hydraulic valve

April 28, 2025hydraulic cylinder

April 29, 2025📘 Hydraulic Pumps: Principles, Types, Applications, and Maintenance

💡 Introduction

Hydraulic systems are widely used in various industries to transmit and control power through pressurized fluids. At the heart of every hydraulic system lies the hydraulic pump, which plays a critical role in converting mechanical energy into hydraulic energy. This paper explores the principles, types, applications, and maintenance practices related to hydraulic pumps, offering a detailed understanding of their function and importance in modern engineering.

—

🔍 What is a Hydraulic System?

A hydraulic system uses an incompressible fluid—usually oil—to transmit force from one point to another within the system. These systems rely on Pascal’s Law, which states that pressure applied to a confined fluid is transmitted equally in all directions throughout the fluid.

This principle allows small forces to be amplified into large ones by changing the area over which the force is applied. For example, lifting a heavy vehicle with minimal effort using a hydraulic jack relies entirely on this law.

⚙ Fundamental Concepts

– Pressure: Force per unit area (measured in psi or bar).

– Flow Rate: Volume of fluid moved per unit time (often measured in GPM or LPM).

– Power: The product of pressure and flow rate.

– Efficiency: Ratio of output power to input power.

📊 Comparison with Pneumatic Systems

| Feature | Hydraulic System | Pneumatic System |

|——–|——————|——————-|

| Fluid | Oil (incompressible) | Air (compressible) |

| Precision | High | Moderate |

| Speed | Slower | Faster |

| Output Power | High | Moderate |

| Application | Heavy machinery | Light and precise operations |

—

🔁 What Is a Hydraulic Pump?

A hydraulic pump is a mechanical device that converts mechanical power into hydraulic energy. It does this by moving fluid through the system, creating the necessary pressure to operate cylinders, motors, and other components.

🧩 Main Components

– Housing or casing

– Rotating mechanism (gears, vanes, or pistons)

– Inlet and outlet ports

– Drive shaft

🔄 Working Principle

- Fluid enters the pump through the inlet port

- Mechanical action increases the fluid velocity and pressure.

- Pressurized fluid exits through the outlet port toward actuators.

The pump doesn’t generate pressure directly; it creates flow, and resistance to that flow generates pressure.

—

There are three primary categories of hydraulic pumps:

1️⃣ Gear Pumps

✅ Advantages:

– Simple design

– Durable

– Cost-effective

❌ Disadvantages:

– Fixed displacement

– High noise level

– Lower efficiency

📌 Application: General industrial use, mobile equipment

2️⃣ Vane Pumps

✅ Advantages:

– Smooth operation

– Quiet performance

– Good efficiency

❌ Disadvantages:

