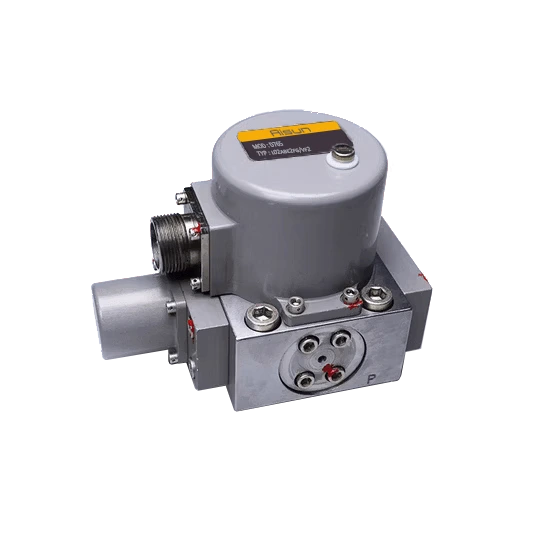

Servo Valve D765

The D765 hydraulic servo valve is another high-precision control valve used in hydraulic systems to regulate fluid flow in response to an electrical input signal. Similar to the D761, the D765 is part of the family of servo valves designed for demanding applications that require exact flow control, precise positioning, and fast response times. It is widely used in industrial, aerospace, and other high-performance sectors.

Features of the D765 Hydraulic Servo Valve:1. Proportional Control: The D765 is a proportional valve, meaning that the output flow and pressure are directly proportional to the input control signal (typically an electrical current or voltage). This allows for smooth and continuous control over the flow to hydraulic actuators like motors or cylinders. It provides fine control for both position and force, which is essential for applications that need accurate and smooth motion

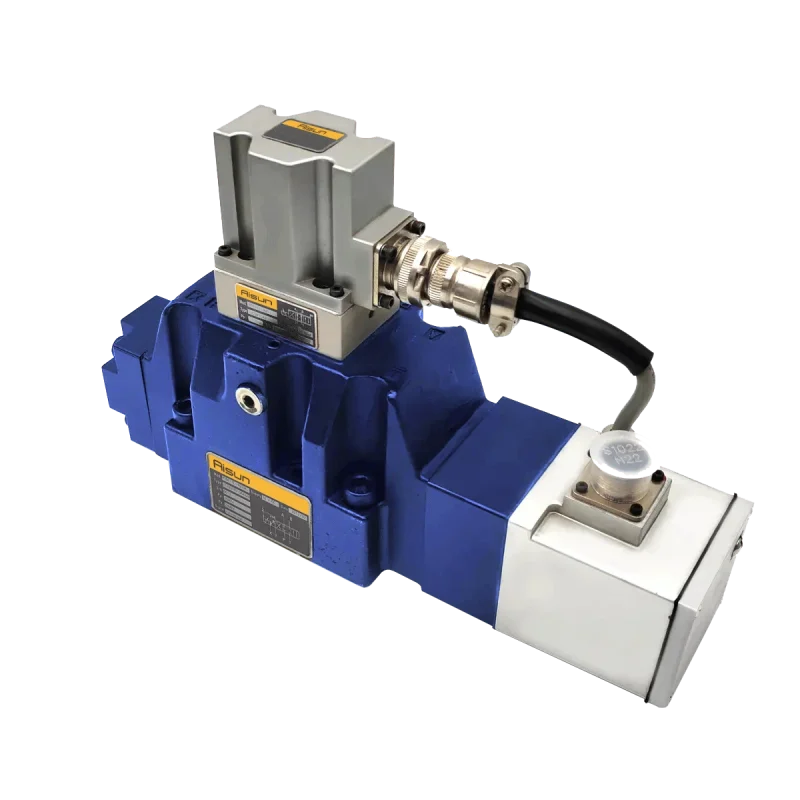

.2. High Precision: The D765 is designed for precise flow control, offering high resolution and minimal error in adjusting the hydraulic flow. It is ideal for applications where even small changes in flow can lead to significant changes in performance. It typically offers high repeatability and low hysteresis, meaning the valve responds consistently to control signals without delays or backlash

.3. Two-Stage Design: Like many advanced servo valves, the D765 may feature a two-stage design. The first stage is typically a precision metering valve (for small flow adjustments), while the second stage is a power stage designed to handle high flow rates. This architecture allows the valve to combine fine control with the ability to handle large amounts of fluid, making it versatile for a wide range of applications

.4. Feedback and Closed-Loop Control: The D765 often uses a feedback mechanism that monitors the position of the valve spool, ensuring that it remains in the desired position according to the input signal. The feedback system creates a closed-loop control system that continuously adjusts the valve operation to ensure accuracy and stability, particularly under varying load conditions.

