Hydraulic directional control valves are used to control the flow of hydraulic fluid in a hydraulic system. These valves are responsible for directing the flow of fluid to different actuators or components within the system, allowing for precise control of the system’s operation.

There are several types of hydraulic directional control valves, including:

Spool valves: These valves use a cylindrical spool that moves back and forth within a housing to control the flow of fluid. The position of the spool determines which ports are open or closed, directing the flow of fluid accordingly.

Ball valves: These valves use a ball with a hole in it to control the flow of fluid. By rotating the ball, the flow can be directed to different ports within the valve.

Poppet valves: These valves use a poppet, or plunger, to control the flow of fluid. The poppet moves up and down within the valve to open or close ports, directing the flow of fluid as needed.

Hydraulic directional control valves are typically operated using a manual lever, knob, or switch, but can also be automated using solenoids or other electronic controls. These valves are essential for controlling the movement of hydraulic cylinders, motors, and other hydraulic components in a wide range of applications, including construction equipment, agricultural machinery, and industrial machinery.

-

Check Valve RVP

Price range: $66 through $229Check Valve RVP

Applications in Hydraulic Systems: The RVP type check valve finds widespread utility in hydraulic systems, primarily at the outlet of pumps. Here, it serves a dual purpose as a back pressure valve and bypass valve. As a back pressure valve, it helps regulate the pressure within the hydraulic circuit, ensuring optimal performance and preventing potential damage due to excessive pressure. Simultaneously, its role as a bypass valve allows for the controlled diversion of fluid when needed, adding flexibility to the hydraulic setup.

-

check valve s

Price range: $8 through $38check valve s

A check valve, also known as a non-return valve or one-way valve, is designed to allow fluid to flow in only one direction through a pipeline. This valve is crucial for preventing backflow, which is the reverse flow of fluids that can lead to contamination and inefficiency in the system. Historically, it have been utilized since ancient times, primarily in water control for irrigation systems. Their design and functionality have evolved significantly, making them indispensable in modern industries such as oil and gas, chemical processing, water treatment, and HVAC systems .

-

Check Valve Sl

Price range: $7 through $206Check Valve Sl

The Aisun Model SL check valve is a high-performance hydraulic valve designed to prevent the reverse flow of fluid in a hydraulic circuit. It allows fluid to flow in one direction while automatically blocking any fluid flow in the opposite direction. This prevents damage to pumps, motors, and other components in the system that could be caused by backflow.

-

Check Valve Sv

Price range: $62 through $209Check Valve Sv

The Aisun Model Sv check valve is a high-performance hydraulic valve designed to prevent the reverse flow of fluid in a hydraulic circuit. It allows fluid to flow in one direction while automatically blocking any fluid flow in the opposite direction. This prevents damage to pumps, motors, and other components in the system that could be caused by backflow.

-

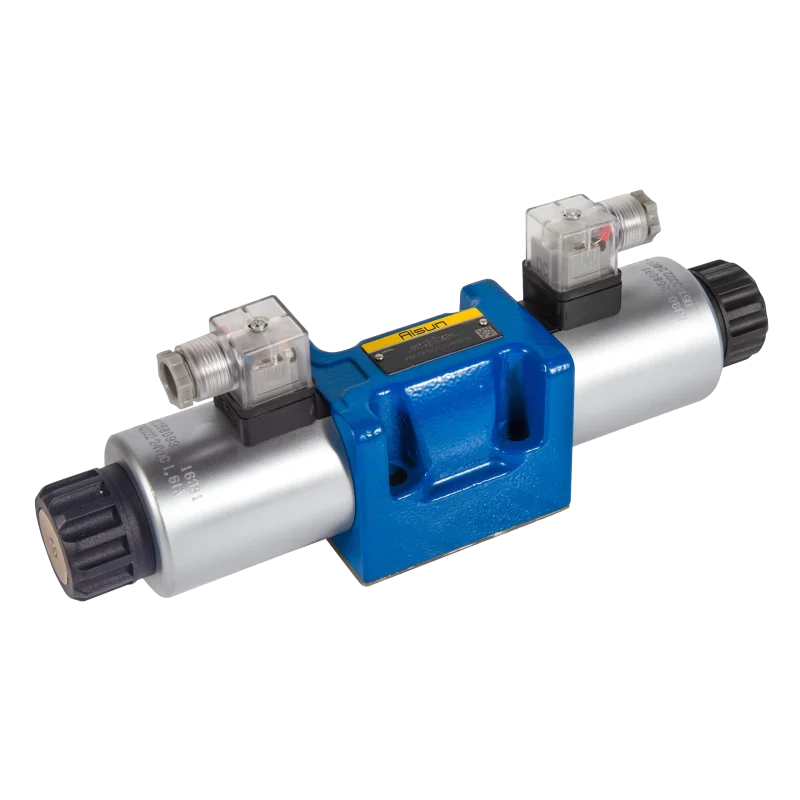

Directional Solenoid Valve 4we

Price range: $71 through $124Directional Solenoid Valve 4we

The 4WE Hydraulic Solenoid Directional Valve is a directional spool valve operated by the solenoid. It controls the opening, closing, and flow direction of the liquid flow. Features:

