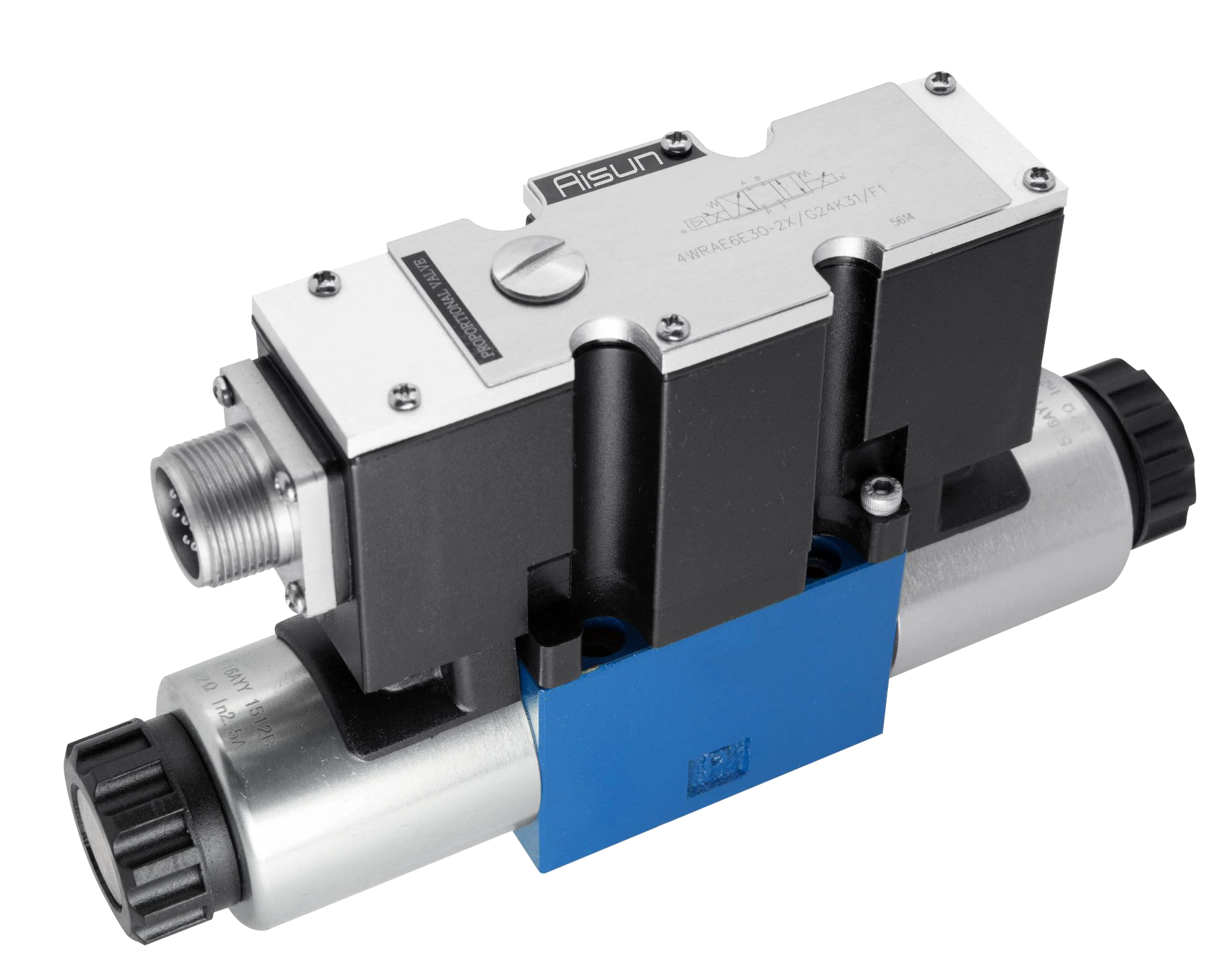

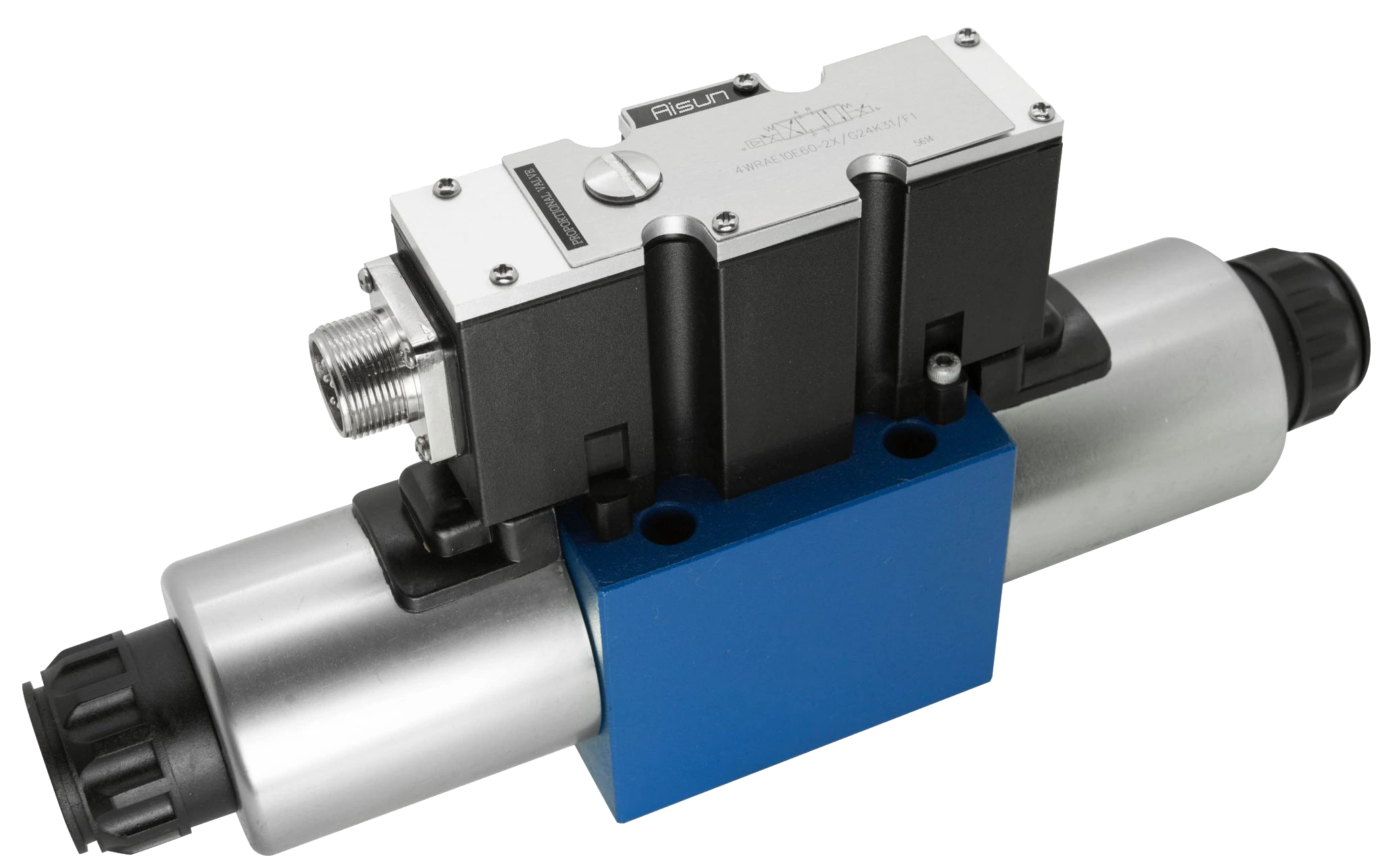

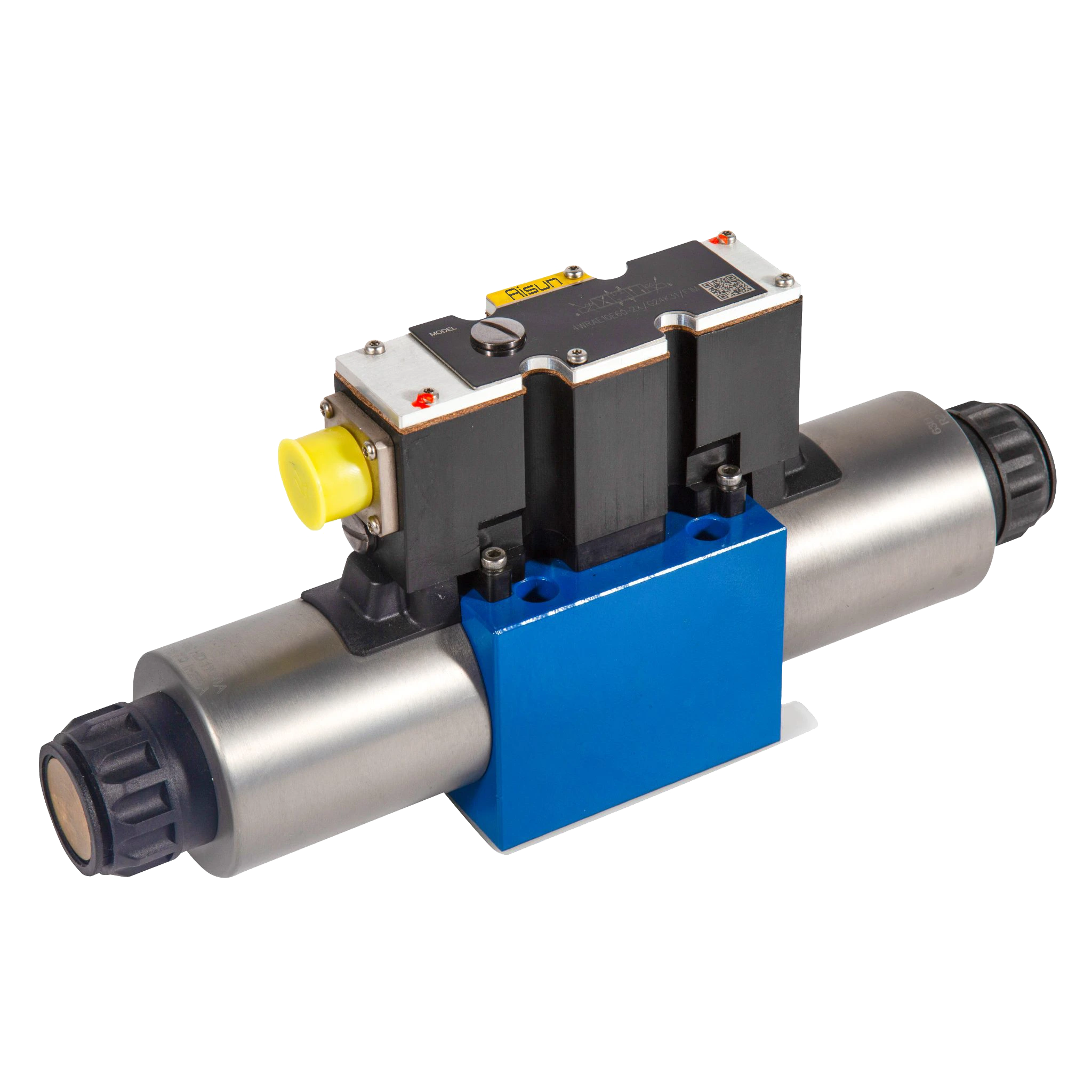

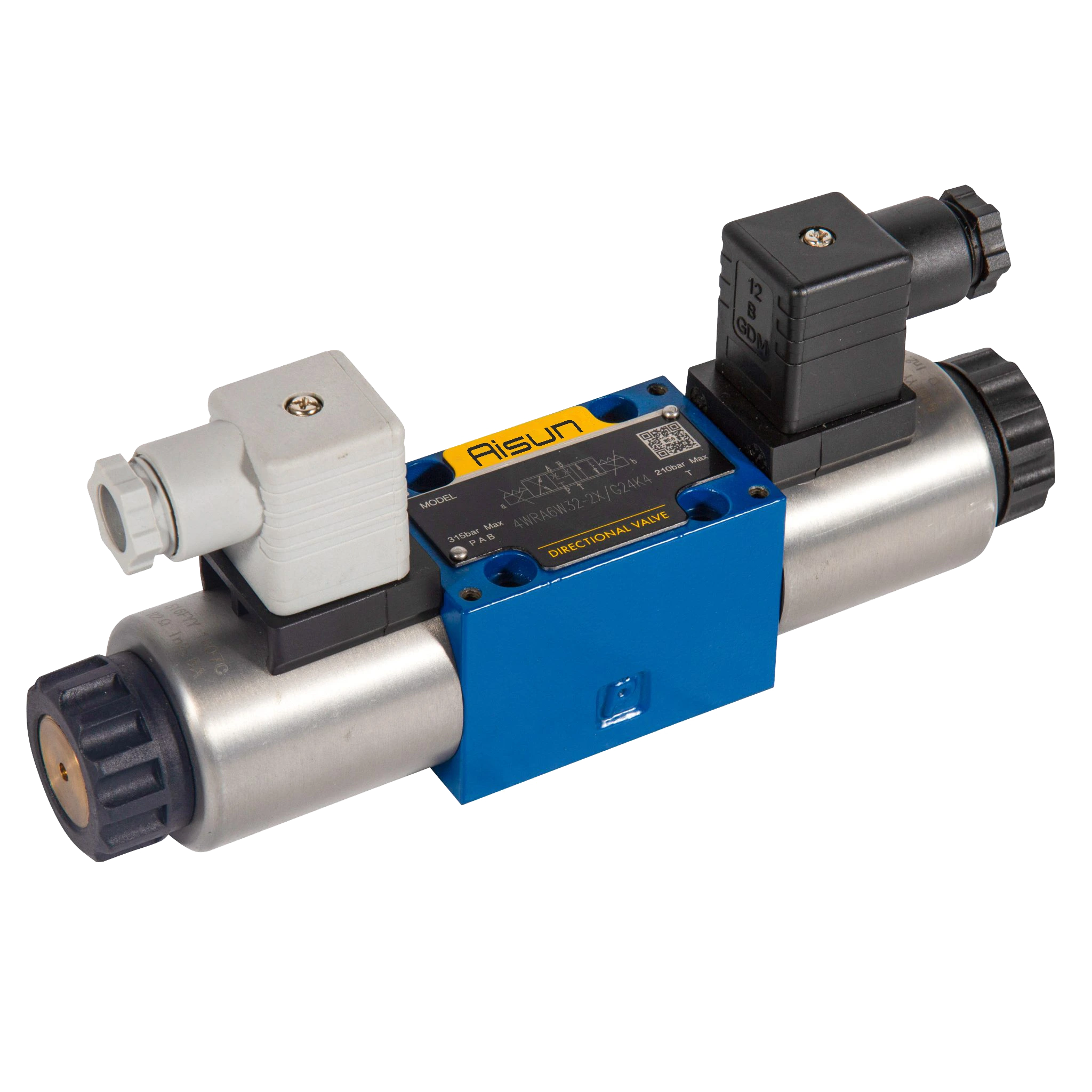

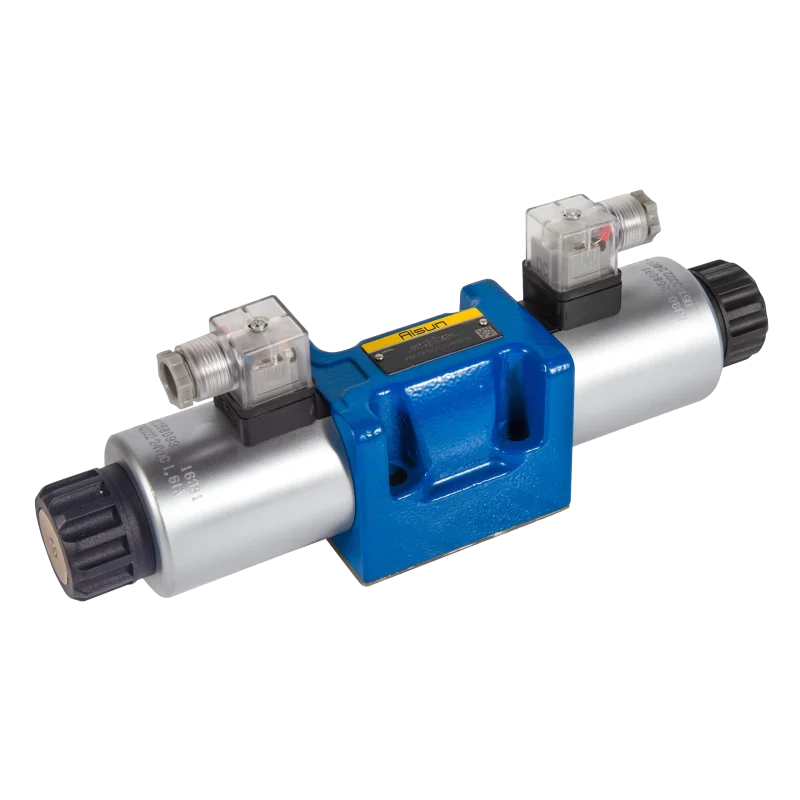

Proportional Directional Control Valve 4WRA

A 4WRA hydraulic valve is a type of proportional directional control valve commonly used in hydraulic systems. The 4WRA valve is designed to provide precise control over the flow and direction of hydraulic fluid, and it is particularly known for offering proportional control. These valves are