Hydraulic proportional valves are advanced components used in hydraulic systems to control the flow and pressure of hydraulic fluid with a high degree of accuracy. Unlike traditional on/off valves, proportional valves can modulate the flow rate and pressure in response to electrical signals, allowing for smoother and more precise control of hydraulic actuators such as cylinders and motors. Here’s a detailed explanation of hydraulic proportional valves, including their types, functions, advantages, and applications.

Types of Hydraulic Proportional Valves

1. Proportional Flow Control Valves:

– Function: These valves regulate the flow rate of hydraulic fluid to an actuator based on the input signal, which is typically an electrical voltage or current.

– Operation: The valve’s spool position is proportional to the input signal, allowing for variable flow rates. This enables precise control over speed and movement of hydraulic cylinders.

2. Proportional Pressure Control Valves:

– Function: These valves modulate the pressure in the system based on an electrical input signal.

– Operation: They adjust the opening of the valve to maintain a set pressure level. When the pressure exceeds a predetermined limit, the valve opens to relieve excess pressure, thus maintaining system safety and performance.

3. Proportional Directional Control Valves:

– Function: These valves control the direction of hydraulic fluid flow in addition to the flow rate.

– Operation: By adjusting the valve’s spool position in response to an electrical signal, they can direct fluid to different hydraulic circuits, enabling complex movements of machinery.

-

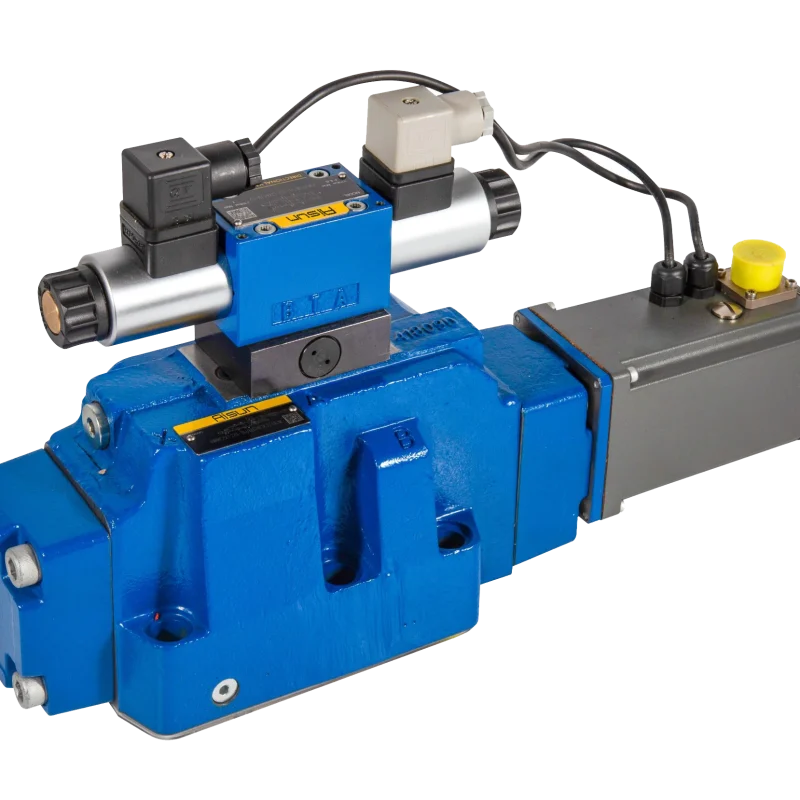

hydraulic Proportional Directional valves 4WRKE

Price range: $1.642 through $2.687Proportional Directional valves 4WRKE

In the field of fluid power control, the Electro-Hydraulic Proportional Directional Valve (EHPDV) is a critical component that plays a vital role in regulating the flow and direction of hydraulic fluids. Among the various types of EHPDVs available, the 4WRK… stands out as a high-performance, two-stage proportional directional control valve. This valve offers precise control over flow size and direction, making it an ideal choice for applications requiring accurate hydraulic control.