With the direct type solenoid operated directional spool valve as the standard type

Wet-pin DC or AC solenoids with detachable coil

The solenoid can be rotated by 90°

Replace the coil without releasing the oil

Individual or central electrical connection, optional

Optional manual emergency operation

The control input device of the Hydraulic Solenoid Directional Valve is a switching electromagnet, and the thrust generated when the electromagnet is energized makes the valve core do relative movement in the valve body to realize the reversing. The control signal of the solenoid valve can be directly controlled by the signal sent by the button switch, the stroke switch, the pressure relay and other components, and can also be controlled by the signal sent by the computer, the programmable controller and other control devices, which is convenient and widely used. -

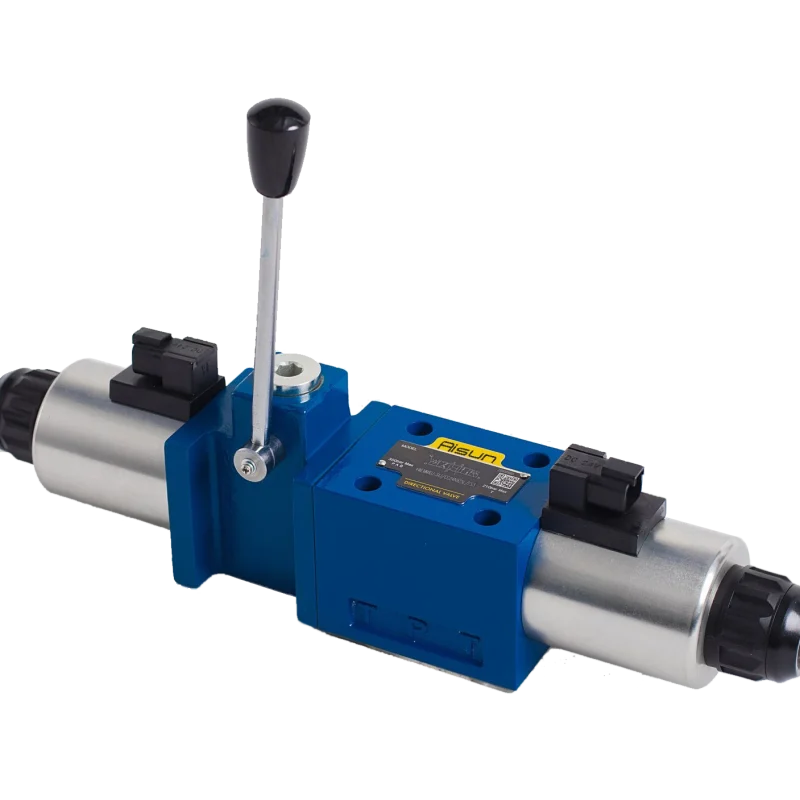

Directional spool valve WMM

Price range: $30 through $400Directional spool valve WMM

In the dynamic world of hydraulic systems, precise control over fluid flow is paramount. The WMM manual valve, specifically the manual directional valve, emerges as a crucial component that allows operators to seamlessly switch oil circuits through manual manipulation. This article aims to delve into the design intricacies, operational mechanisms, and diverse applications of the WMM series, shedding light on its pivotal role in hydraulic engineering.

WMM Manual Valve Overview: The WMM manual valve is a direct-operated directional spool valve designed to facilitate the switching of oil circuits by manually rotating the handle to axially move the spool. This versatile valve comes in 3/2-way, 4/2-way, and 4/3-way configurations, featuring various spool symbols.

The WMM series manual valve is renowned for its robust construction and reliable performance. Its design ensures efficient control over the flow of hydraulic fluids, making it an indispensable component in a wide range of applications. The valve body is made of high-quality materials, such as cast iron or aluminum alloy, which provide excellent durability and resistance to wear and tear. This ensures that the valve can withstand harsh operating conditions and maintain its functionality over a prolonged period.