commonly used in applications requiring high precision, such as in mobile machinery, industrial automation, and hydraulic test systems.

Let’s break down the key characteristics and operation of the 4WRA hydraulic proportional valve:

What is a 4WRA Hydraulic Proportional Valve?

The 4WRA is a 4-way, 3-position proportional directional control valve. The designation 4WRA typically refers to a specific series or model of proportional valve that uses electro-hydraulic or electronic control to modulate the flow and direction of hydraulic fluid.

- 4-way: This refers to the number of flow paths in the valve. It has four ports for fluid entry and exit.

- 3-position: This indicates the number of positions the valve can assume, typically including one neutral (center) position and two other flow directing positions.

- Proportional: This means that the valve does not just open or close; it can modulate the amount of fluid flowing through the valve based on an input signal (usually electric), providing fine control over fluid flow, speed, and direction.

Key Features and Working Principle

- Proportional Control:

- The 4WRA valve uses a proportional solenoid or electro-hydraulic actuator to control the movement of the valve spool. This solenoid adjusts the valve spool’s position based on an electrical input (often a current or voltage signal), allowing for proportional control of fluid flow.

- Unlike conventional valves, which are either open or closed, a proportional valve enables a continuous range of flow control. As the input signal changes, the valve opens incrementally, regulating the amount of hydraulic fluid passing through it.

- Flow Control:

- The amount of flow allowed through the valve depends on the position of the valve spool. When the solenoid receives a higher input signal, the valve spool moves more, allowing more fluid to pass. Conversely, a lower signal causes less movement of the spool, restricting fluid flow.

- This allows for precise control over actuator speeds (such as hydraulic cylinders or motors) and fine adjustments to system performance.

- 4-Way Valve:

- A 4WRA valve has four ports:

- P (Pressure): The inlet port where pressurized fluid enters.

