function is to ensure the seamless closure of actuator ports, preventing any undesired fluid flow during prolonged periods of inactivity. The valve allows for unimpeded fluid flow in the A1 to A2 or B1 to B2 direction, and conversely, it efficiently blocks flow in the opposite direction. -

Plug-in check valve M-SR

Price range: $80 through $240Plug-in check valve M-SR

The primary function of a check valve in a hydraulic system is to allow fluid to flow in one direction only while blocking the flow in the opposite direction.

When fluid enters through port p1, the pressure at p1 overcomes the pressure at port p2 acting on the valve core, along with the spring force and friction between the valve core and the valve body, pushing the valve core open and allowing fluid to flow from p1 to p2, achieving forward flow. Conversely, when pressure oil enters from port p2, the valve core is pressed tightly against the valve seat by the combined action of the liquid pressure at p2 and the spring force, blocking the fluid flow and achieving reverse flow cutoff.Features:

- Size 8 to 30

- Maximum working pressure 315 bar

- Maximum working flflow 400 L/min

- Insert into the manifolds blocks

- Reverse closing without leakage

- 6 optional cracking pressure