-

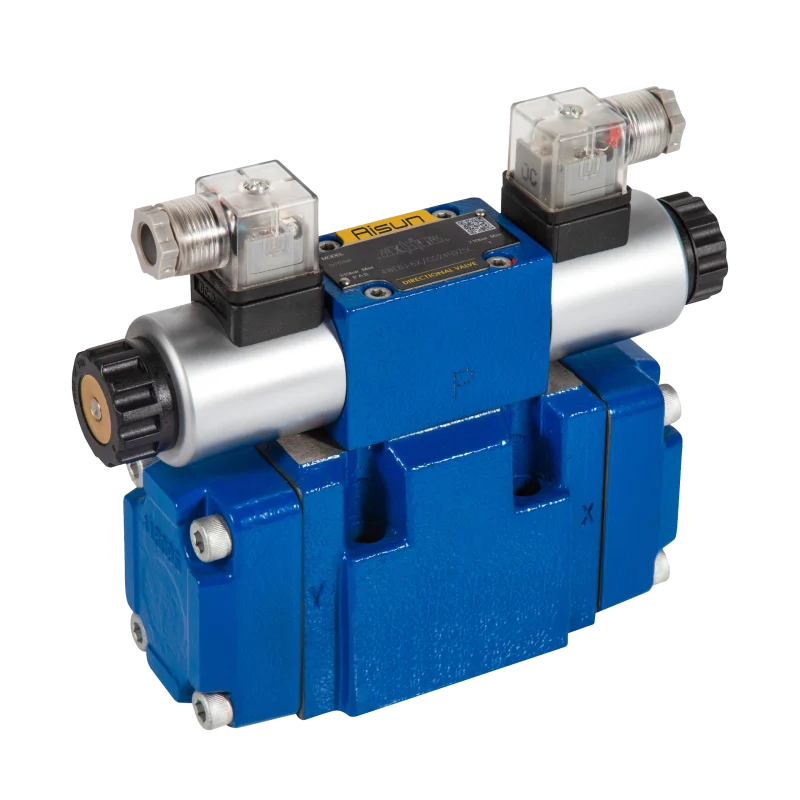

Directional spool valves 4WEMM

Price range: $168 through $194Directional spool valves 4WEMM

Applications in Hydraulic Systems: WEMM type directional spool valves find applications in scenarios where manual actuation is essential, especially during emergencies. The combination of solenoid operation and auxiliary handle control provides flexibility in fluid flow control, catering to diverse hydraulic system requirements.

In conclusion, the WEMM type directional spool valves represent a crucial advancement in hydraulic engineering, offering precise control with both solenoid and manual actuation options. Their versatile design and applications make them indispensable components in hydraulic systems, ensuring reliable performance and emergency response capabilities. As technology continues to evolve, these valves play a vital role in enhancing the efficiency and adaptability of hydraulic systems across various industries. Engineers and practitioners must grasp the intricacies of WEMM type valves to harness their full potential and contribute to the evolving landscape of hydraulic technology.

-

Electro-Hydraulic Directional Valves WEH

Price range: $100 through $632Electro-Hydraulic Directional Valves WEH

WEH Series – Electro-Hydraulic Directional Spool Valve: The WEH series represents a class of directional spool valves featuring Control Valve electro-hydraulic operation. These valves take command of the initiation, cessation, and direction of fluid flow within hydraulic circuits. The core components include the main valve body, main valve spool, one or two return springs, and the pilot valve equipped with one or two solenoids.

Features

- -Control Valve Electro-Hydraulic Operated

- – Valves used to control the start, stop and

- direction of a fluid flow

- – Electro-hydraulic operation (WEH)

- – Hydraulic operation (WH)

- – Subplate mounting

- porting pattern conforms to DIN24340 form A and ISO4401

- – Spring or pressure centered, spring or hydraulic offset

- – Wet pin DC or AC solenoids, optional

- – Hand override, optional

- – Electrical connection as an individual or

- central connection

- – Shifting time adjustment, optional

- – Pre-loading valve in the P-channel of the main valve, optional

- – Auxiliary equipment to data sheet

- – Stroke adjustment at main spool, optional

- – Stroke adjustment and/or end position indicator, optional

- Mechanical or inductive limit switch

- (proximity type) at the main spool

-

Modular Check Valve Z1S

Price range: $48 through $79Modular Check Valve Z1S

The Z1S type valve is a direct operated check valve with a modular structure. This check valve is closed without leakage in one direction and allows free flflow in the other direction.

The stroke of the conical spool (3) is limited by the spring seat (4). The spring (5) causes the conical spool(3) to close. When there is no flfluid flflows through the valve, the spring (5) holds the conical spool (3) inthe closed position.

Model Z1S10…3XJ/V (metal-sealed) This valve has a metallic seal between the conical spool (3) and the valve body (1). Therefore, it is,particularly suitable for condition of working pressure higher than 100bar and the flflow rate greater than 4m/s.