- T (Tank): The return port where fluid exits to the reservoir or tank.

- A and B (Workports): These are the ports through which the hydraulic fluid is directed to actuators (such as cylinders or motors) depending on the valve’s position.

- A 4WRA valve has four ports:

- 3-Position Design:

- The valve typically has three positions:

- Neutral (center): In this position, the valve typically blocks the flow, and no fluid is directed to the actuators.

- Position 1 (Flow Direction 1): In this position, the valve allows fluid from the pressure port (P) to flow to workport A, while fluid from workport B is returned to the tank.

- Position 2 (Flow Direction 2): In this position, the valve allows fluid from the pressure port (P) to flow to workport B, while fluid from workport A is returned to the tank.

- The exact configuration of the valve may vary (e.g., flow may be bi-directional), but the key feature is that the valve is capable of modulating flow direction and flow rate in each position.

- The valve typically has three positions:

Proportional Control and Applications

The proportional aspect of the 4WRA valve provides significant advantages over traditional on/off valves:

- Precision Control: Because the valve is capable of varying flow rates based on the input signal, it allows for more precise control of hydraulic actuators (such as cylinders or motors), enabling fine adjustments to speed and force.

- Improved Performance: Proportional valves enable smoother transitions and adjustments in hydraulic systems, reducing shock loads and improving system stability.

- Energy Efficiency: Proportional control allows the system to adapt to varying load conditions, reducing unnecessary energy consumption by providing just the amount of flow needed for the task.

Applications of the 4WRA Proportional Valve

- Hydraulic Cylinders and Actuators:

- The 4WRA valve is commonly used to control the movement of hydraulic cylinders in both directions. Its ability to modulate the flow ensures smooth acceleration, deceleration, and position control of actuators.

- Hydraulic Motors:

- The valve is also used in controlling the direction and speed of hydraulic motors, which are often used in driving equipment such as conveyor belts, winches, and other machinery.

- Mobile Equipment:

- The 4WRA valve is widely used in construction machinery, agricultural equipment, and material handling machines to control hydraulic movements with precision.

- Robotics:

- In automated systems, robotics, or CNC machines, the precise control of hydraulic actuators is essential for high accuracy. The 4WRA valve can provide this level of control in the hydraulic systems powering robotic arms or other automated machinery.

- Industrial Automation:

- Proportional valves like the 4WRA are used in industrial presses, die-casting machines, plastic injection molding, and other industrial automation systems that require fine control of fluid power to regulate the speed and force of operations.

Summary of 4WRA Hydraulic Proportional Valve:

- The 4WRA valve is a 4-way, 3-position proportional directional control valve.

- It provides precise control over the flow rate and direction of hydraulic fluid, modulating the flow based on an input signal (usually electric).

- Common applications include controlling hydraulic cylinders, motors, and other actuators in mobile machinery, industrial automation, and robotics, where smooth, precise, and efficient control is required.

Advantages of 4WRA Proportional Valves:

- High Precision: Enables fine control of flow, speed, and force.

- Improved System Performance: Smooth operation and reduced shock loading.

- Energy Efficiency: Only the required amount of flow is provided based on the system’s needs.

The 4WRA hydraulic proportional valve is an important component in systems where precision, efficiency, and flexibility are critical, making it ideal for complex and high-performance hydraulic applications.

Proportional directional valves 4WRA

Proportional directional valves 4WRA

Proportional directional valves 4WRA are capable of controlling the direction and flow of the hydraulic system according to the polarity and amplitude of the input electrical signal, thus realising the control of the direction and speed of the movement of the actuating elements.

- Size 6 and 10

- Maximum working pressure 315 bar

- Maximum working flflow 42 L/min (size 6)

- 75 L/min (size 10)

- Proportional direction valve with direct operated proportional solenoid

- For subplate mounting

- Control the direction and flow

- Spring centred control spool

- Both valves and proportional amplififiers from the same supplier