5. Fast Response Time: The D765 valve is designed to have a fast response time, which is essential in systems where rapid adjustments are required, such as in aerospace control systems or precision robotics. This fast response time allows the system to maintain high performance even in dynamic environments where load changes or system disturbances may occur.

6. High Flow and Pressure Handling: The D765 series servo valves are capable of handling high-flow hydraulic systems, meaning they can supply sufficient hydraulic power for large actuators or systems with high power requirements. It is designed to function in high-pressure environments, making it suitable for applications that demand robust performance under extreme conditions.

7. Compact Design: Despite their high flow capacity, the D765 valves are often compact in design, making them suitable for applications where space is limited, such as in aerospace or military systems.

8. Application Areas: Aerospace: For flight control systems, where precision and rapid response are critical.

Robotics: For accurate control of robotic arms or other actuators requiring fine position adjustments. Industrial Automation: In CNC machines, test rigs, and other precision hydraulic systems.

Defense: For precise control in military vehicles or weapon systems, which demand both high power and accuracy. Advantages of the D765 Hydraulic Servo Valve:•

Precision: The D765 provides fine control of hydraulic flow, making it perfect for systems that require high accuracy in positioning and force control.• Fast and Dynamic Response: The fast response time allows it to adapt to dynamic changes in input or load conditions, making it ideal for real-time control.• Durability and Reliability: The D765 is built to handle demanding environments, including high-pressure and high-flow systems, ensuring reliability over long periods of operation.• Wide Range of Applications: Its versatility makes it suitable for a variety of industries, from aerospace to industrial automation, offering scalable performance for different system sizes and complexities.

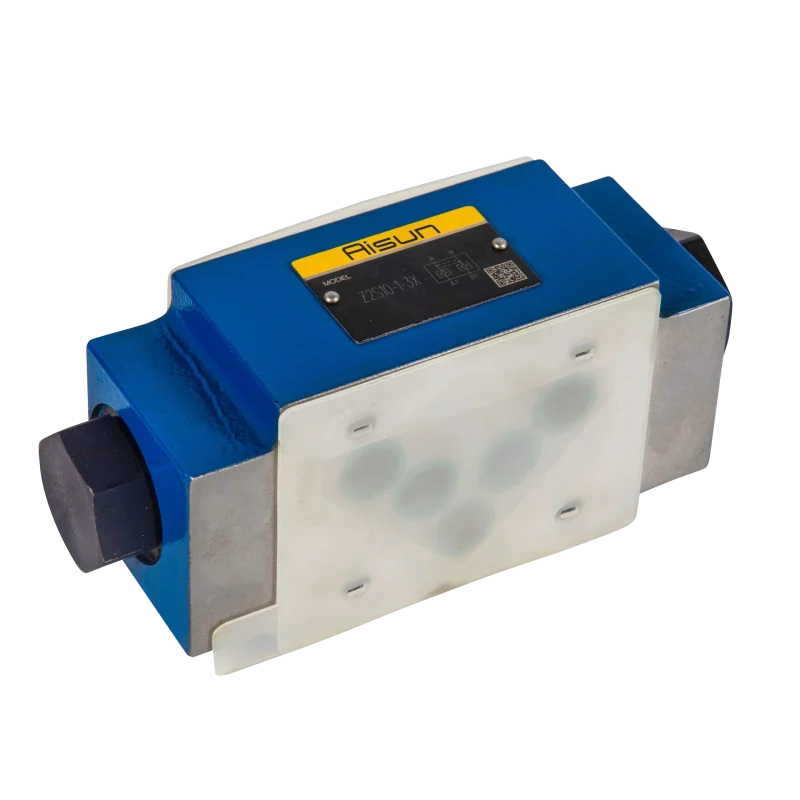

hydraulic Servo Directional valves D765

Servo Directional valves D765

The Servo Directional valves D765 is a precision valve commonly used in hydraulic control systems to regulate fluid flow in response to electrical input signals. It is part of the family of servo valves, which are designed to offer high-performance control in applications where precise motion or position control is required. These valves are used in a wide range of industries, including aerospace, industrial automation, robotics, and more.