-

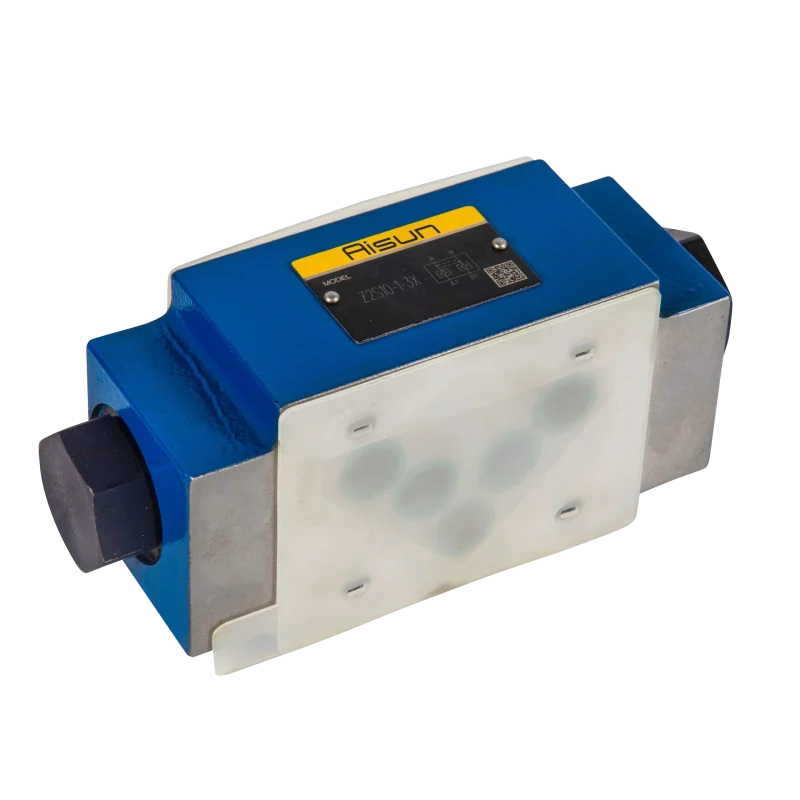

Modular Check Valve Z2S

Price range: $9 through $232Modular Check Valve Z2S

In the realm of hydraulic systems, precision control and reliability are paramount. The Z2S type modular hydraulic operated check valve emerges as a pivotal component in this landscape, featuring a sandwich plate design and excelling in providing leakage-free closure for one or two actuator ports, even during extended standstill periods. This article aims to unravel the intricate workings of the Z2S6 valve, shedding light on its design principles, operational mechanisms, and applications within hydraulic systems.

The Z2S6 valve stands as a pilot-operated check valve, ingeniously crafted in a sandwich plate design. Its primary function is to ensure the seamless closure of actuator ports, preventing any undesired fluid flow during prolonged periods of inactivity. The valve allows for unimpeded fluid flow in the A1 to A2 or B1 to B2 direction, and conversely, it efficiently blocks flow in the opposite direction. -

Plug-in check valve M-SR

Price range: $80 through $240Plug-in check valve M-SR

The primary function of a check valve in a hydraulic system is to allow fluid to flow in one direction only while blocking the flow in the opposite direction.

When fluid enters through port p1, the pressure at p1 overcomes the pressure at port p2 acting on the valve core, along with the spring force and friction between the valve core and the valve body, pushing the valve core open and allowing fluid to flow from p1 to p2, achieving forward flow. Conversely, when pressure oil enters from port p2, the valve core is pressed tightly against the valve seat by the combined action of the liquid pressure at p2 and the spring force, blocking the fluid flow and achieving reverse flow cutoff.Features:

- Size 8 to 30

- Maximum working pressure 315 bar

- Maximum working flflow 400 L/min

- Insert into the manifolds blocks

- Reverse closing without leakage

- 6 optional cracking pressure

-

Solenoid Poppet Valve M-SED

Price range: $75 through $188Solenoid Poppet Valve M-SED

The M-SED type valve represents a solenoid actuation directional seat valve, boasting the capability to control the initiation, cessation, and direction of fluid flow. Comprising a valve housing, solenoid, valve seats, and a closing element, this valve is equipped with advanced features that make it an indispensable component in various hydraulic systems.

One of the primary advantages of the M-SED directional Poppet valve is its ability to provide precise and rapid control over fluid flow. This is achieved through the integration of a highly responsive solenoid, which generates a magnetic field to actuate the valve mechanism. The solenoid converts electrical energy into mechanical force, allowing for the precise movement of the valve’s closing element. As a result, the M-SED directional Poppet valve can effectively regulate fluid flow rates, enabling smooth and efficient operation of hydraulic systems.

Furthermore, the M-SED valve exhibits exceptional durability and reliability. Constructed with high-quality materials and designed with meticulous engineering, this valve can withstand harsh operating conditions, including high pressure and temperature environments. Its robust construction ensures long-lasting performance, minimizing downtime and maintenance costs in industrial applications.

The versatility of the M-SED valve is another aspect worth highlighting. With its modular design, this valve can be easily integrated into various hydraulic circuits, offering flexibility in system design and configuration. Additionally, the valve’s compatibility with different fluids makes it suitable for a wide range of applications across diverse industries, including manufacturing, construction, and agriculture.