– Sensitive to contamination

– More expensive than gear pumps

📌 Application: Medium-pressure applications like agricultural machinery

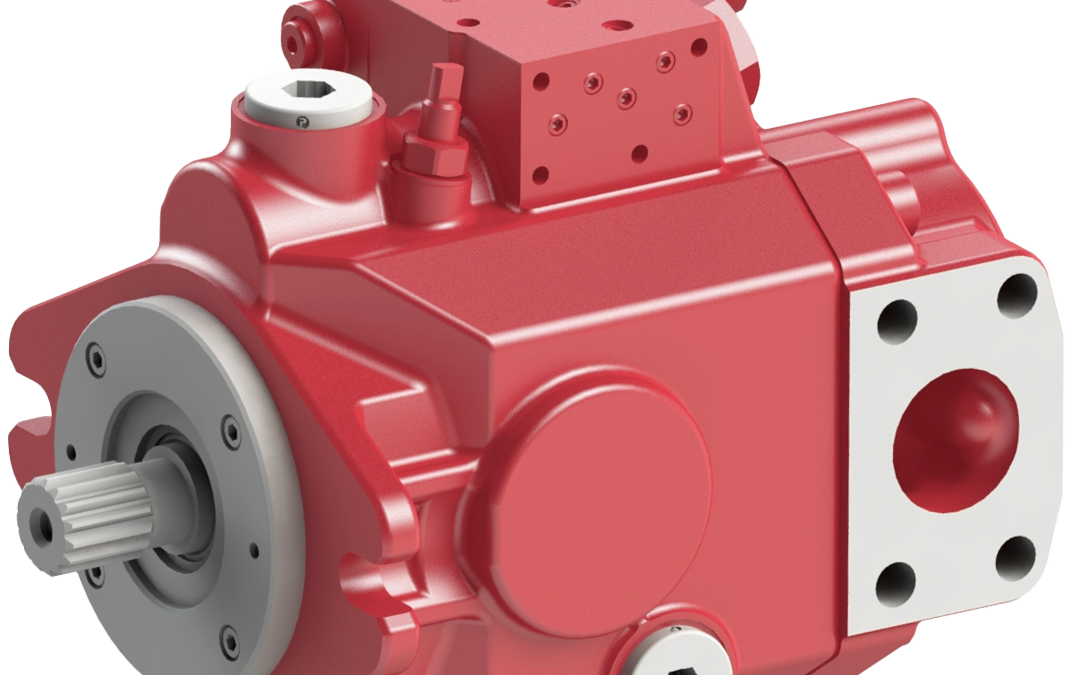

3️⃣ Piston Pumps

✅ Advantages:

– Variable displacement

– High pressure capability

– High efficiency

❌ Disadvantages:

– Complex design

– Expensive

– Requires regular maintenance

📌 Application: Aircraft, construction machinery, heavy-duty vehicles

—

Comparative Analysis of Hydraulic Pump Types

| Pump Type | Flow Control | Pressure Capability | Noise Level | Cost | Typical Use |

|———–|—————|———————|————-|——|————–|

| Gear | Fixed | Low | High | Low | General industry |

| Vane | Adjustable | Medium | Low | Medium | Agriculture |

| Piston | Variable | High | Low | High | Heavy machinery |

—

🛠️ Proper Installation Tips

– Ensure correct alignment between pump and motor

– Use proper seals and hoses

– Fill with recommended hydraulic fluid

– Install filters to protect internal components

🧼 Routine Maintenance Practices

– Regular oil changes

– Filter replacements

– Inspection of seals and couplings

– Monitoring pressure and flow rates

🔍 Common Signs of Pump Failure

– Loss of pressure or flow

– Unusual noise or vibration

– Overheating

– Oil leakage

🛠️ Troubleshooting Techniques

– Measure pressure with gauges

– Inspect fluid condition (color, smell, contamination)

– Check for cavitation or aeration

– Examine internal components for wear

—

Industrial Applications of Hydraulic Pumps

🚜 Agricultural Machinery

– Tractors

– Harvesters

– Sprayers

– Lift systems

🏗️ Construction Equipment

– Excavators

– Cranes

– Bulldozers

– Dump trucks

🚗 Automotive Industry

– Power steering systems

– Braking systems

– Vehicle lifts

✈ Aerospace Industry

– Flight control systems

– Landing gear actuation

– Emergency backup systems

—

Future Trends in Hydraulic Pump Technology

☁ Smart Hydraulic Pumps

Modern hydraulic pumps now incorporate digital sensors and controllers that allow for:

– Real-time monitoring

– Predictive maintenance

– Energy-efficient operation

♻ Green Hydraulic Systems

With increasing environmental awareness, manufacturers are adopting:

– Biodegradable hydraulic fluids

– Lightweight and durable materials

– Reduced emissions and waste

Hydraulic pumps are essential components in countless machines across multiple industries. Understanding their working principles, types, and maintenance needs is crucial for maximizing system performance and longevity. As technology evolves, we can expect smarter, more efficient, and environmentally friendly hydraulic systems, making continued education and innovation in this field vital.