hydraulic valve

April 28, 2025What is Industrial Hydraulics?

Introduction

Industrial hydraulics is a branch of mechanical engineering and technology that studies the use of fluids for the transmission of power and energy. This technology utilizes pressurized fluids (usually oil) to generate force, motion, and control in machinery and industrial equipment. Due to its ability to transmit high forces with precise control, hydraulics is widely used in various industries such as automotive, aerospace, mining, construction, and military applications.

—

Fundamental Principles of Hydraulics

- Pascal’s Law

Hydraulics operates based on Pascal’s Law, which states that pressure applied to an incompressible fluid in a closed system is transmitted equally in all directions. This principle allows hydraulic systems to transfer force efficiently and with high precision.

- Energy Transfer

In hydraulic systems, mechanical energy is converted into hydraulic energy by a pump. The pressurized fluid is then transferred through pipes and valves to different parts of the system, where it is converted back into mechanical energy to perform the desired work.

- Hydraulic Fluids

Hydraulic fluids play a critical role in the operation of hydraulic systems. These fluids not only transmit force but also provide lubrication, cooling, and protection against corrosion. Common hydraulic fluids include mineral oils, synthetic oils, and water-glycol mixtures.

—

Key Components of a Hydraulic System

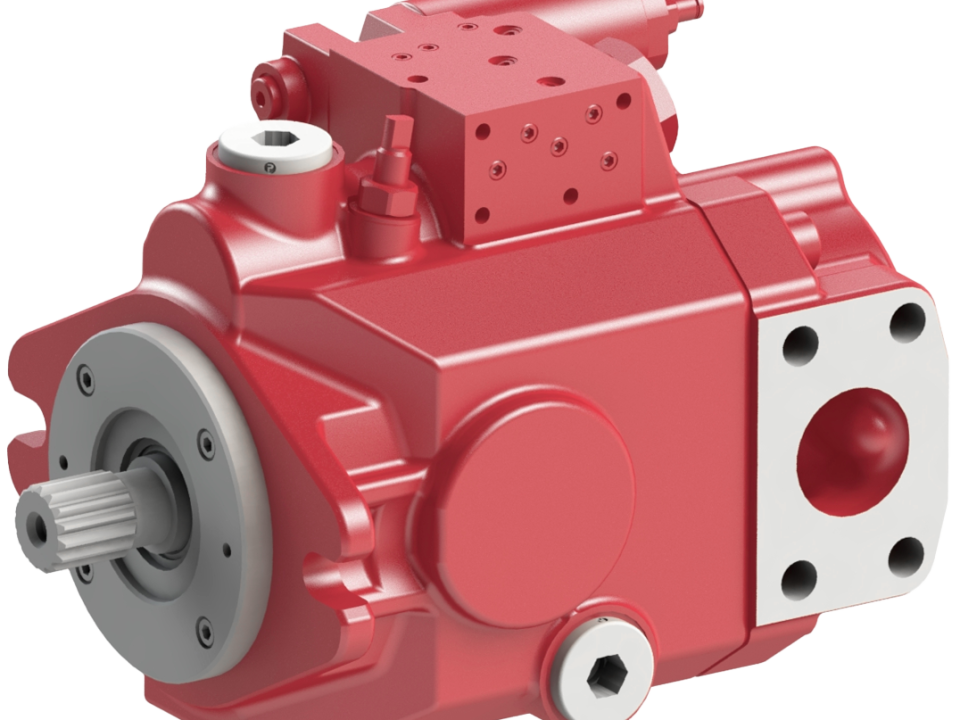

- Hydraulic Pump

The pump is responsible for converting mechanical energy into hydraulic energy. It pressurizes the fluid to create the flow necessary for system operation. Types of hydraulic pumps include gear pumps, vane pumps, and piston pumps.

- Fluid Reservoir

The reservoir stores the hydraulic fluid (usually oil). In addition to storage, it also serves to cool and filter the fluid, ensuring optimal performance.

- Hydraulic Cylinder

Cylinders convert hydraulic energy into linear or rotary motion. They consist of a piston and a cylinder body, and when pressure is applied to the fluid, linear motion is generated.

- Control Valves

Valves are used to regulate fluid flow, control pressure, and direct the movement of components. Types of valves include check valves, directional control valves, pressure control valves, and flow control valves.

- Pipes and Fittings

Pipes and fittings transport the fluid between different components of the system. These components must be highly resistant to pressure and temperature.

- Filters

Filters remove contaminants and maintain the fluid in optimal condition. Contamination can lead to component failure and reduce the system’s lifespan.

—

Advantages of Industrial Hydraulics

- High Force Transmission

Hydraulic systems can transmit very high forces in compact spaces, making them ideal for heavy-duty applications.

- Precise Control

They offer precise control over speed, pressure, and the position of moving components. This is particularly important in industries such as CNC machinery and robotics.

- Durability and Reliability

Hydraulic systems have fewer moving parts compared to other systems, resulting in longer lifespans. They also perform well under extreme environmental conditions, such as high or low temperatures.

- Ability to Handle Heavy Loads

These systems are highly suitable for heavy-duty applications in industries like mining and construction.

- Variable Speed

The operating speed of hydraulic systems can be adjusted without the need for physical component changes, providing greater flexibility.

—

Applications of Industrial Hydraulics

- Construction Machinery

Cranes, bulldozers, loaders, and excavators use hydraulic systems to lift and move heavy loads.

- Automotive Industry

Hydraulics are used in braking systems, power steering, and automatic transmissions. They are also employed in vehicle suspension systems.

- Aerospace

Hydraulic systems are used in landing gear control, braking systems, and rudder movement in aircraft. They are also used in opening and closing aircraft doors and landing gear operations.

- Marine Industry

Hydraulics are used in steering systems, anchor mechanisms, and lifting systems in ports and ships.

- Military Applications

Military equipment such as tanks, artillery, and lifting systems rely on hydraulics. They are also used in missile launch systems and vehicle control mechanisms.

- Manufacturing Industry

Hydraulics are used in plastic injection molding machines, hydraulic presses, and automated production lines. They are also employed in metal cutting and forming machinery.

—

Challenges and Disadvantages of Industrial Hydraulics

- High Initial Cost

Designing and setting up hydraulic systems can be expensive. Costs include equipment purchase, installation, and commissioning.

- Regular Maintenance Requirements

Hydraulic systems require periodic maintenance due to the use of fluids and mechanical components. Neglecting maintenance can lead to system failures.

- Environmental Pollution

Leakage of hydraulic fluids can cause environmental pollution. Additionally, the production and disposal of hydraulic fluids can have ecological impacts.

- Temperature Sensitivity

The performance of hydraulic systems is affected by temperature and may experience issues in extremely high or low temperatures.

—

The Future of Industrial Hydraulics

With technological advancements, hydraulic systems are evolving. The use of advanced materials, digital control systems, and integration with smart technologies (such as IoT) is driving hydraulic systems toward higher efficiency, lower energy consumption, and greater precision. Research is also underway to reduce environmental impacts and extend component lifespans.

—

Conclusion

Industrial hydraulics, as one of the most important technologies for power and energy transmission, plays a key role in the development of various industries. Despite existing challenges, this technology continues to be widely used due to its significant advantages. With ongoing technological advancements, the future of industrial hydraulics promises further improvements in efficiency, cost reduction, and minimized environmental impact.