The 4WRKE type proportional directional control valve comprises several key components, including the pilot control valve, housing, main spool, covers, centering spring, inductive position transducer, and pressure reducing valve. Each component serves a specific purpose in ensuring the valve’s smooth operation and precise control over fluid flow. -

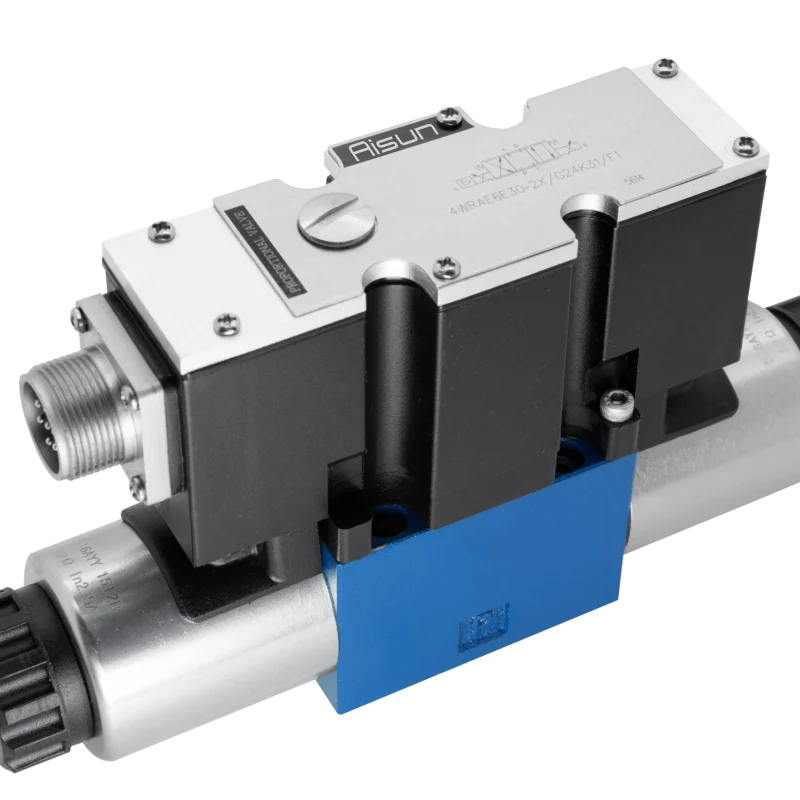

hydraulic Proportional Directional valves 4WRPEH

Price range: $1.374 through $1.702Proportional Directional valves 4WRPEH

The 4WRPEH high-response Proportional Directional Servo Valve, showcasing the advanced 4WRPEH6 variant, represents a remarkable achievement in fluid control systems. This pilot-operated directional control valve combines cutting-edge technology with precise construction elements to achieve unparalleled operational efficiency.

- Proportional Directional Servo Valve

- With control spool and sleeve in servo quality

- Operated on one side, 4/4-fail-safe position in switched off state

- Electric position feedback and integrated

- electronics(OBE), calibrated in the factory

- Electrical connection 6P+PE signal input differential amplifier with interface’ ‘A1″:土10V or interface’ ‘F1″: 4..20mA (Rsh =2000)

