Hydraulic pressure control valves are essential components in hydraulic systems, used to manage and regulate the pressure within the system. These valves help ensure that the hydraulic fluid operates within safe and efficient pressure ranges, protecting the system from damage and improving overall performance. Here are some key aspects of hydraulic pressure control valves:

Types of Hydraulic Pressure Control Valves

1. Relief Valves:

– Function: Protect the system from overpressure by allowing excess fluid to escape when the pressure exceeds a predetermined limit.

– Operation: When the system pressure reaches a set point, the valve opens, diverting fluid back to the reservoir or allowing it to bypass, preventing damage to components.

2. Reducing Valves:

– Function: Maintain a lower downstream pressure than the upstream pressure. They are used when a specific pressure is required in part of the system.

– Operation: These valves adjust their opening based on the downstream pressure, ensuring it remains at the desired level.

3. Sequence Valves:

– Function: Control the sequence of operations in a hydraulic system by directing flow to one circuit before another can operate.

– Operation: They open when a specified upstream pressure is reached, allowing fluid to flow to the next component in the sequence.

4. Counterbalance Valves:

– Function: Maintain load stability in hydraulic systems, especially in applications involving lifting or lowering.

– Operation: These valves prevent unexpected motion by maintaining a set pressure on the load side, allowing controlled movement.

-

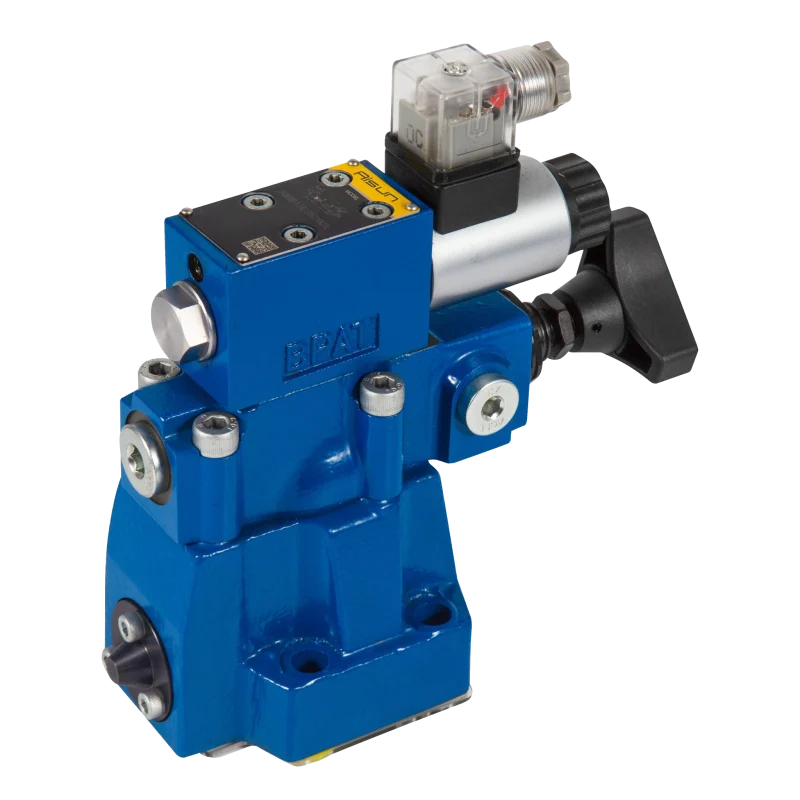

Pressure control valves DB and DBW

Price range: $138 through $285Pressure control valves DB and DBW

The DB and DBW pressure control valves are pilot operated relief valves.

They are used to limit (DB), or to limit and unload by solenoids (DBW) of working pressure.

- ◆ Size 10 to 32

- ◆ Maximum working pressure 350 bar

- ◆ Maximum working flow 650L/min

- ◆Subplate mounting: size 10/20/30

- ◆Threaded connection:size 10/15/20/25/32

- ◆Setting pressure:5MPa/10MPa/20MPa/31.5bar/35MPa

- ◆Flow rate:250L/min (for size 10 only),500L/min (for size 15, 20, 25),650L/min (for size 32 only)

-

Pressure relief valve DBD

Price range: $44 through $217Pressure relief valve DBD

The DBD hydraulic pressure relief valve is direct operated, it is used to limit the pressure of hydraulic system. Features:

- Inserted cartridge

- Threaded connection

- Subplate mounting

- 3 pressure adjustment elements

-Inner hexagon adjusting screw with -protective cap -Adjusting handle -Adjusting handle with lock

The DBD hydraulic pressure relief valve is a crucial component used to regulate and control the pressure in hydraulic systems. Its direct operation ensures efficient and accurate pressure limitation, preventing any potential damage or failure within the system.