- Subplate mounting

- porting pattern to ISO 4401-03-02

-

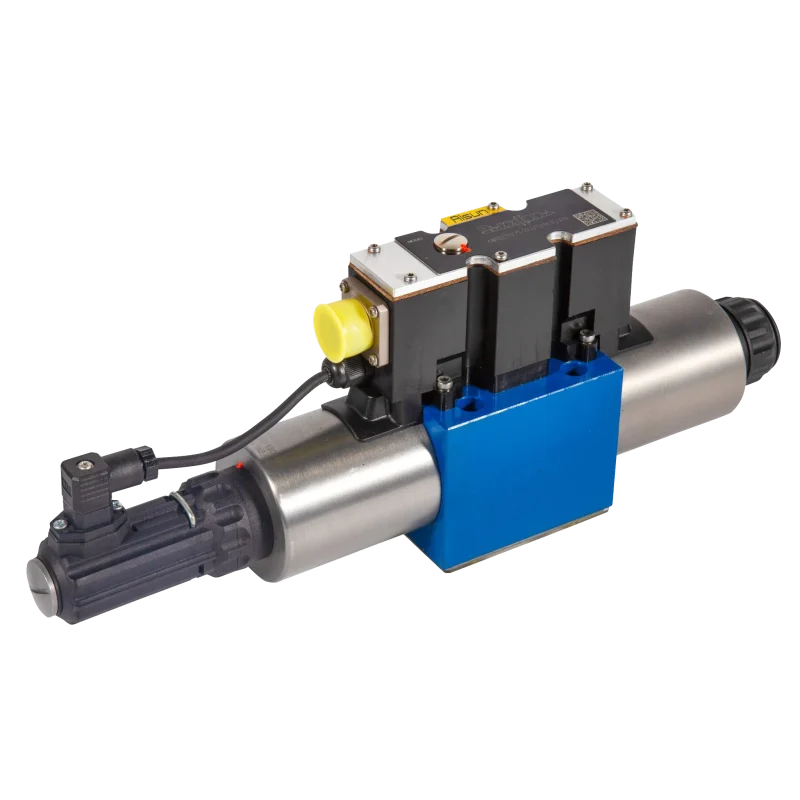

Proportional directional valves 4WRA

Price range: $424 through $1.081Proportional directional valves 4WRA

Proportional directional valves 4WRA are capable of controlling the direction and flow of the hydraulic system according to the polarity and amplitude of the input electrical signal, thus realising the control of the direction and speed of the movement of the actuating elements.

- Size 6 and 10

- Maximum working pressure 315 bar

- Maximum working flflow 42 L/min (size 6)

- 75 L/min (size 10)

- Proportional direction valve with direct operated proportional solenoid

- For subplate mounting

- Control the direction and flow

- Spring centred control spool

- Both valves and proportional amplififiers from the same supplier

-

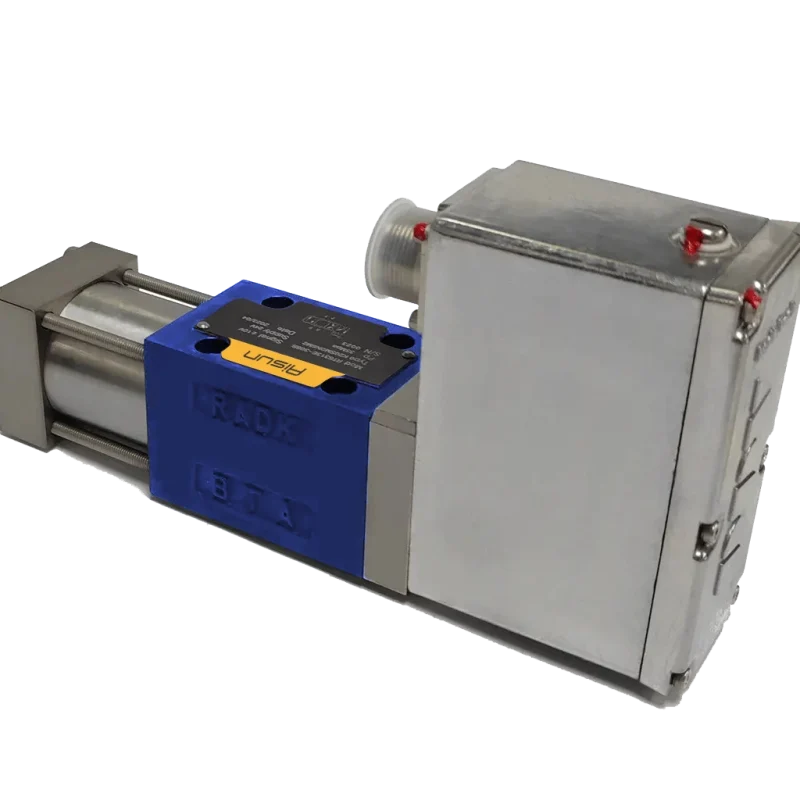

Proportional directional valves 4WRE

Price range: $663 through $1.351Proportional directional valves 4WRE

The 4WRE(E) type Proportional Control Valve is a highly advanced and efficient valve used in fluid control systems. It is designed with various components that work together to provide precise and adaptable control.

- Direct operated proportional directional

- valve with electrical position feedback

- Closed loop control of the direction and size of a flow

- Operation is by proportional solenoids with a central thread and removable coil

- For subplate mounting: Porting pattern conforms to ISO 4401

- Spring centred control spool

- Integrated electronics (OBE) with voltage

- input or current input (A1 resp. F1)

- 4WRE separate order: analogue module amplifier

-

Proportional Directional valves D633-D634

Price range: $2.761 through $3.312Proportional Directional valves D633-D634

The hydraulic servo valves D633 and D634 are typically high-precision components used in hydraulic control systems to manage the flow and direction of hydraulic fluid in applications that require precise movement and control. These valves are a series of hydraulic servo valves and are often used in industries such as aerospace, manufacturing, and heavy machinery.